Method for preparing modified asphalt by using waste plastics

A technology of waste plastics and modified asphalt, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of expensive modified asphalt, increased investment in road surface engineering, and high prices, and achieves reduced ruts, low prices, and Effect of improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

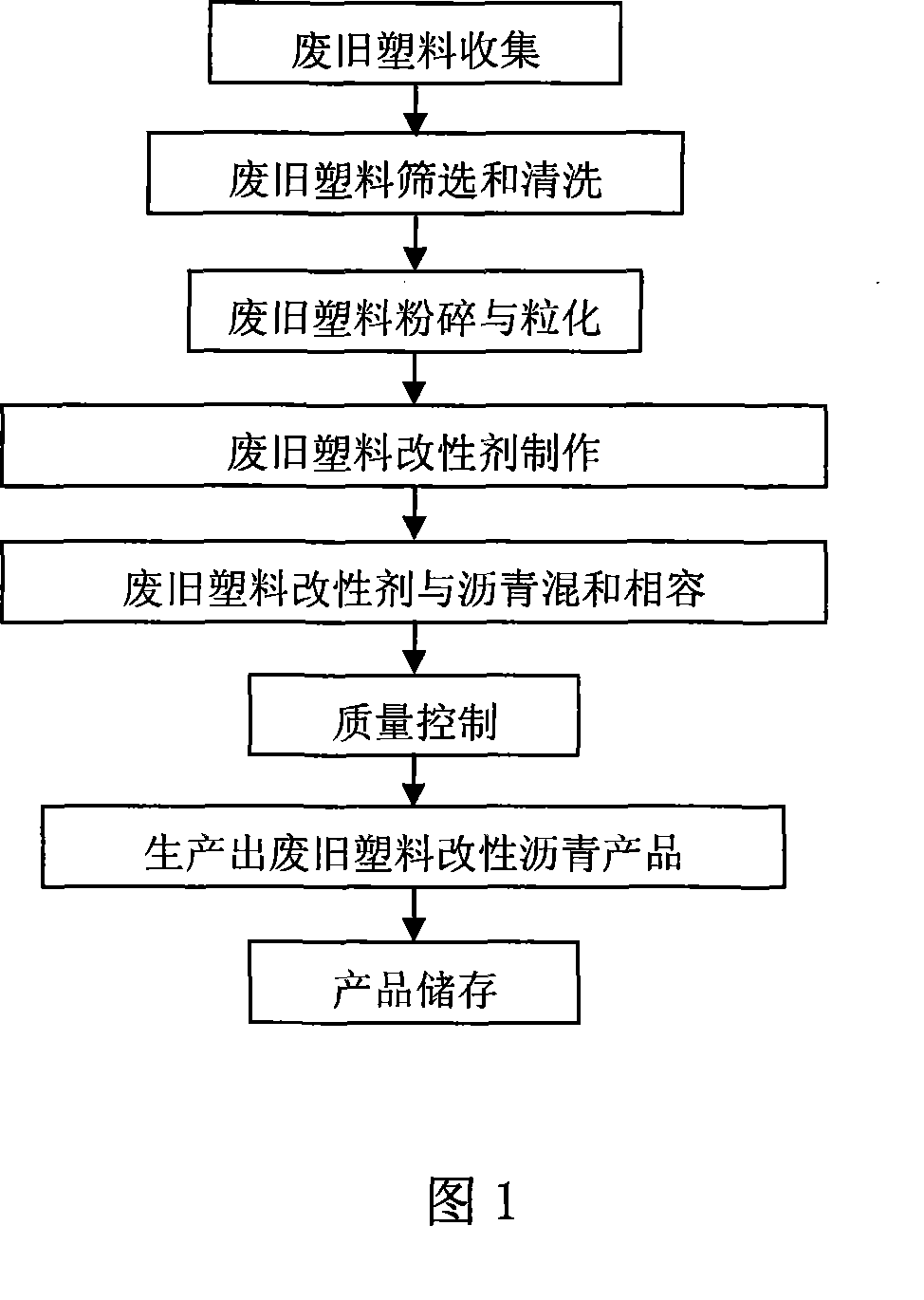

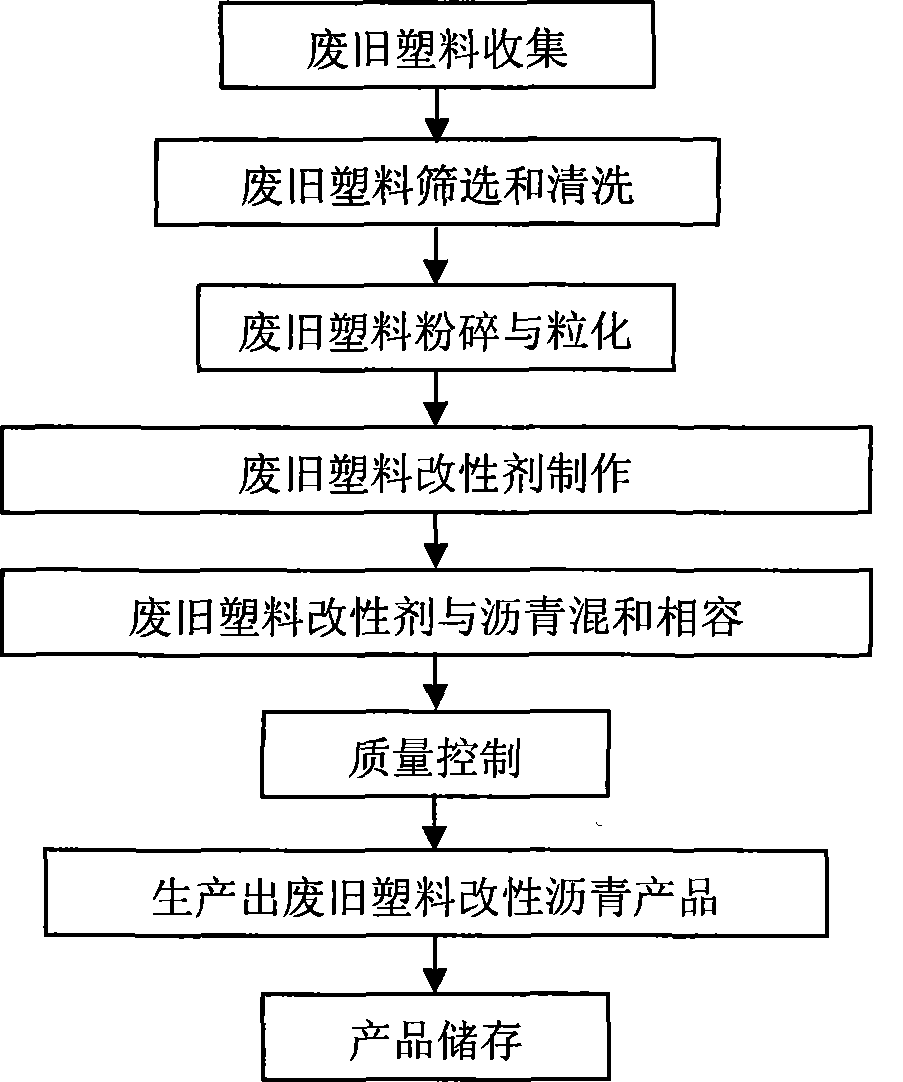

[0021] According to the characteristics of complex components of waste plastics and the technical requirements for the high-temperature stability of asphalt and asphalt mixture on road surfaces, the present invention makes waste plastics into waste plastic modifiers, and then uses the waste plastic modifiers to make waste plastics modified Sexual asphalt.

[0022] A method for making modified asphalt from waste plastics, the technical proposal of which is:

[0023] (1) Collection and crushing of waste plastics: The types of waste plastics collected include plastic films, various household plastic bags, plastic products (plastic barrels, plastic basins, plastic stools), and various woven bags. For the convenience of collection and cleaning, first Sorting and collecting, cleaning after collection, dehydration and crushing;

[0024] (2) Waste plastic granulation: the method is to heat the crushed waste plastic to about 200°C, melt it for 30-45 minutes, cool it, and process it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com