Welding flux for electroslag surfacing

A technology of electroslag surfacing and flux, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problems of molten pool flow, inability to carry out surfacing welding of deposited metal thickness, etc., to prevent the deterioration of slag peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

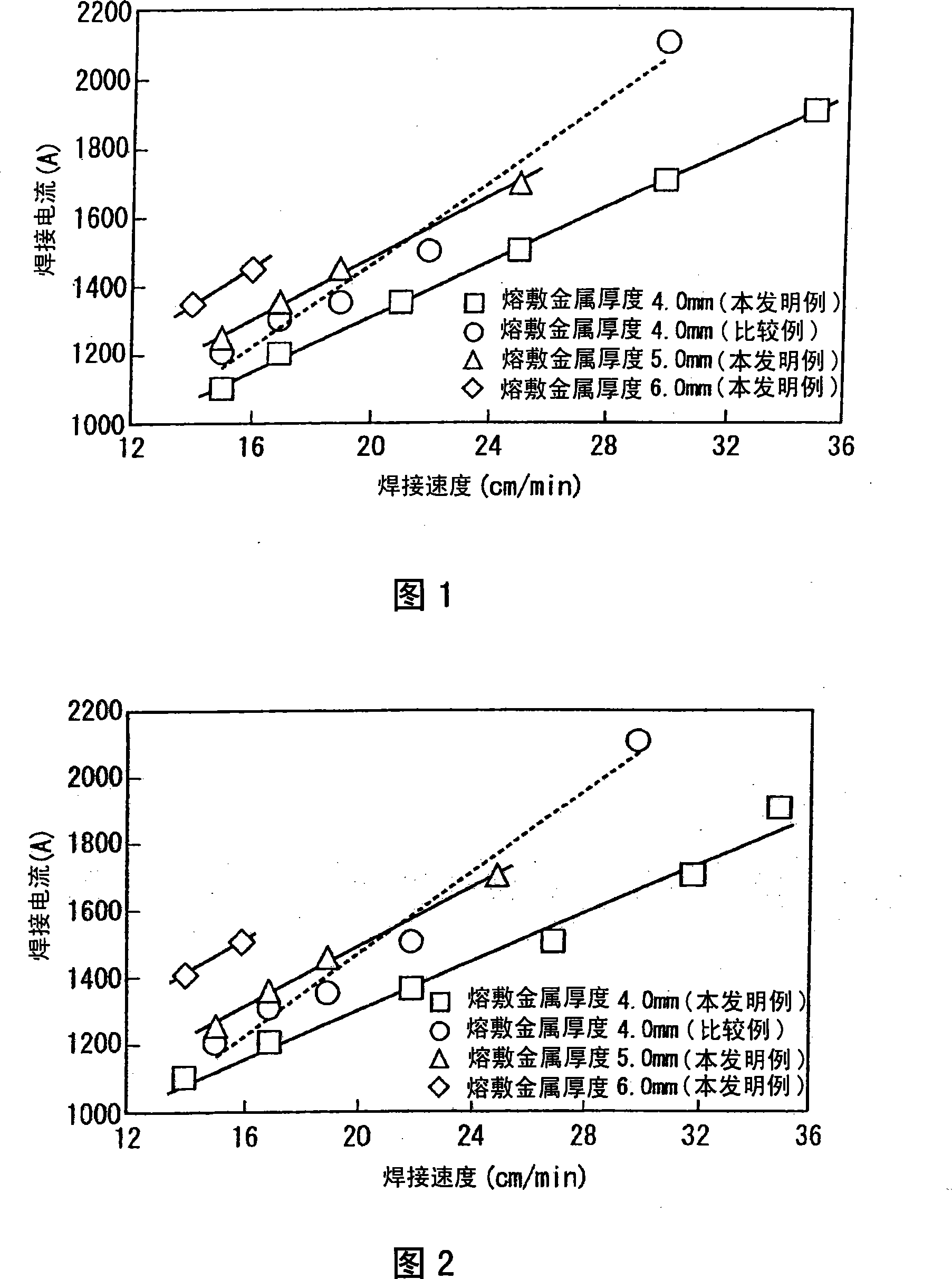

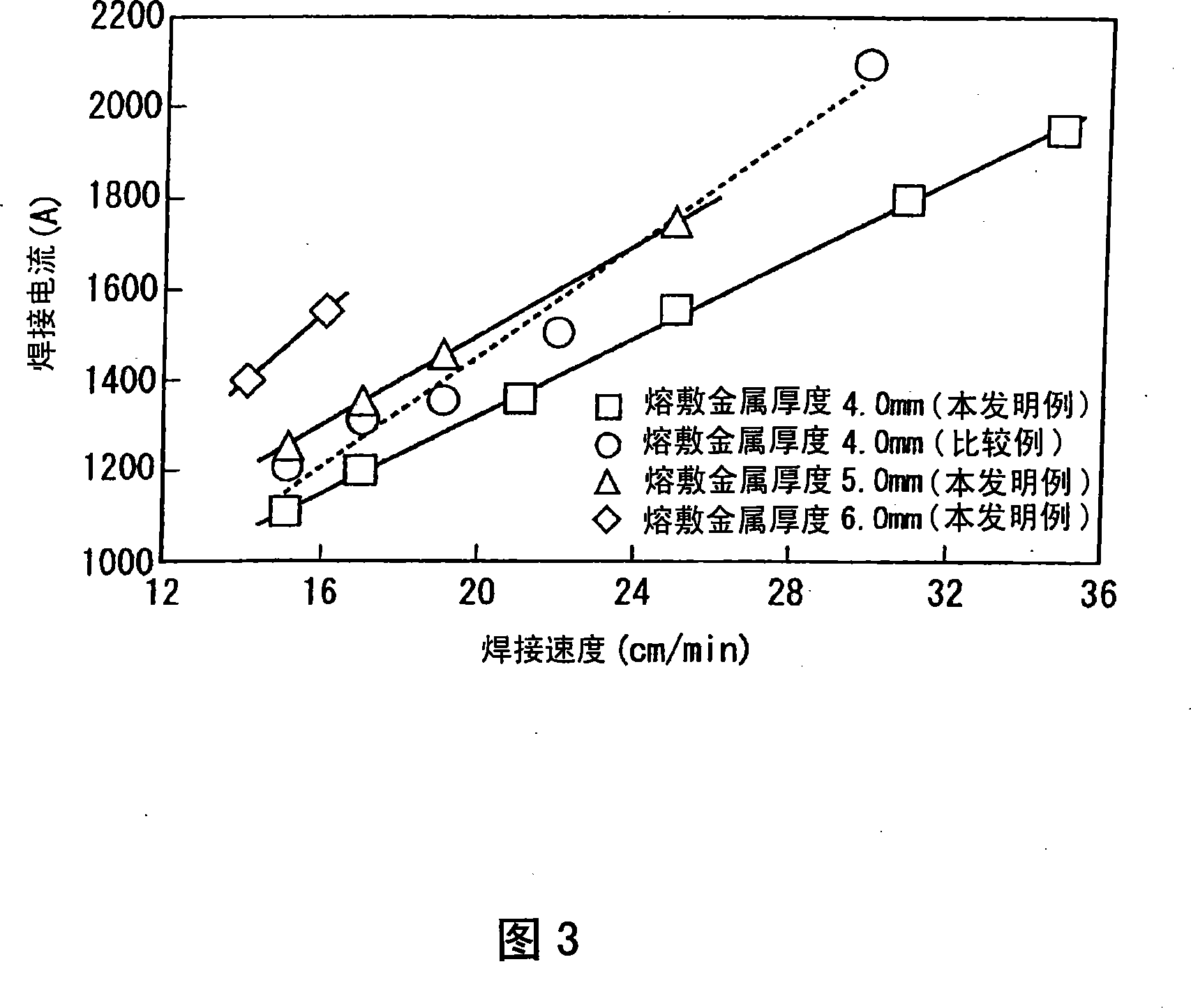

[0014] The flux for surfacing welding of the present invention is characterized in that, compared with conventional fluxes, it imparts viscosity to the molten slag and increases SiO as a molten pool flow prevention component. 2 , and will be related to the slag stripping component of CaF 2 , MgF 2 and / or AlF 3 , and the content of MgO is specified in an appropriate range, thus preventing the accompanying SiO 2 The deterioration of the slag detachability brought about by the increase. As a result, it is possible to carry out overlay welding with a deposited metal thickness of 4 mm, which is considered to be a standard deposited metal thickness, and to continue welding at a welding speed of 35 cm / min, which is higher than that of conventional fluxes (currently: 30 cm / min ), and unlike conventional welding fluxes whose upper limit is 4mm in deposited metal thickness, it is possible to perform overlay welding with deposited metal thickness of 5mm and 6mm.

[0015] Hereinafter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com