Suction brake, sheet conveyor with such suction brake and method of applying a retardation force to a moving sheet of material

A technology of brakes and conveyors, which is applied in the direction of sending objects, transportation and packaging, thin material handling, etc., and can solve the problems of reduced binding force, reduced output, and reduced productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

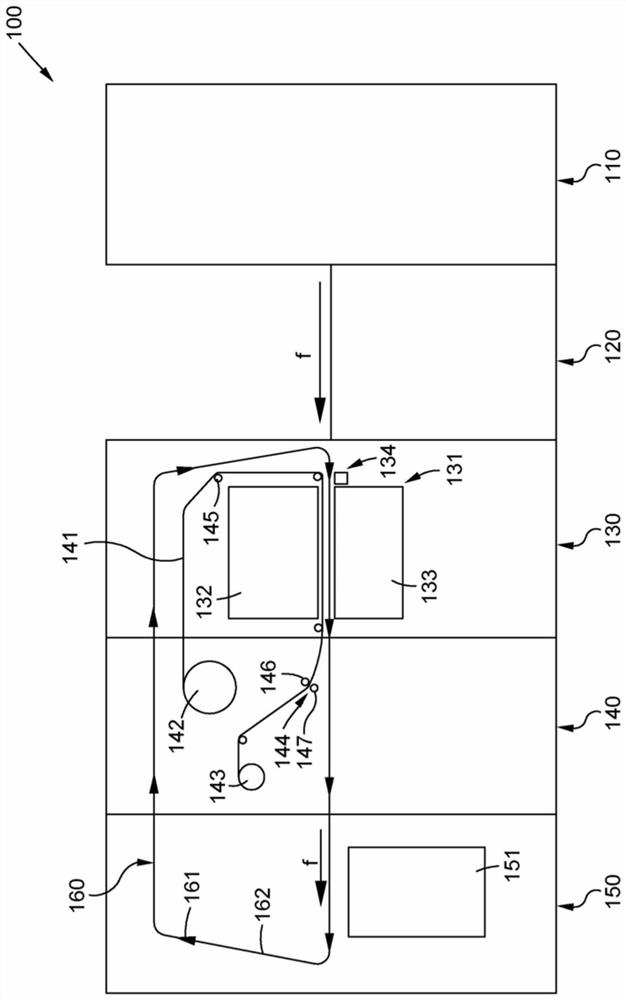

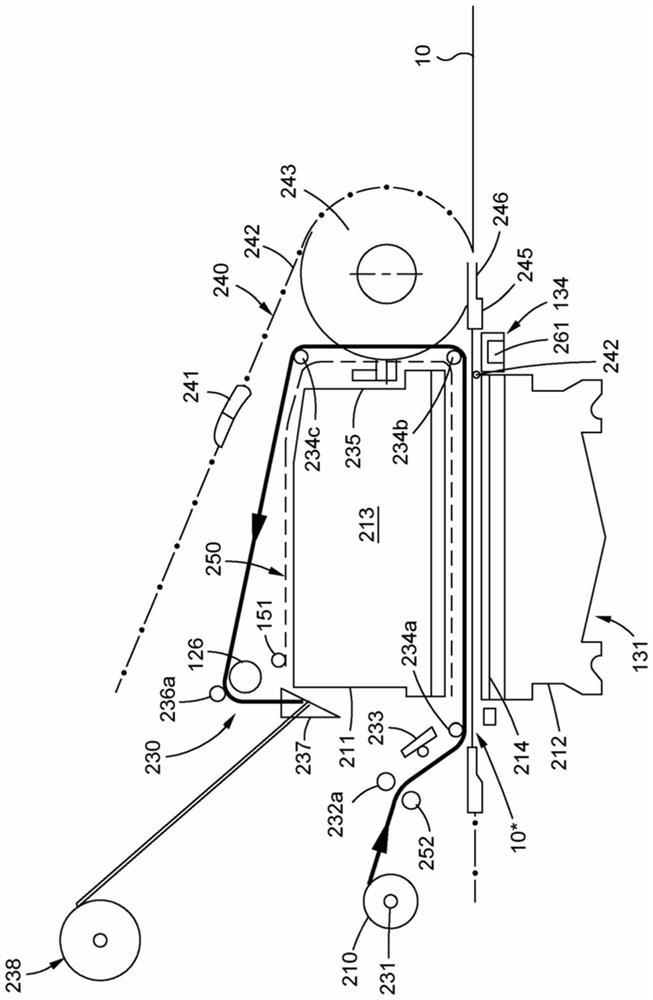

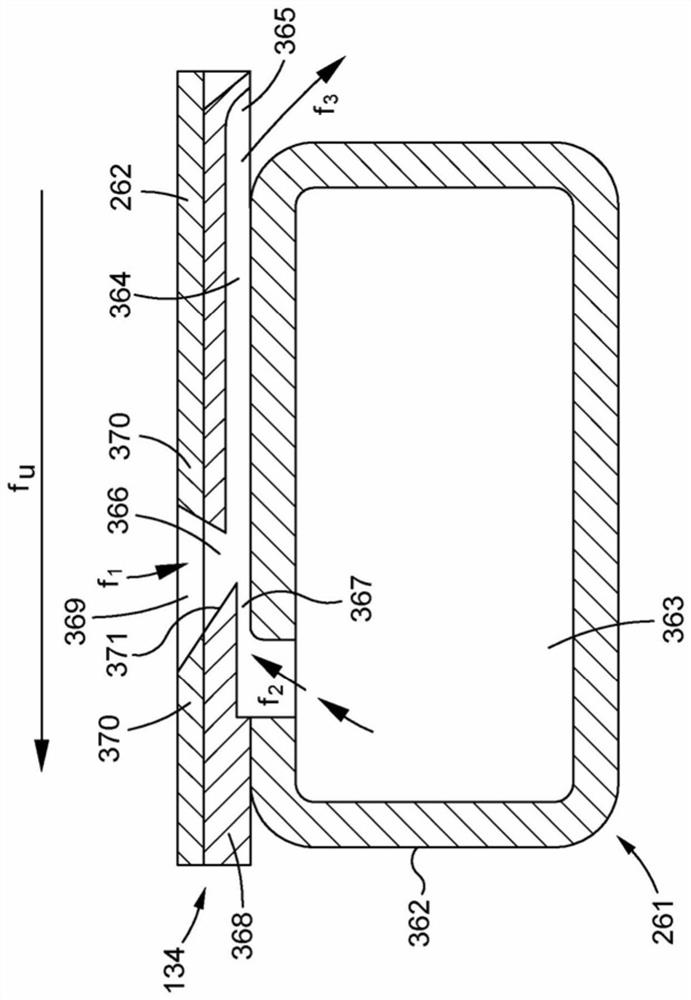

[0034] In order to provide a context for describing embodiments of the present invention, a conventional sheet processing machine, which may be equipped with a suction brake according to an embodiment of the present invention, will first be described. therefore, figure 1 Shown is a sheet converting machine 100 that uses stamping to customize cardboard packaging for the luxury goods industry. Such processing machines are generally called hot stamping machines and are known in the prior art. Therefore, neither its structure nor its operation will be described in detail here. Also, for ease of description and understanding, only one station of the sheet processing machine is described as including a suction brake, but the skilled person will appreciate that more than one station may include a suction brake. Also, of course, although the table described as having a suction brake is a punching table, a suction brake according to an embodiment of the invention may be used on other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com