Truck comprising a rope-operated tilting device for the cab

A technology of a truck and a tilting device, which is applied to the superstructure of trucks, trucks, vehicle parts, etc., can solve the problems of cab damage, driver injury, inability to keep the cab on the chassis, etc., and achieve great freedom The effect of small space and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

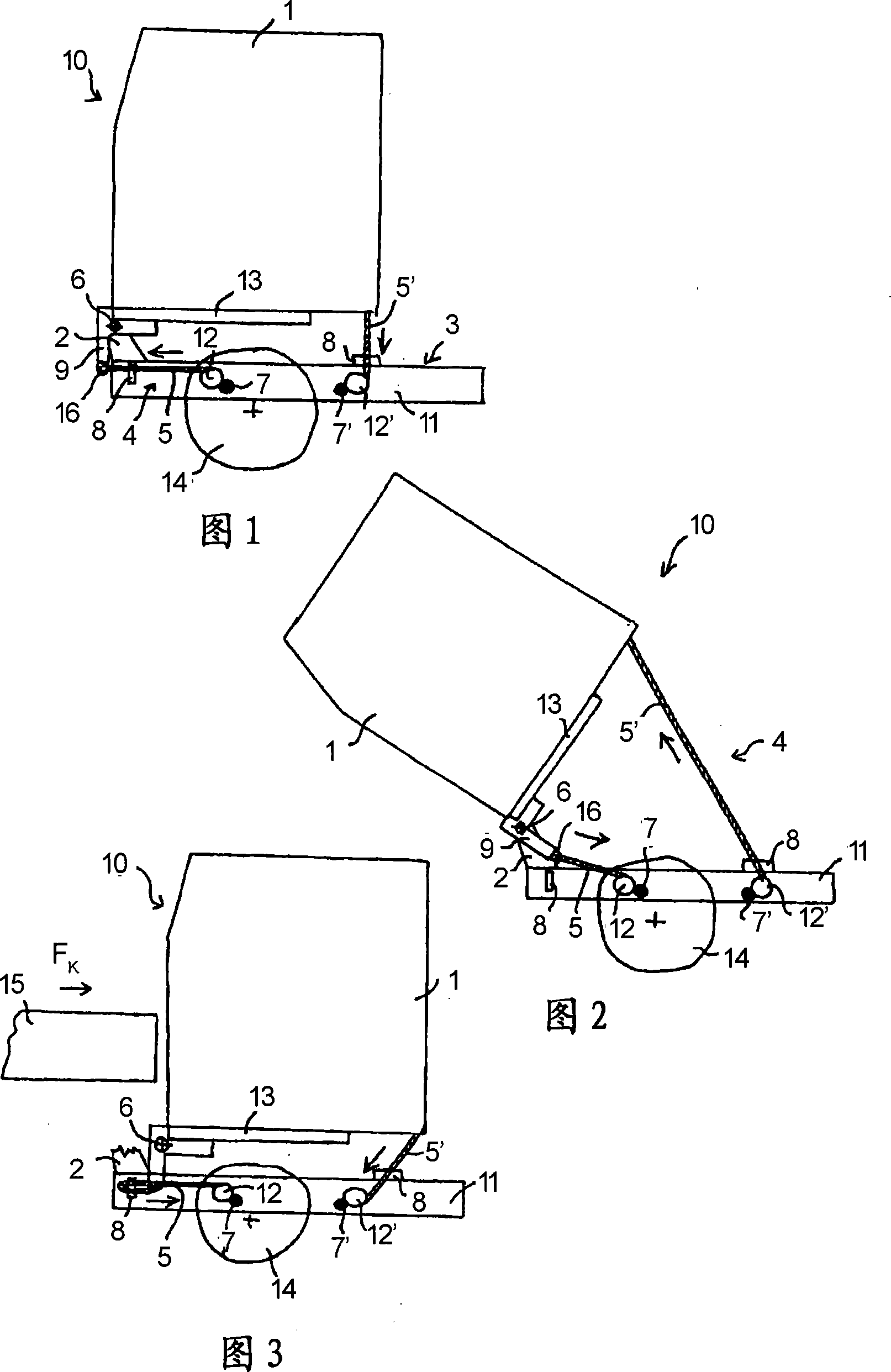

[0023] FIG. 1 shows a schematic side view of an exemplary embodiment of a truck 10 according to the invention with a driver's cab 1 in a closed position for normal driving operation. A tilting device 4 is arranged between the driver's cab 1 and the chassis 3 , by means of which the driver's cab 1 can be tilted upwards about the axis of rotation 6 of the bearing structure 2 . To this end, the driver's cab 1 is articulated at the front end to a support structure 2 in the form of an upwardly protruding bearing block, which is itself fixedly fastened to a longitudinal beam 11 of the chassis 3 . The driver's cab 1 is reinforced at its lower end by side longitudinal beams 13 . In addition to the conventional connection of the driver's cab 1 via the supporting structure 2, a tilting device 4 according to the invention is provided, which consists of a front cable 5 and a rear cable 5', which can be passed through a cable drum in each case. 12, 12' actuation. The rope drums 12, 12' a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com