Hoist lifting device for molten steel ladle

A technology of ladle and reel, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of difficult maintenance and maintenance, high cost, complex structure of hydraulic jacking device, etc. uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

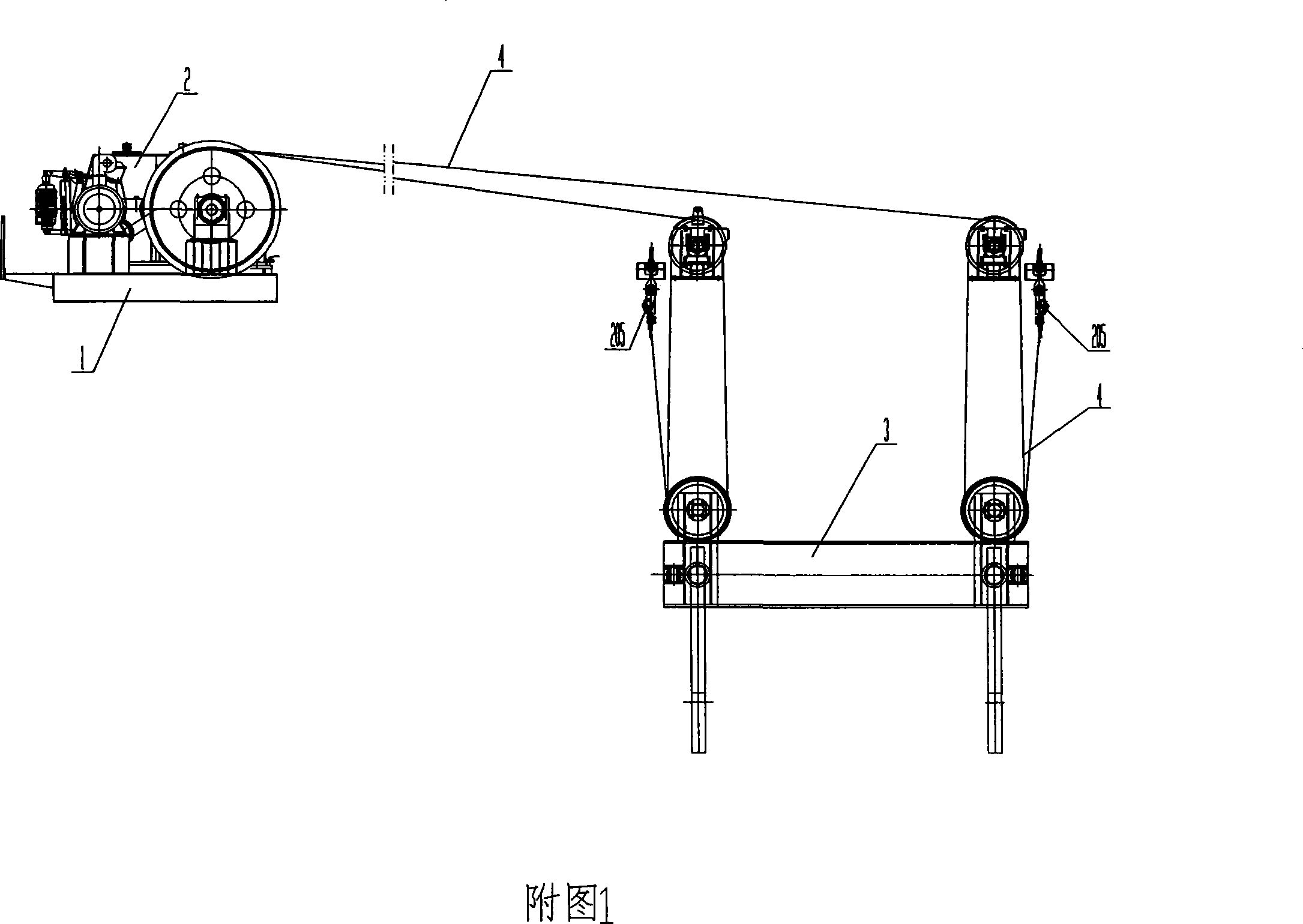

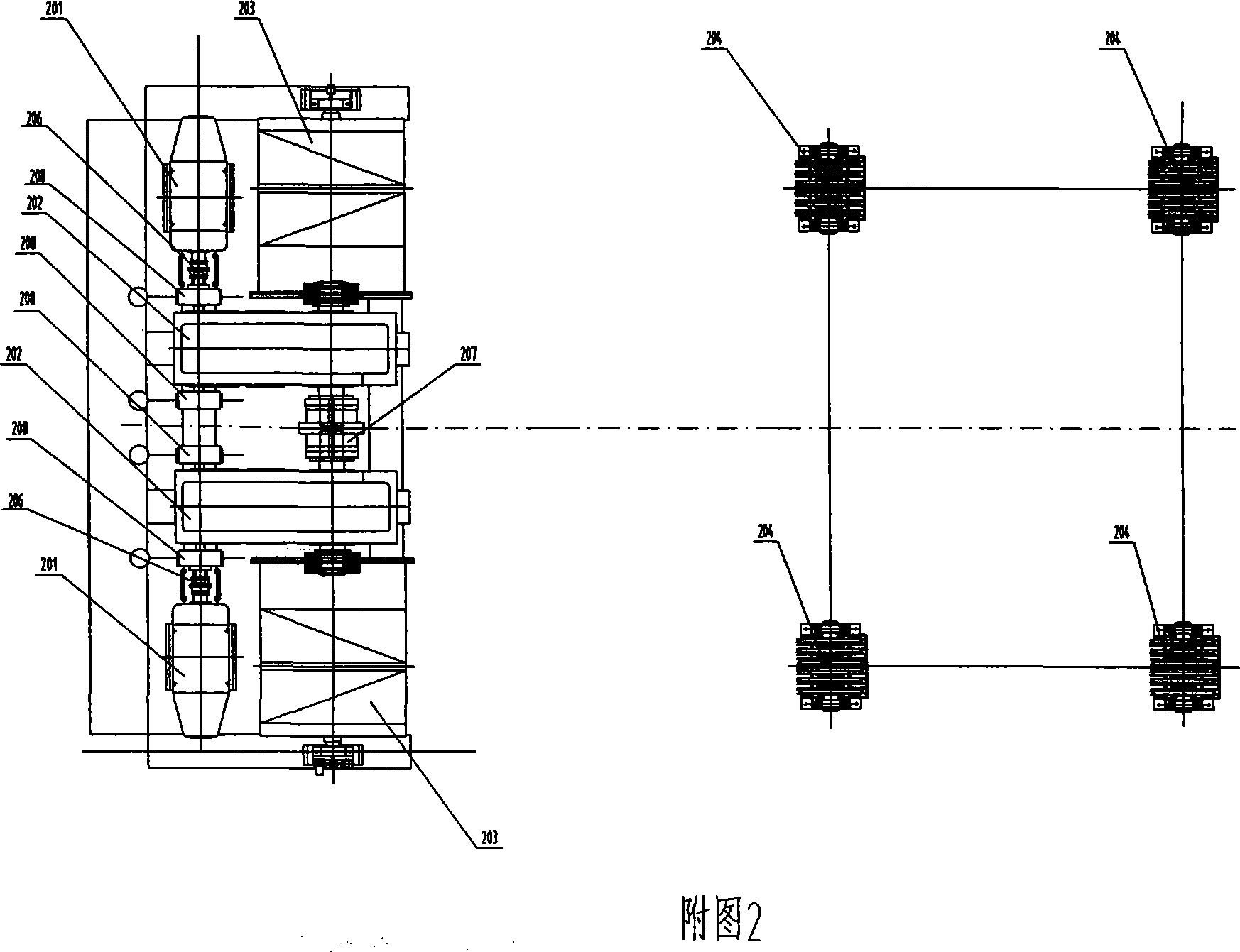

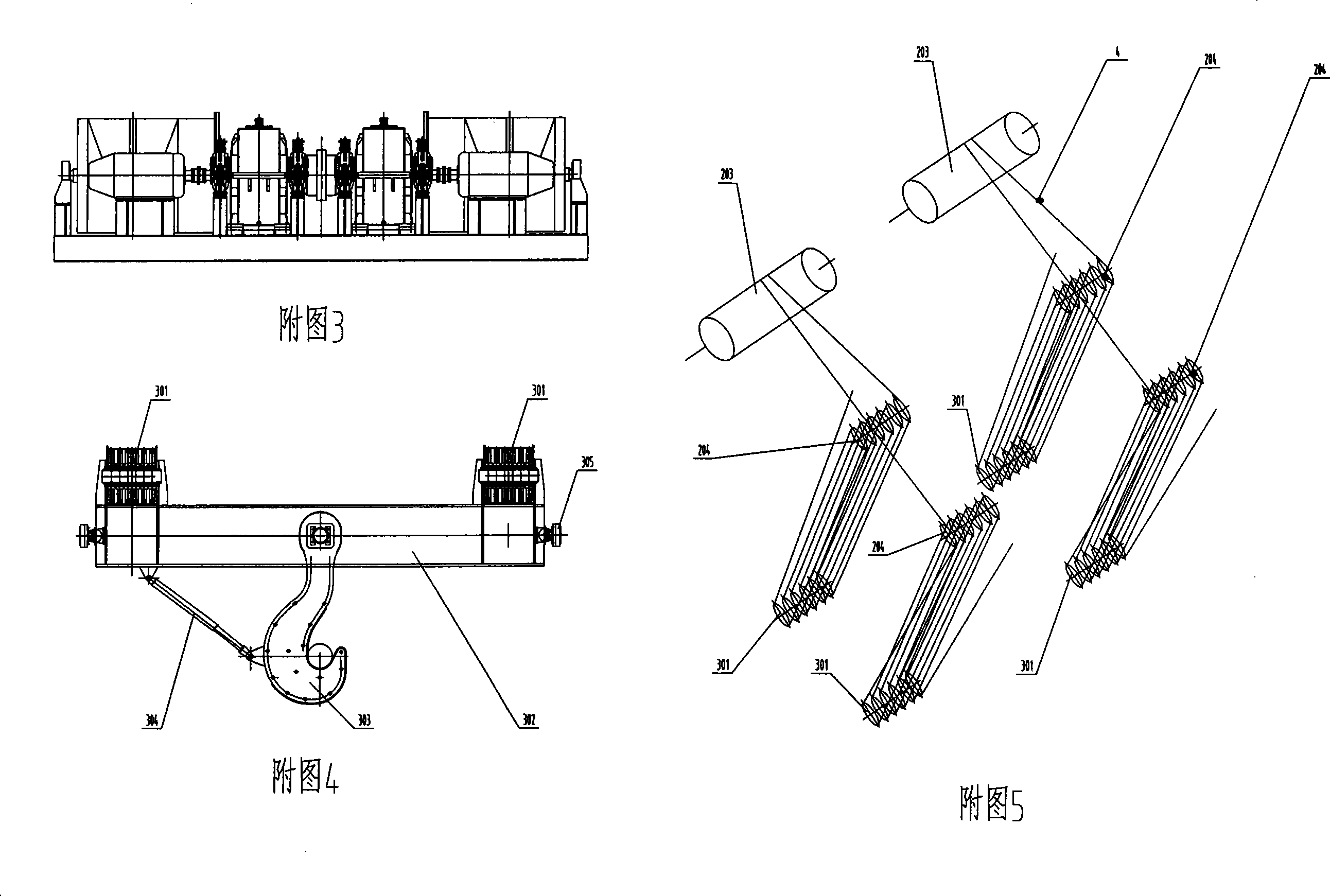

[0018] As shown in Fig. 1, Fig. 2 and Fig. 3, a hoisting and lifting device for a steel ladle is composed of a mechanism platform 1, a hoisting mechanism 2, a winding wire rope 4 and a sling 3. The hoisting mechanism 2 is installed on the mechanism platform 1, and the winding wire rope 4 is connected with the ladle hanger 3 through the reel 203, the fixed pulley block 204, the movable pulley block 301.

[0019] The hoisting mechanism 2 is composed of two motors 201 , a speed reducer 202 , a reel 203 , four fixed pulley blocks 204 , a wire rope fixed end 205 and a brake 208 . The two motors 201 are respectively connected to the input shafts of the two reducers 202 through the two couplings I 206, and the output shafts of the two reducers 202 are connected at one end through the coupling II 207 to realize the mechanical synchronization of the two reels And a single motor works, and the other end drives two drums 203 respectively to realize the lifting and lowering of the ladle. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap