Variable stiffness elastic support used for a ballastless track

A technology of elastic bearings and ballastless tracks, which is applied in the field of rail transit, can solve problems such as potential safety hazards, poor resistance to repeated impacts, poor fatigue performance, poor vibration isolation capabilities, etc., to achieve convenient installation, limit sideslip and displacement, and ensure The effects of stability and line safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

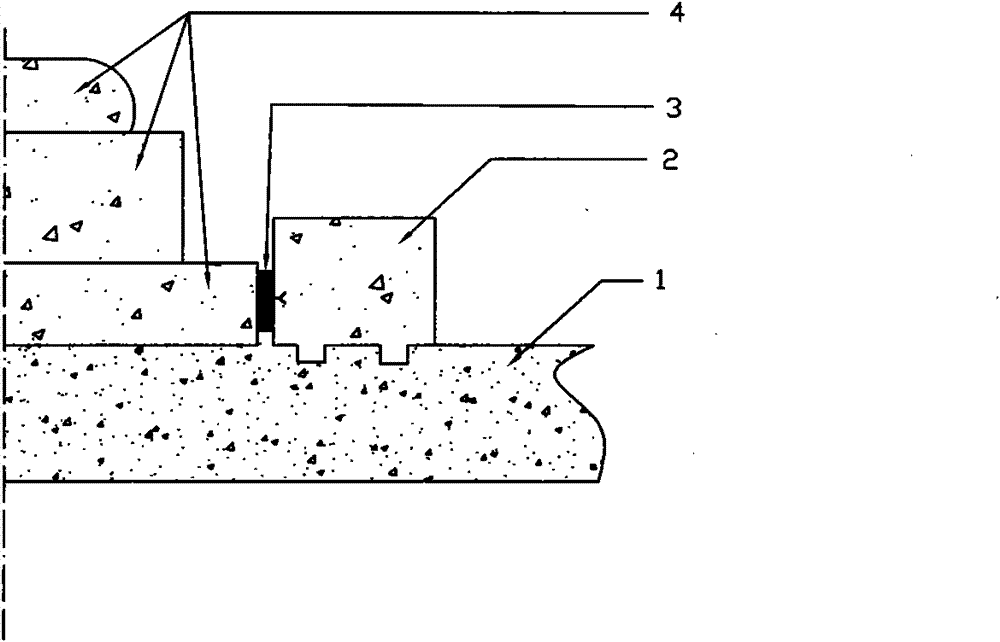

[0012] attached figure 1 , 2 The non-restrictive disclosure discloses a structural schematic diagram and a schematic diagram of use of a specific implementation example involved in the present invention. The protection scope of the present invention is not limited to the situation described in the embodiment. The present invention will be further described below in conjunction with the accompanying drawings.

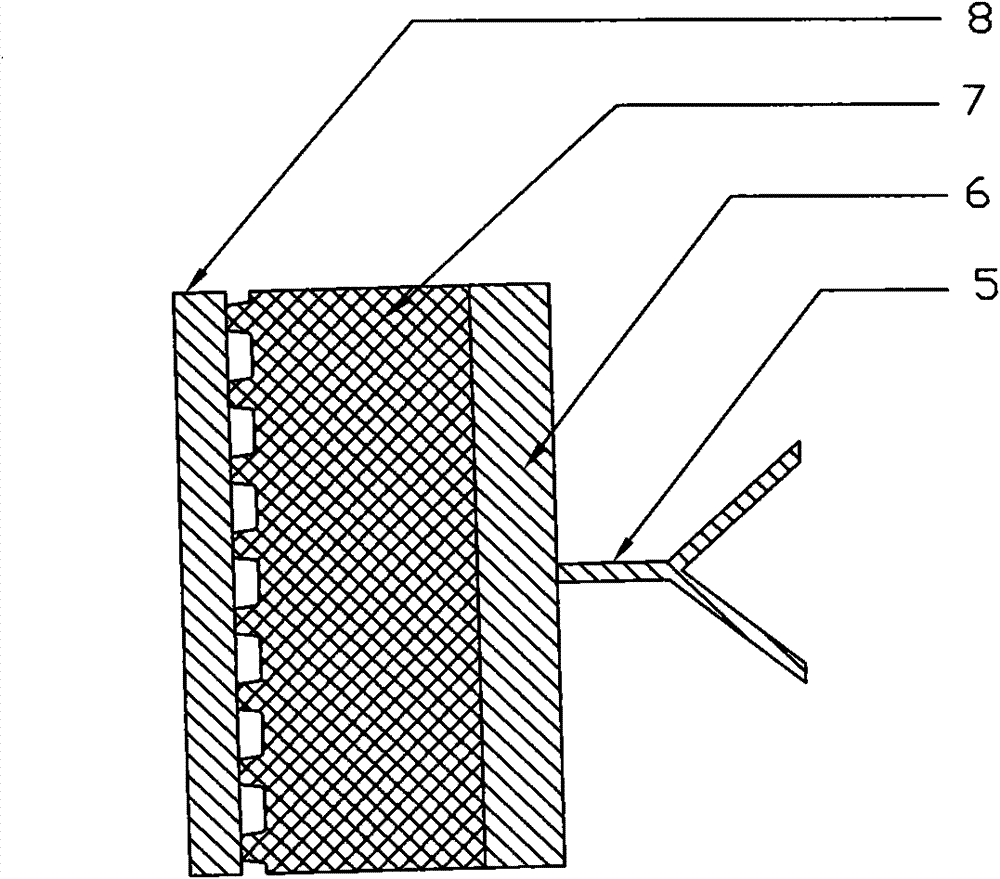

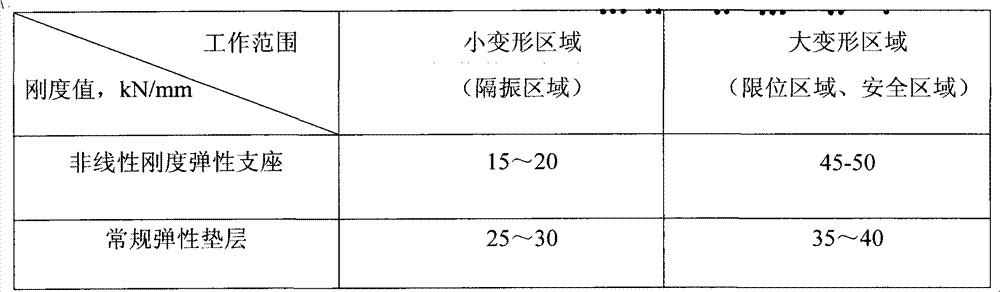

[0013] like figure 1 As shown, when the nonlinear rigidity elastic support 3 involved in the present invention is applied to the CRTS II ballastless track, the installation and fixed positioning are realized by pouring the anchor piece 5 and the lateral block concrete 2 into one body, so that the entire elastic The support is fixed on the above-mentioned concrete structure; the base plate 6 is bordered by the block concrete 2, and the panel 8 is bordered by the track structure 4, and the panel is a flat plate with a flat structure, which is in contact with the track str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com