Welding method for backing ring trunnion of large converter

A large-scale converter, welding method technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of heavy workload, difficult to meet technical requirements, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

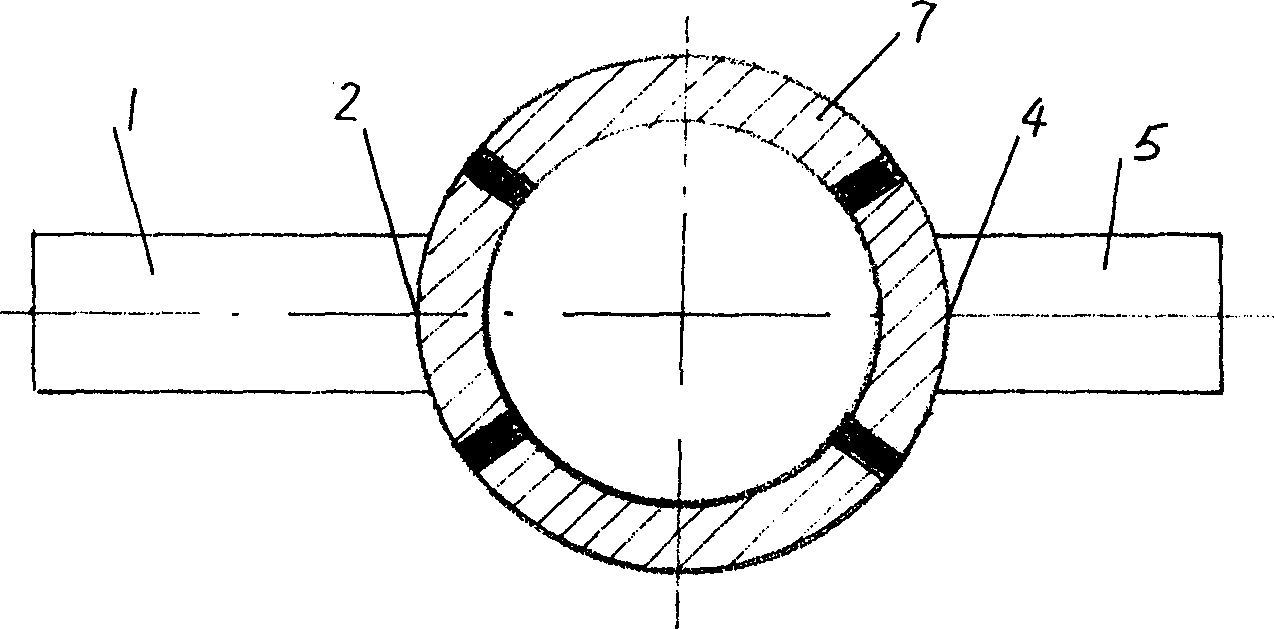

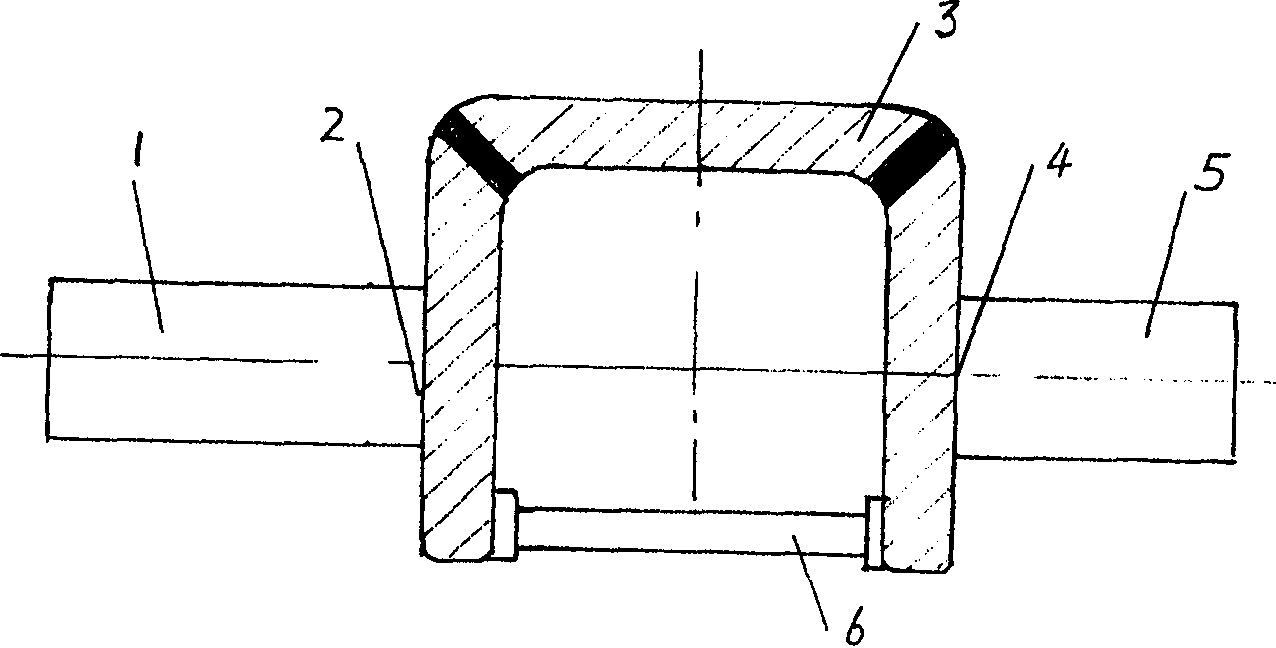

Image

Examples

Embodiment 1、 Embodiment 2

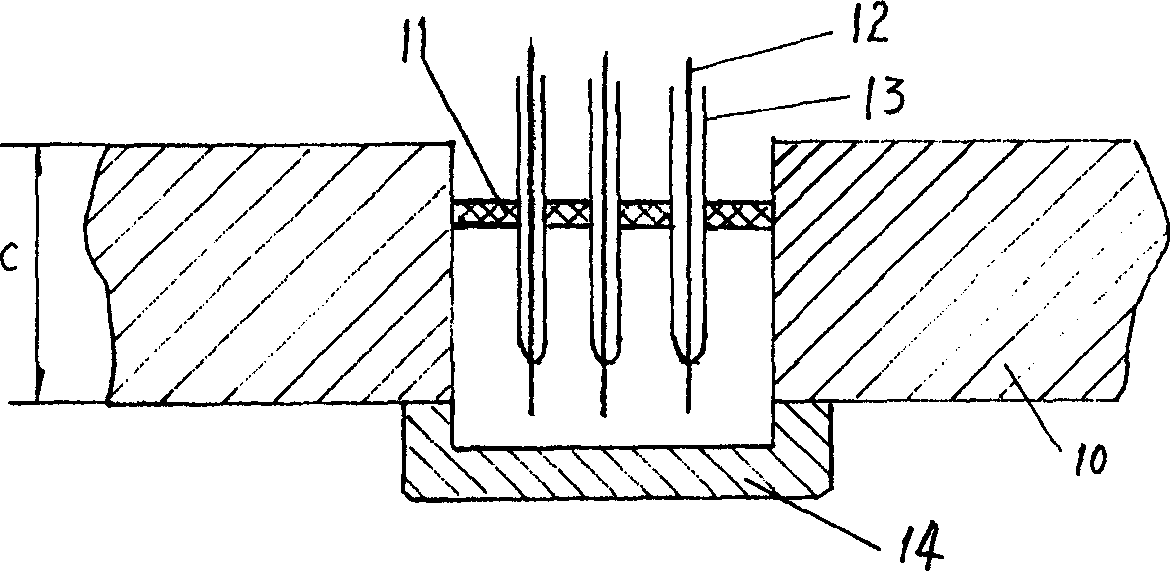

[0015] see image 3 , Figure 4 , Figure 5 , using tube-sheet electroslag welding to weld the test plate, the parameters of the test plate are as follows:

[0016] The material of the test plate is two pairs of Q235-A (equivalent to SM400B);

Embodiment 1

[0017] Embodiment 1: c=150mm, l=300mm, d=600mm;

Embodiment 2

[0018] Embodiment 2: c '=210mm, l=300mm, d=600mm;

[0019] Welding material: H10Mn2AΦ5mm, the pipe is 20# seamless steel pipe Φ14×3.

[0020] The main welding specification parameters are shown in Table 1:

[0021] Example

Welding thickness

(mm)

Number of tubes

(root)

Assembly clearance

(mm)

welding speed

(m / h)

(m / h)

welding voltage

V

(mm)

1

150

3

on 32、

Under 28

0.6~0.8

160~180

46~50

30~40

2

210

4

on 36、

Under 30

0.8~1.0

160~180

46~50

30~40

[0022] There are special requirements for 20# seamless steel pipe, which is coated with special paint on the outer layer. The thickness of the paint is 1-2mm. The main components of the paint are shown in Table 2

[0023] ingredients

Manganese ore p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com