Drum type drying and washing machine

A washing and drying machine, drum-type technology, applied to other washing machines, washing machines with containers, household clothes dryers, etc., can solve the problems such as the air supply capacity of the blower 31 drops, and achieve the effect of removing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

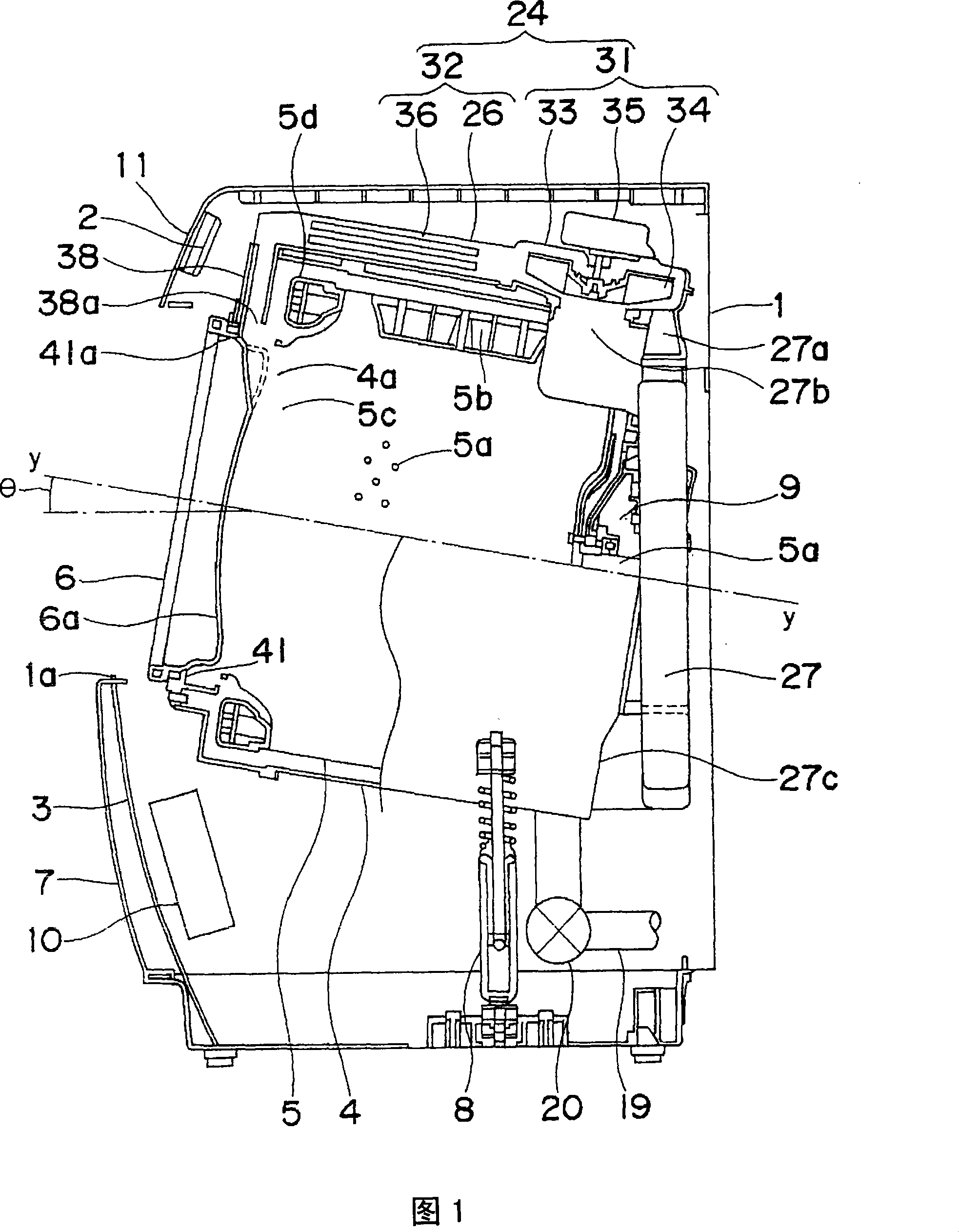

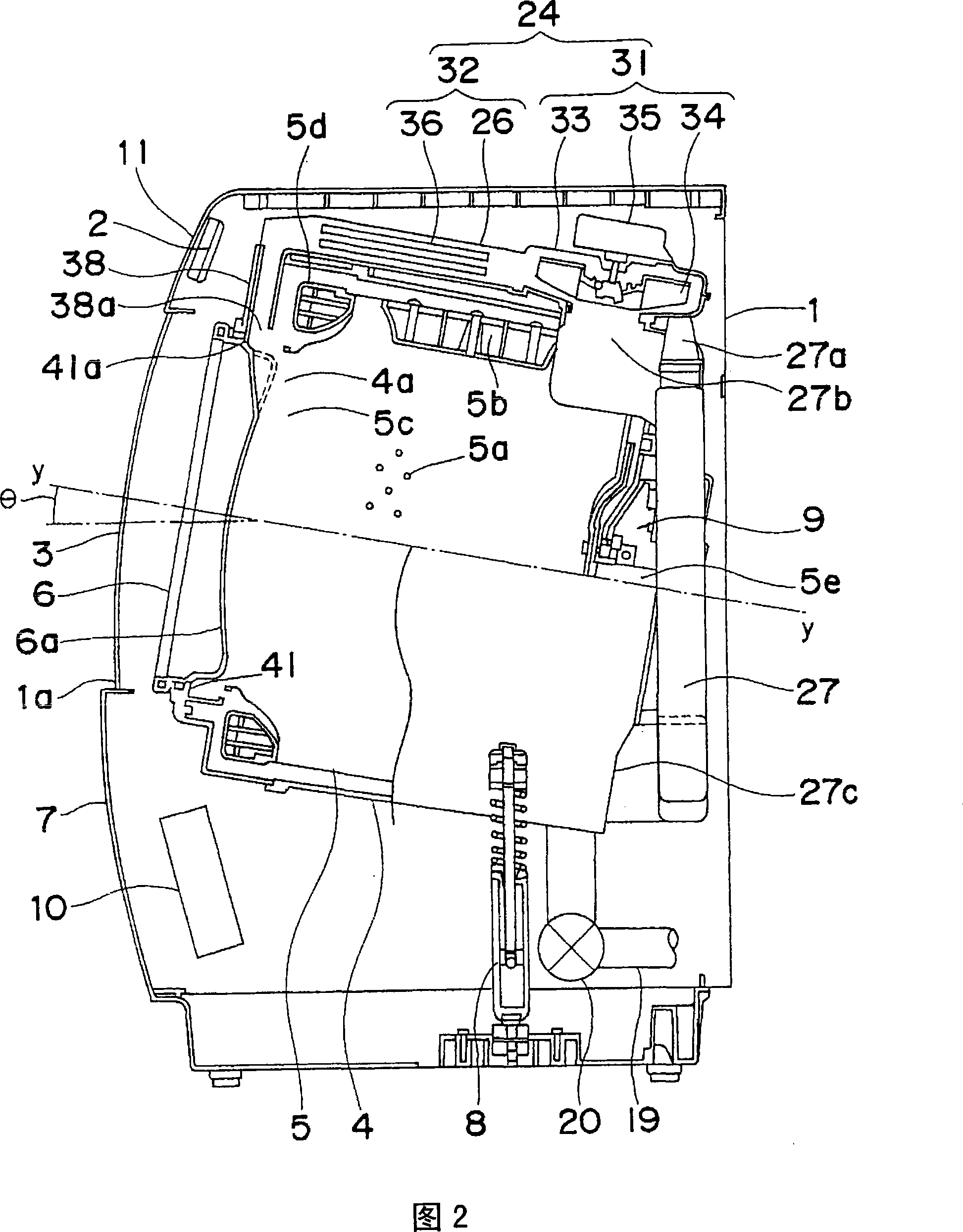

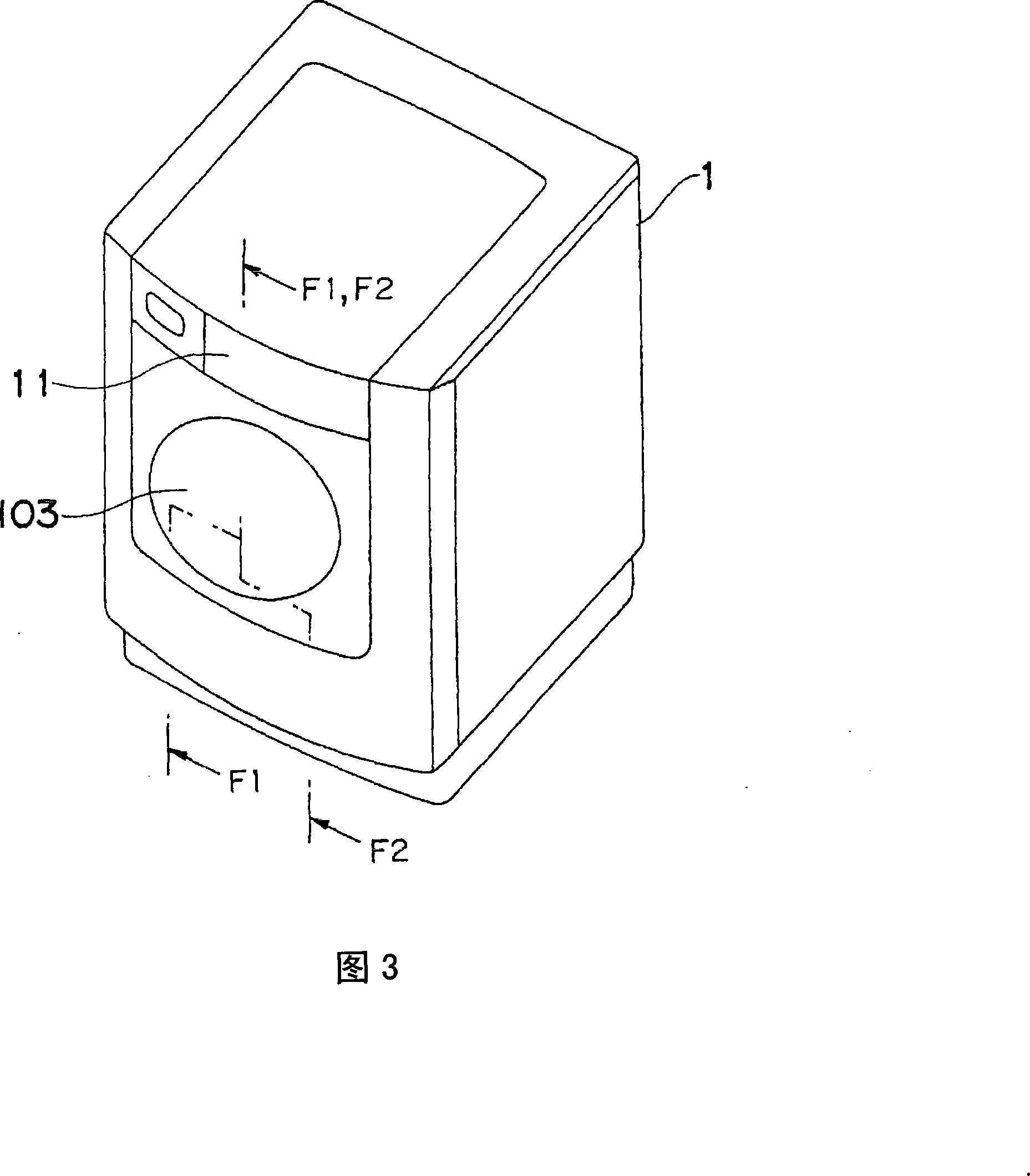

[0144] Fig. 3 is an external perspective view of the drum-type washing and drying machine according to the first embodiment of the present invention. While covering the outer periphery with the outer case 1, this drum type washing and drying machine has an outer case opening 111 (see FIG. The mechanism is rotatably mounted on the outer case 1 . In addition, reference numeral 11 in FIG. 3 is an operation panel.

[0145] FIG. 4 shows a schematic sectional view viewed from line F1 - F1 in FIG. 3 .

[0146] An outer case opening 111 is formed on the front surface of the outer case 1 . The outer case opening 111 is opened and closed by the door 103 that is rotatable relative to the outer case 1 as described above. In addition, the operation panel 11 having operation keys and a display portion is provided on the front upper portion of the outer case 1 . On the back side of the operation panel 11 (on the side of the water tank 4 ), the control unit 2 for controlling the operation...

no. 2 approach

[0190] Fig. 13 is an external perspective view of a drum-type washing and drying machine X according to a second embodiment of the present invention. This drum type washing and drying machine X covers the outer periphery with the outer case 1, and has an outer case opening 111 (refer to FIG. The hinge mechanism is rotatably installed on the outer case 1 . In addition, reference numeral 11 in FIG. 3 is an operation panel.

[0191] FIG. 14 shows a schematic cross-sectional view viewed from line F2-F2 in FIG. 13 .

[0192] An outer case opening 111 is formed on the front surface of the outer case 1 . The outer case opening 111 is opened and closed by the door 103 that is rotatable relative to the outer case 1 as described above. In addition, the operation panel 11 having operation keys and a display portion is provided on the front upper portion of the outer case 1 . On the back side of the operation panel 11 (on the side of the water tank 4 ), a control unit 202 for controll...

no. 3 approach

[0269] Fig. 27 is an external perspective view of a drum-type washing and drying machine X according to a third embodiment of the present invention. This drum type washing and drying machine X covers the outer periphery with the outer case 1, and has an outer case opening 111 (refer to FIG. The hinge mechanism is rotatably installed on the outer case 1 . In addition, reference numeral 11 in FIG. 27 is an operation panel.

[0270] FIG. 28 shows a schematic cross-sectional view viewed from line F1 - F1 in FIG. 27 .

[0271] An outer case opening 111 is formed on the front surface of the outer case 1 . The outer case opening 111 is opened and closed by the door 103 that is rotatable relative to the outer case 1 as described above. In addition, the operation panel 11 having operation keys and a display portion is provided on the front upper portion of the outer case 1 . On the back side of the operation panel 11 (on the side of the water tank 4 ), a control unit 2 for controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com