Suction channel of fiber bundle unit

A technology of fiber bundles and channels, applied in the field of fiber bundles, can solve the problems of high cost of use, reduce air consumption, and avoid changes in the direction of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

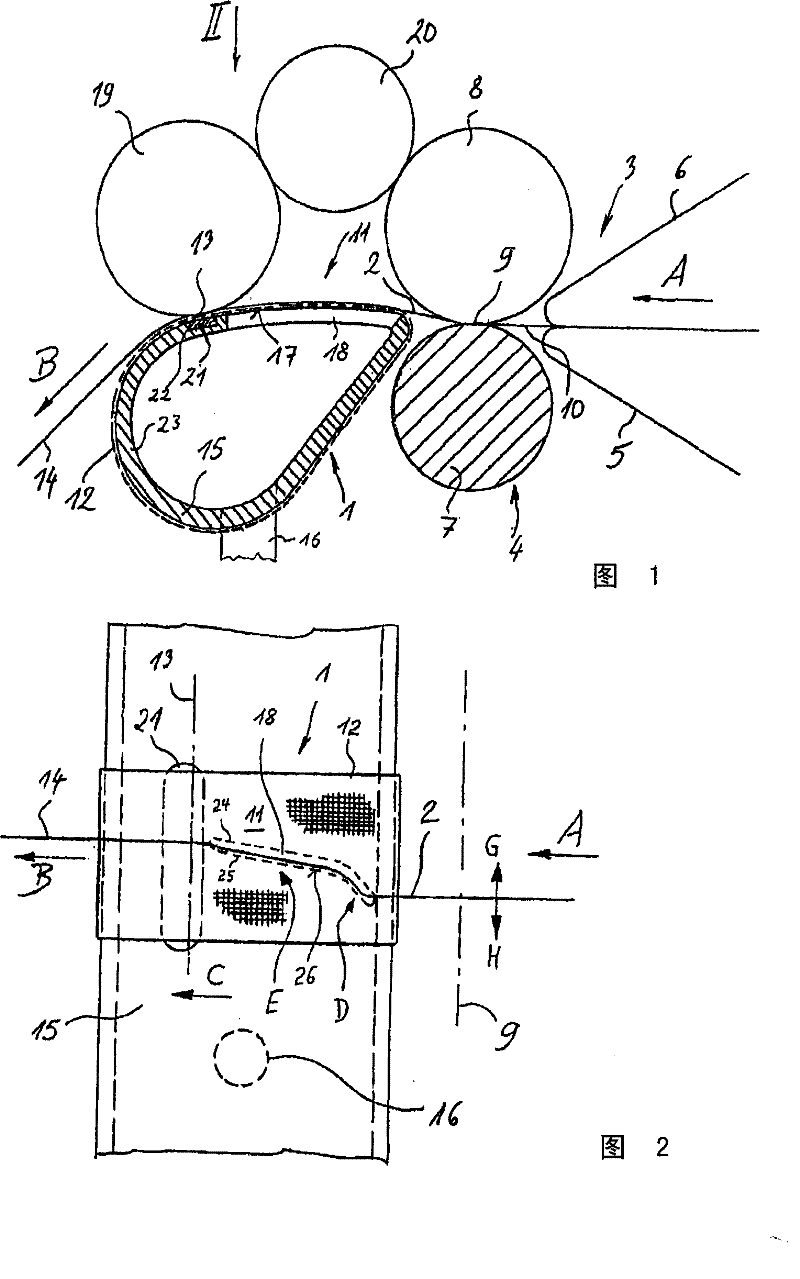

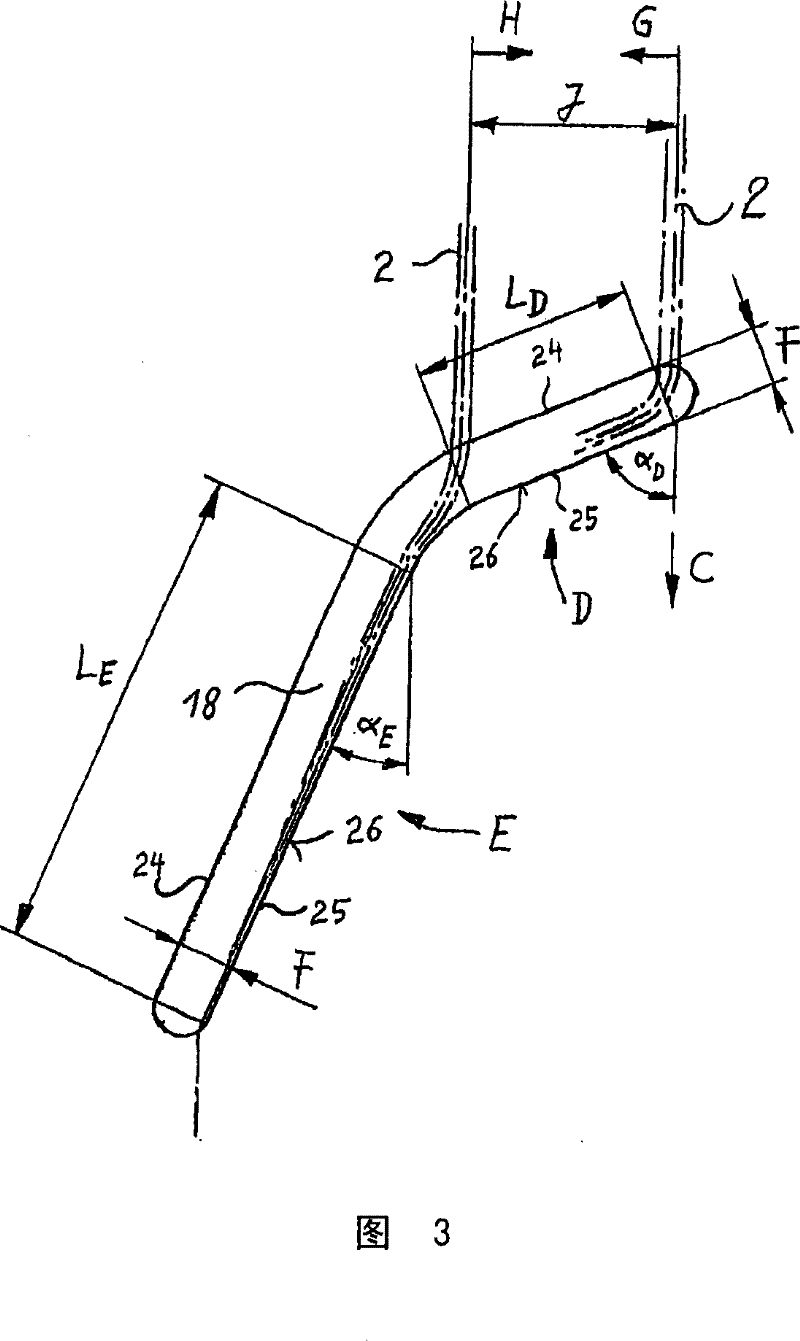

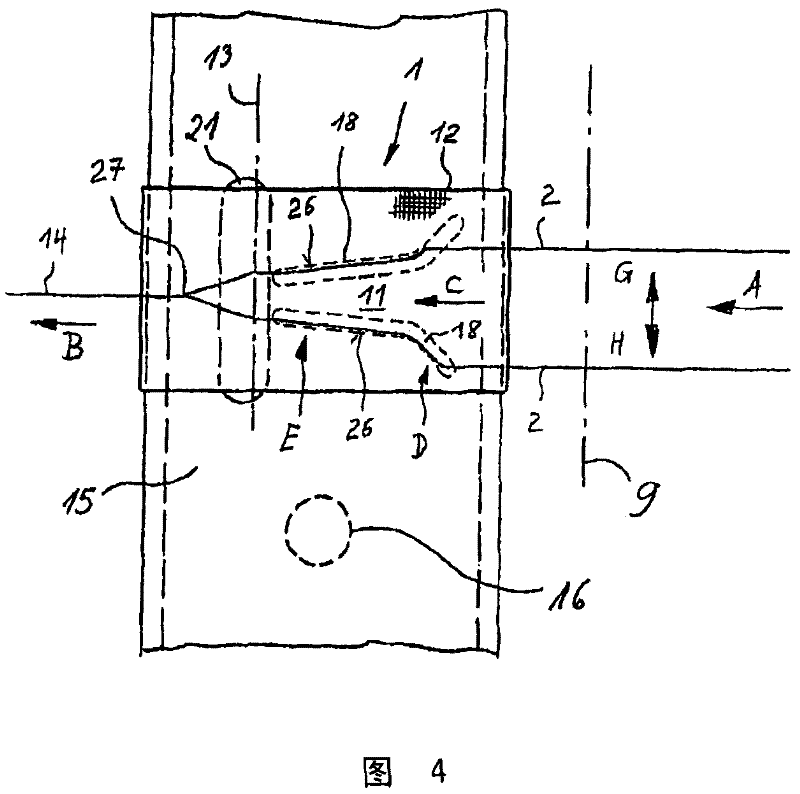

[0020] exist figure 1 and figure 2 A fiber bundle device 1 for compressing a fiber sliver 2 of short fibers is shown in FIG. 2 , which is arranged downstream of a only partly shown drafting unit 3 of a weaving machine. The weaving machine, which can be, for example, a ring spinning machine, usually has a plurality of drafting units 3 arranged side by side. Only the front pair of drafting rollers 4 and the upstream small belt pairs 5, 6 are shown in this drafting mechanism 3, which is designed in a known manner.

[0021] The front drafting roller pair 4 comprises driven bottom rollers 7, which can be configured as bottom rollers passing in the longitudinal direction of the machine, and each drafted fiber sliver is assigned a hold-down roller 8. The bottom roller 7 and the pressure roller 8 together form a front nip line 9 which ends the drafting zone of the drafting mechanism 3 . The fiber web or alternatively the roving 10 is fed to the drafting device 3 along the conveyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com