Fire-proof material product for concrete structure and construction technique thereof

A technology of concrete structures and fireproof materials, which is applied in fire prevention and building components, etc., can solve problems such as poor temperature blocking effect and structural damage, and achieve the effects of alleviating heat transfer, eliminating maintenance, and ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

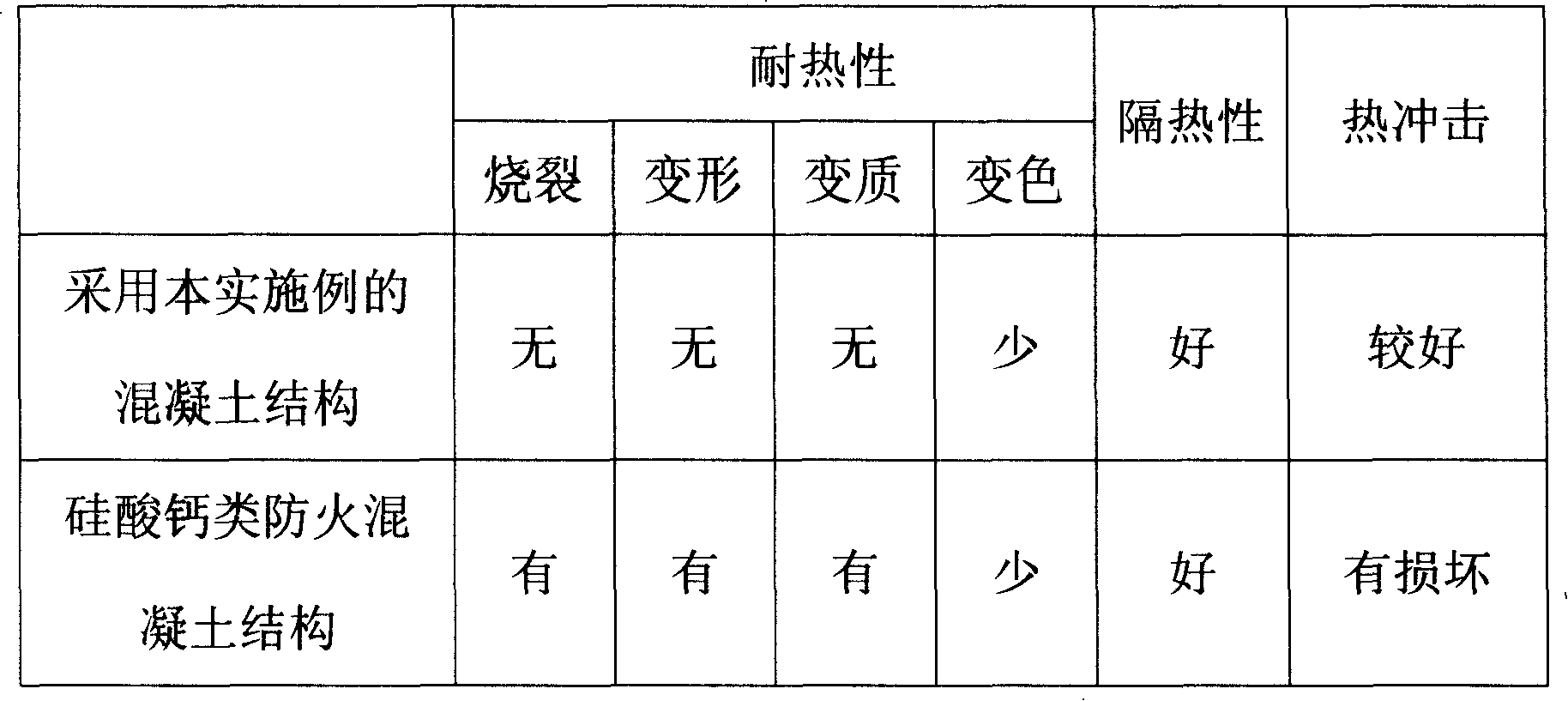

Examples

Embodiment Construction

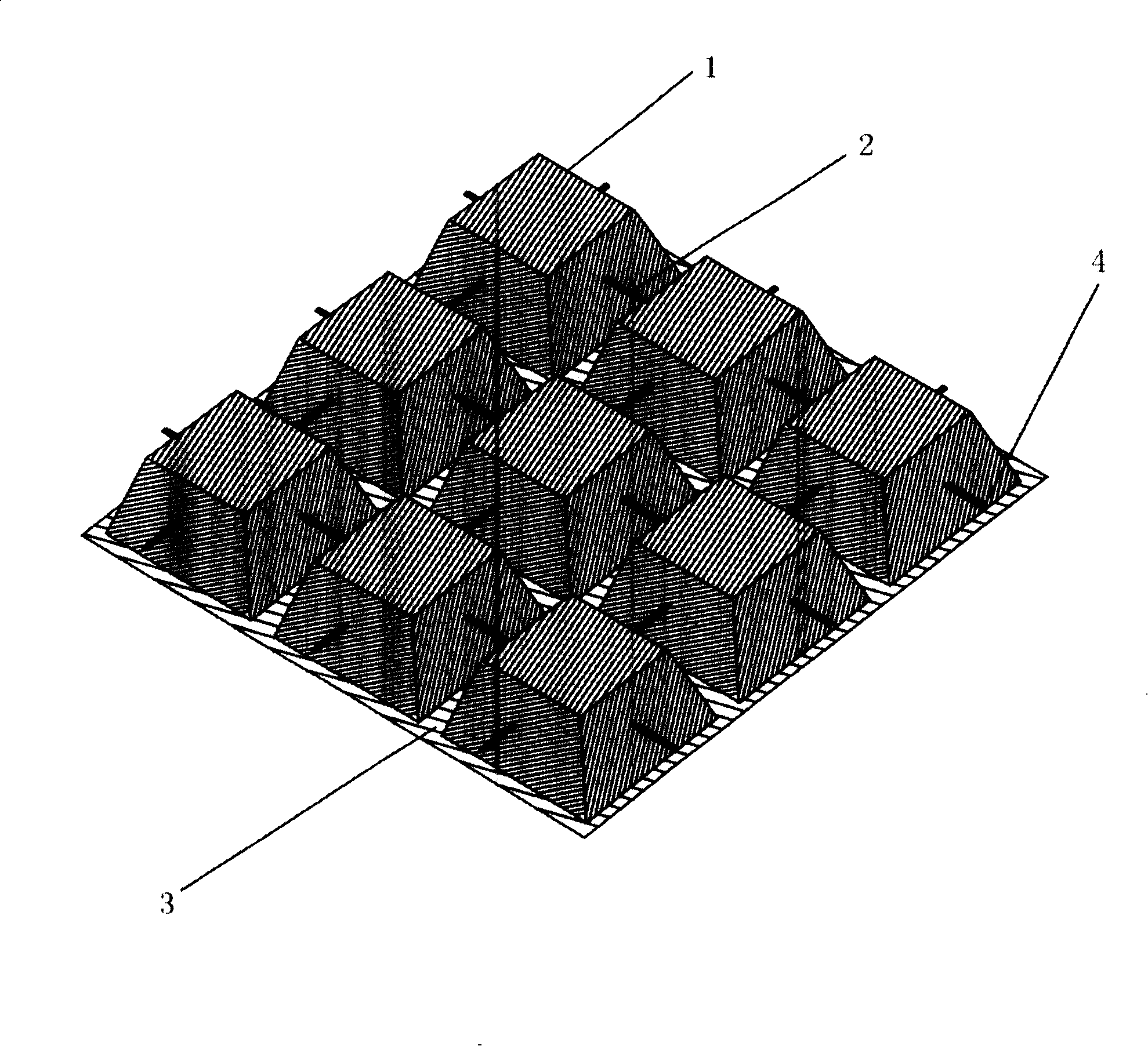

[0009] figure 1 Structural diagram of regular quadrilateral conical fireproof material products

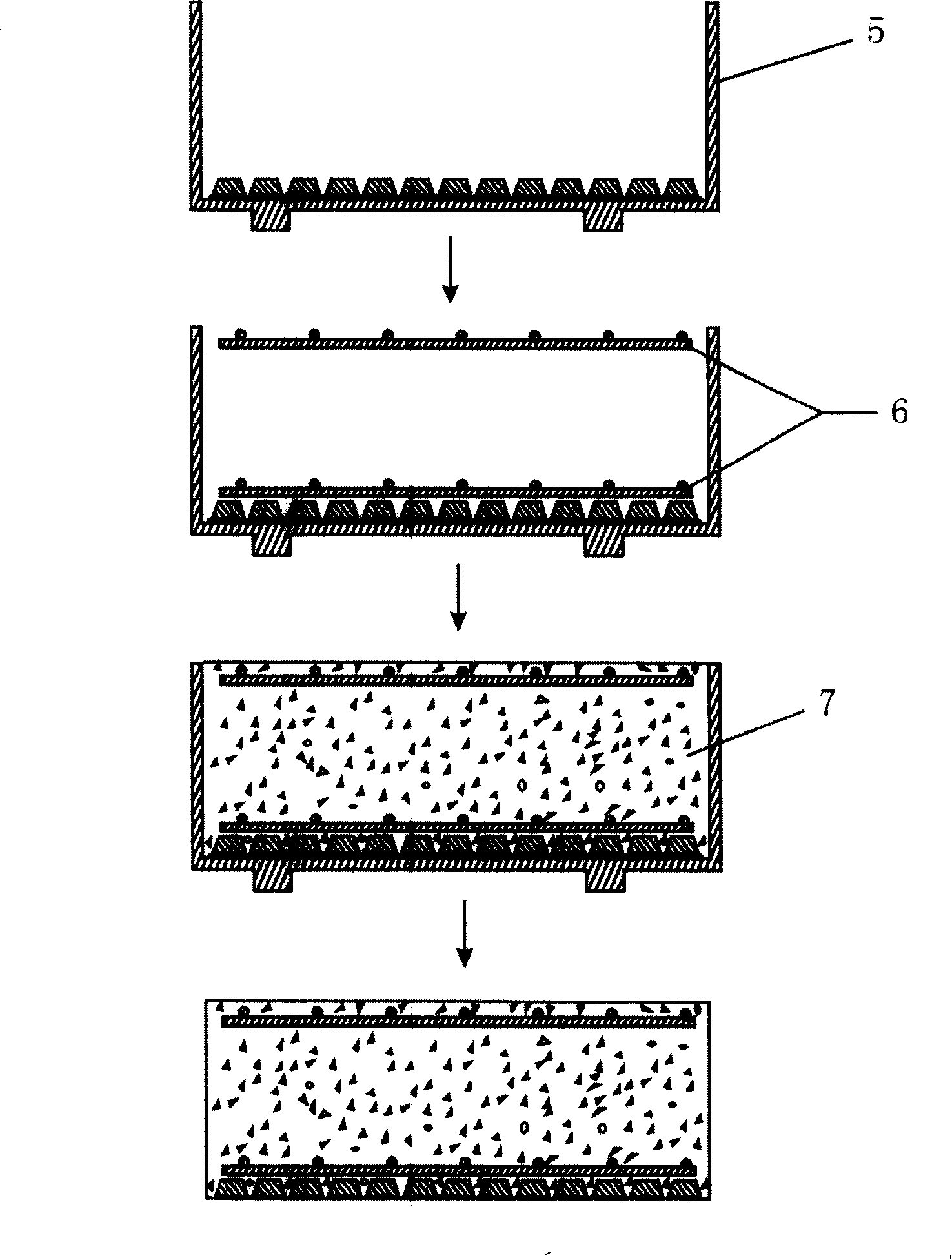

[0010] figure 2 Schematic diagram of the construction process of a fireproof material product used in concrete structures

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] This embodiment provides a regular quadrilateral conical fireproof material product for concrete structures, which consists of 9 standard regular quadrilateral conical fireproof blocks 1 that use high-density cement-based fireproof materials and are arranged equidistantly in a two-dimensional 3×3 pattern. The above-mentioned standard quadrilateral conical fire block 1 has an upper bottom surface of 40mm×40mm, a lower bottom surface of 60mm×60mm, and a height of 27mm. On the larger surface of 60mm×60mm, a layer of 3mm thick pure cement is attached to the lower bottom surface. Surface layer: the above 9 standard regular quadrilateral conical fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com