Rail clip of toy galloping car

A flying car and toy technology, applied in the field of toy cars, can solve the problems of affecting the racing effect, flying out of the track, reducing the fun of playing, etc., to achieve the effect of improving the speed of the racing car and the viewing effect, stabilizing the track, and improving the fun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

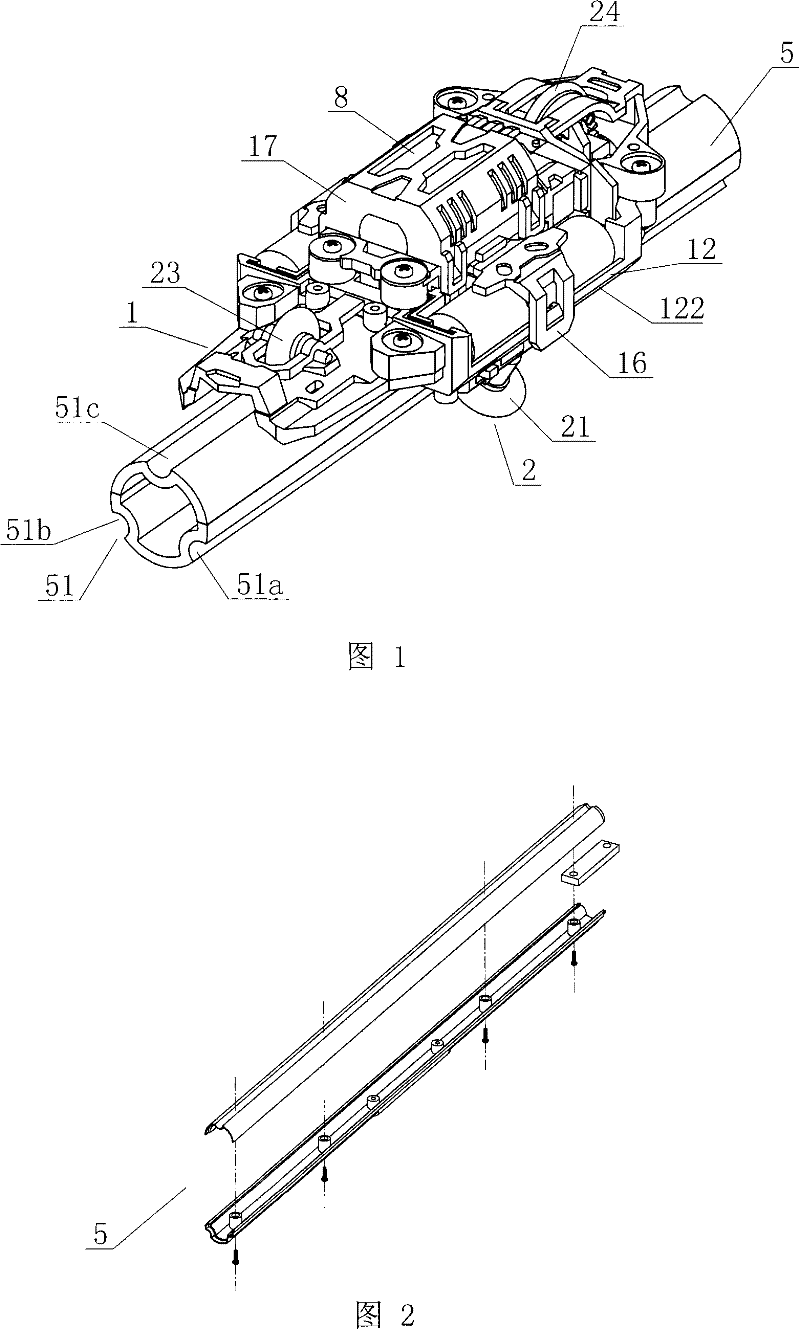

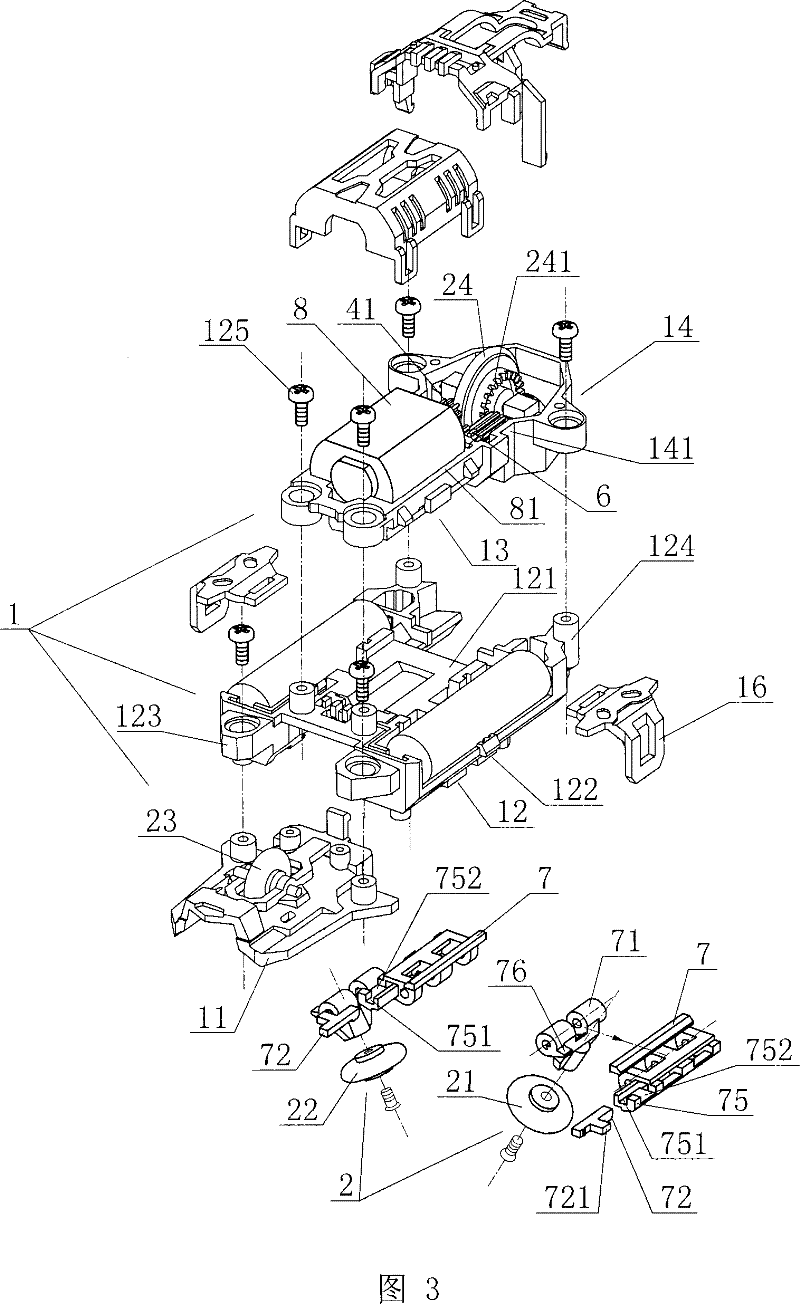

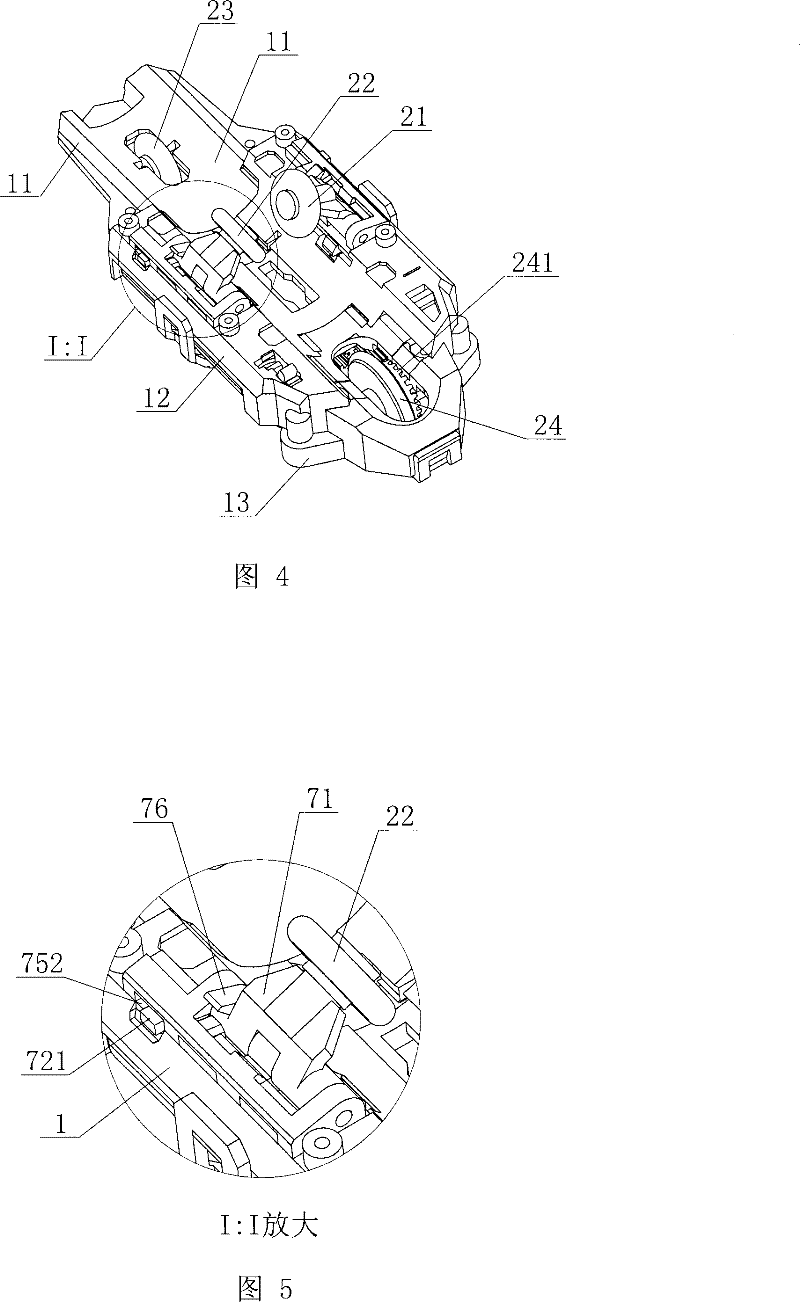

[0028] Embodiment one: if figure 1 , 6 , shown in 10, the grab wheel of the present invention includes the wheel rails that are arranged on both sides of the chassis 1 bottom two sides respectively to grab the wheel rails that are provided with and travel along the wheel rails. Guide wheel comprises the auxiliary guide wheel 23 that is arranged on the middle front of chassis 1 bottom and is arranged on chassis 1 rear and the power wheel 24 that travels along the same track line with auxiliary guide wheel 23. The wheel rails include two groove rails 51a, 51b symmetrically arranged on both sides of the track 5 for the left and right rows of locking wheels to lock and run and a groove rail 51c arranged in the middle of the upper part of the track 5 for the guide wheels to run. The clamping wheels 21, 22 of the toy rail car of this example are locked in the groove rails 51a, 51b of the track 5 and travel along the groove rails 51a, 51b, and the power guide wheel 24 and the auxili...

Embodiment 2

[0029] Embodiment two: if Figure 11 , 12 As shown, the holding wheel of the present invention includes two holding wheels 21 and 22 symmetrically arranged on both sides of the bottom of the chassis 1 respectively holding the wheel rails provided on both sides of the toy car track 5 and traveling along the wheel rails. The guide wheels include an auxiliary guide wheel 29a and a power wheel 29b which are respectively arranged at the front and rear ends of the bottom of the chassis 1 and can run on the surface of the track 5. The rim surfaces of the auxiliary guide wheel 29a and the power wheel 29b are arranged as grooves matching the track surface . The wheel rails include two groove rails 51a, 51b symmetrically arranged on both sides of the track 5 for the left and right rows of locking wheels to hold and drive. The locking wheels 21, 22 provided on both sides of the lower part of the toy rail car in this example are locked in the groove rails 51a, 51b of the track 5 and run...

Embodiment 3

[0030] Embodiment three: as Figure 13 , 14 As shown, the holding wheel of the present invention includes two holding wheels 21, 22 symmetrically arranged on both sides behind the bottom of the chassis 1, respectively holding the wheel rails provided on both sides of the toy car track 5 and traveling along the wheel rails. The guide wheels include the auxiliary guide wheels 25, 26 which are arranged on the front sides of the bottom of the chassis 1 and are respectively in line with the rear locking wheels and run on the same track line. The rim surfaces of the locking wheels 21, 22 and the auxiliary guide wheels 25, 26 are arranged as grooves matching the track surfaces. The holding wheels 21, 22 and auxiliary guide wheels 25, 26 hold the wheel rails through grooves and travel on the wheel rails. The wheel rails include two groove rails 51a, 51b symmetrically arranged on both sides of the track 5 for the left and right rows of locking wheels to hold and drive. In this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com