Alkaline dry battery

A dry battery and alkaline technology, which is applied in the field of alkaline dry batteries, can solve the problems of large production quantity and high cost of dry batteries, and achieve the effect of maintaining balanced battery characteristics, high reliability, and excellent anti-leakage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051]

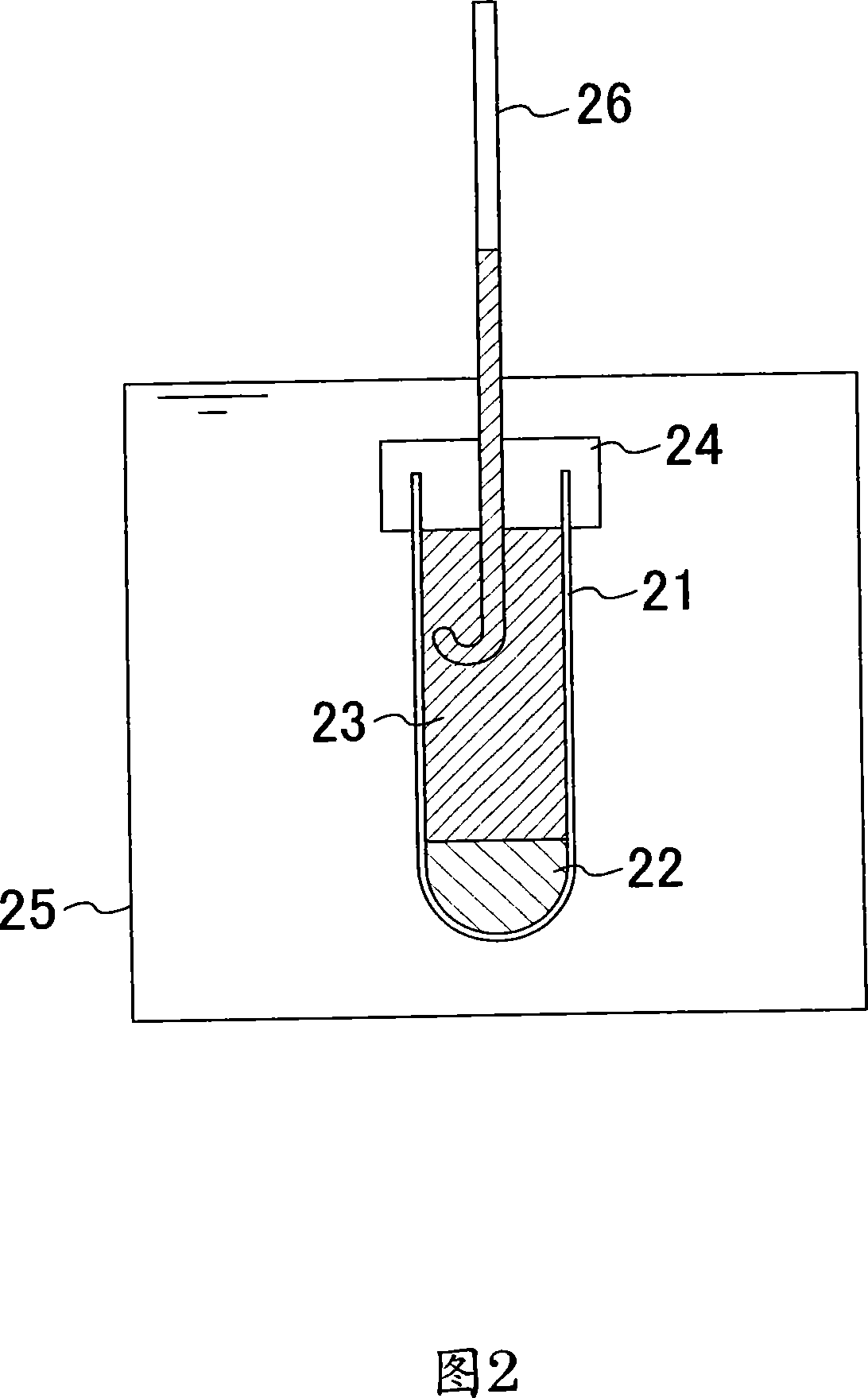

[0052] First, a preliminary experiment was carried out in order to grasp the degree of corrosive gas generation from zinc alloy powder with a small indium content.

[0053] The zinc metal material with a purity of more than 99.99% is melted at a temperature exceeding 500°C. Thereafter, various elements were added so that the ratios of the contained elements were in the state shown in Table 1, and the zinc metal material and the various elements were melted into a uniform state to obtain a zinc alloy solution. Thereafter, the molten zinc alloy was sprayed (atomized) with a high-pressure gas to be pulverized to obtain zinc alloy powder. Use a sieve to adjust the obtained zinc alloy powder into two particle sizes as the negative electrode active material. The two particle sizes are: (1) 35 mesh to 300 mesh (the proportion of fine powder below 75 μm is 25%), and (2) 35 mesh to 200 mesh (the proportion of fine powder below 75μm is 5%). In addition, the content of indiu...

no. 1 example

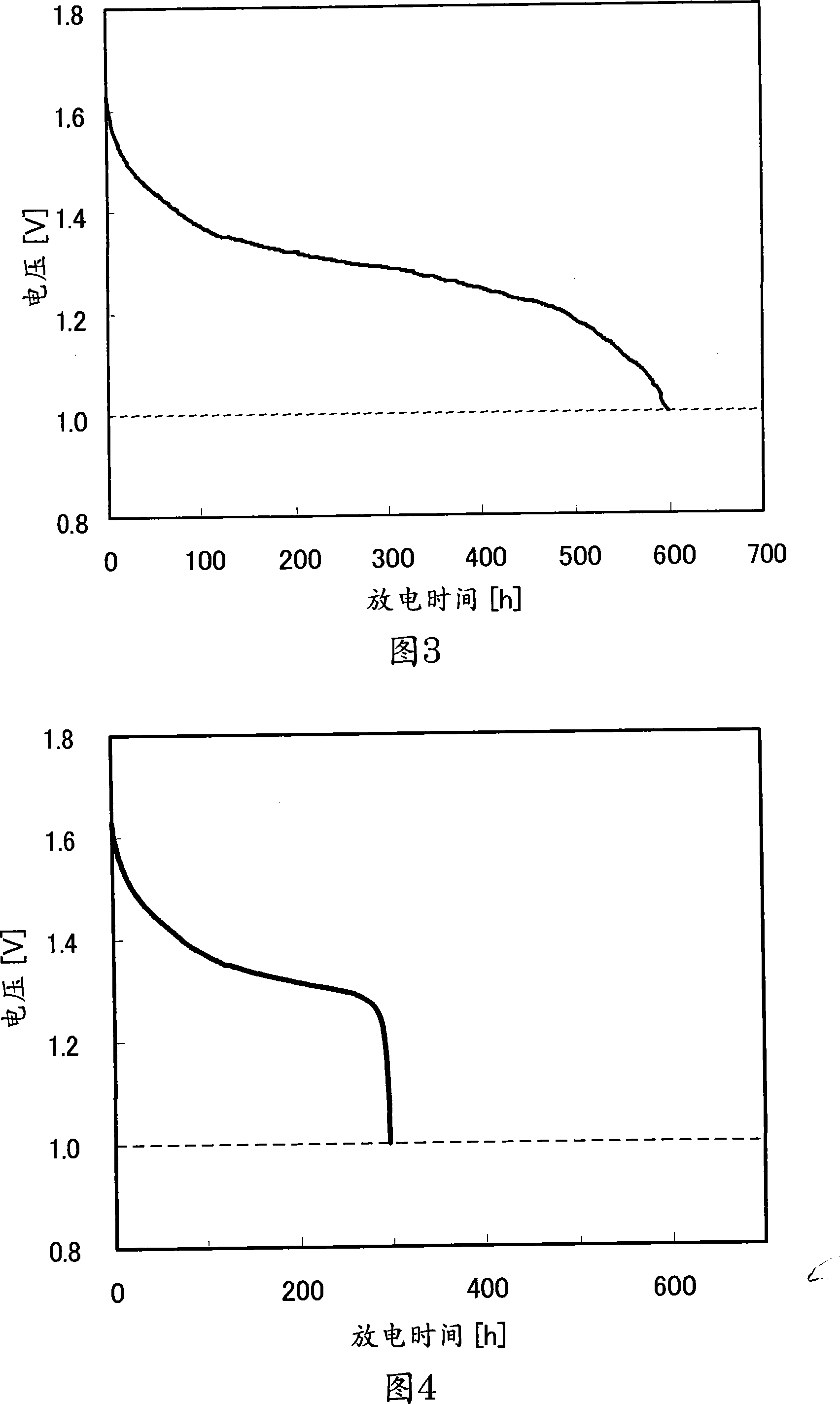

[0067] Based on the results of the above-mentioned preliminary experiments, batteries produced by changing the contents of aluminum and indium in the zinc alloy powder to various contents were evaluated.

[0068] The zinc metal material with a purity of more than 99.99% is melted at a temperature exceeding 500°C. Thereafter, various elements were added so that the ratios of the contained elements were as shown in Table 3. Thereafter, the zinc metal material and various elements were melted into a uniform state to obtain a zinc alloy solution. Thereafter, the molten zinc alloy was sprayed (atomized) with a high-pressure gas to be pulverized to obtain zinc alloy powder. The obtained zinc alloy powder was adjusted to 35 mesh to 300 mesh (25% of the fine powder ratio of 75 μm or less) with a sieve and used as negative electrode active materials a to r.

[0069] [table 3]

[0070]

type

Content of added elements in zinc alloy [weight percent]

aluminum ...

no. 2 example

[0107] Next, a more detailed study was conducted on the thickness, number of sheets, and number of times of winding of the nonwoven separator.

[0108] To the same gelled electrolyte solution as the gelled electrolyte solution adopted in the first embodiment, a negative electrode active material t (aluminum: weight percentage of 0.020%, bismuth: 0.015% by weight, indium: 0.0001% by weight), and then fully mixed to prepare a gel-like negative electrode T. A positive electrode mixture pellet exactly the same as in the first example was prepared as a positive electrode.

[0109] Five kinds of vinylon-greencell composite non-woven fabrics were prepared as separators, and the thicknesses of each of the five kinds of vinylon-greencell composite non-woven fabrics were different, respectively (1) 120 μm, (2) 150 μm , (3) 180 μm, (4) 200 μm and (5) 220 μm. When inserting the separator and the insulating cap into the positive electrode mixture pellet, the size of the separator was adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com