Hydraulic digital controller

A digital control and hydraulic technology, applied in the field of digital hydraulics, can solve problems such as limitation of solenoid valve response capability, system efficiency drop, and throttling loss, and achieve the effects of precise control, high output pressure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

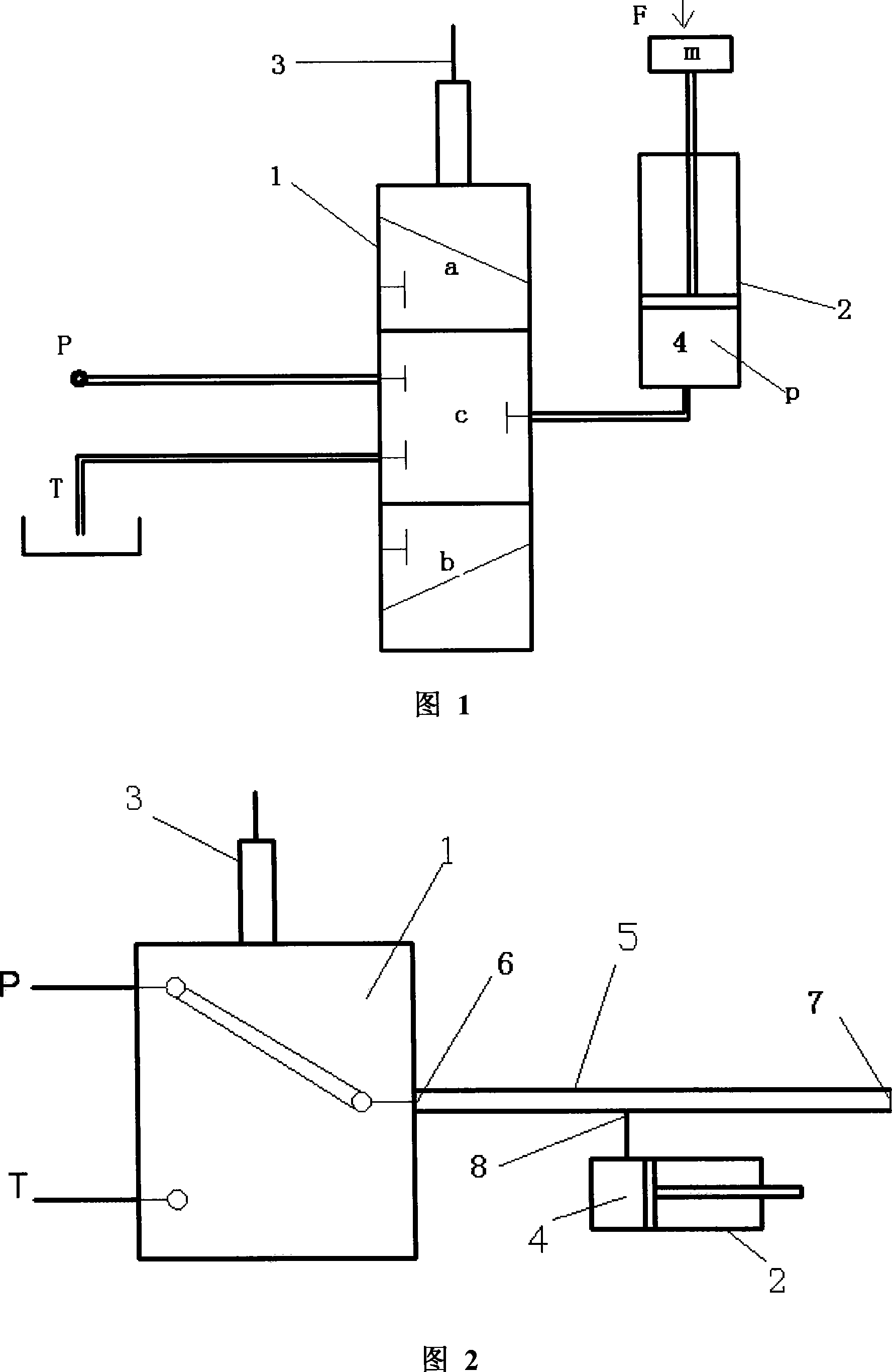

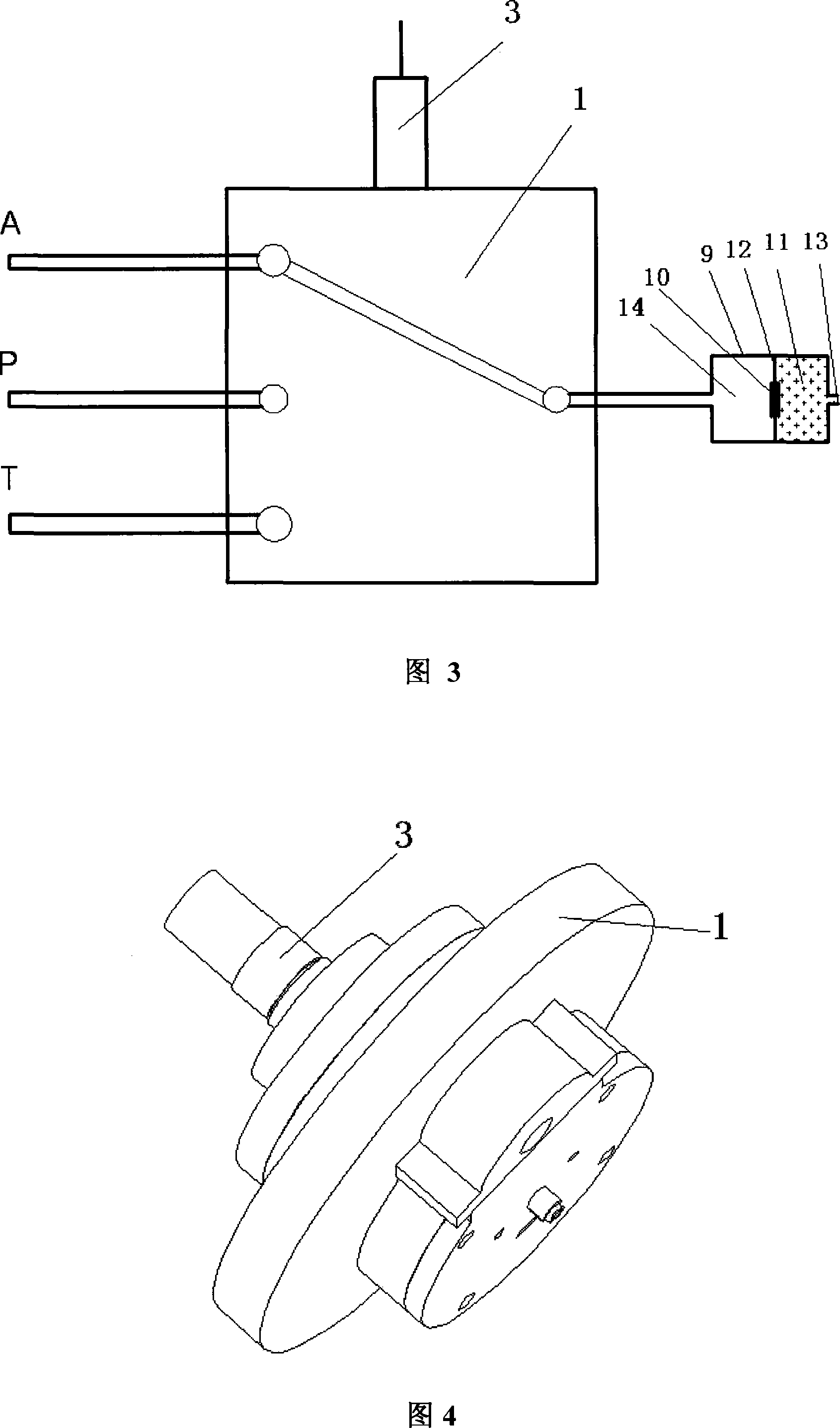

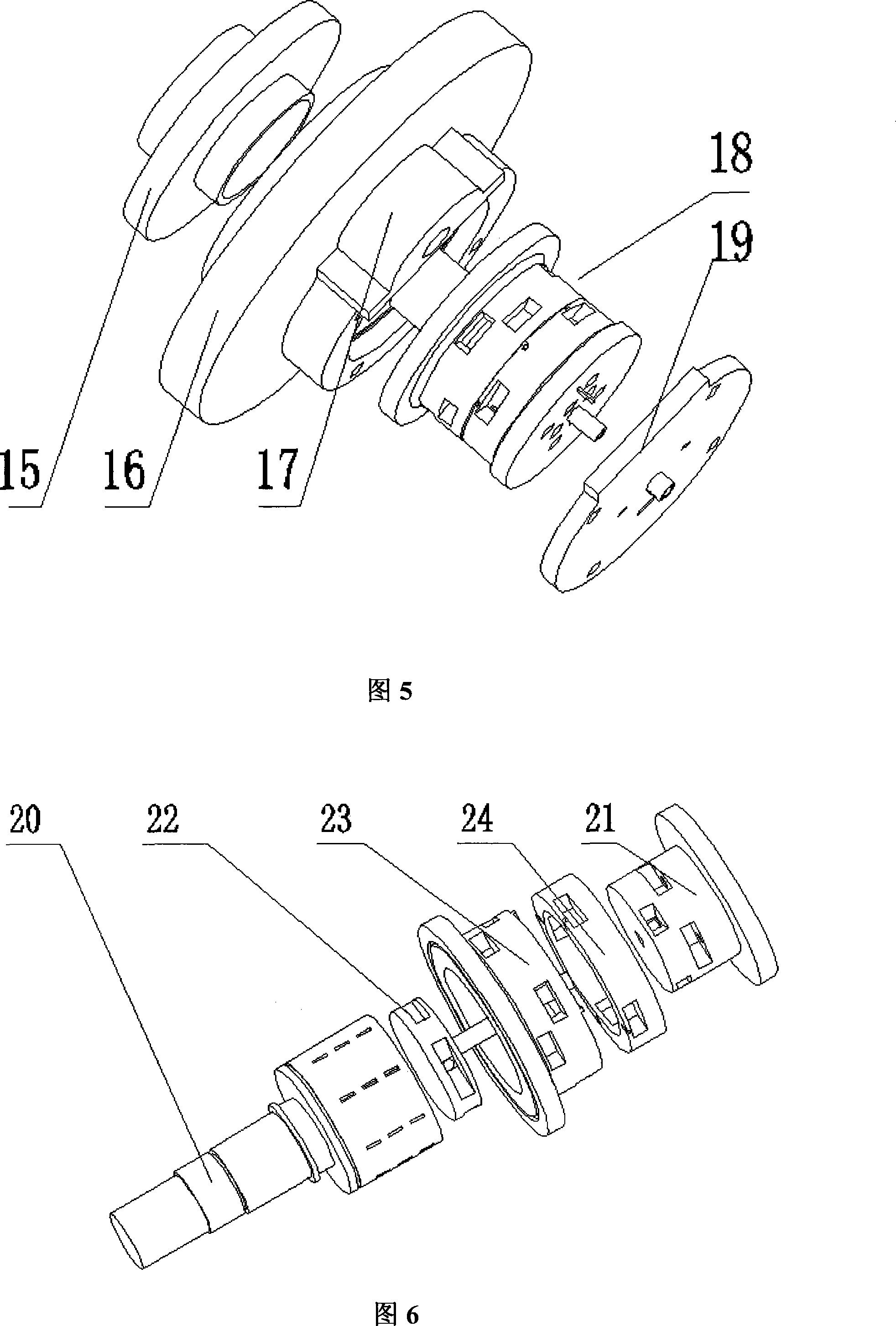

[0033]Referring to Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 7, the hydraulic digital control device includes a control mechanism 3 to control a controllable reversing valve 1 to connect the oil circuit P of the oil pump, the oil circuit T connected to the oil tank and The switching between the oil circuit A that connects the load, the control mechanism is a rotor 20 driven by a motor, and the controllable reversing valve 1 is a rotary three-way valve composed of a flow distribution member matched with the rotor 20 Road reversing valve; the rotary three-way reversing valve controls the oil circuit A, and the oil circuit P and the oil circuit T are interchangeably connected to the resonance cavity 14 of an adjustable resonance device 9 . The rotor 20, the rotary three-way reversing valve, the oil passage P, the oil passage T, the oil passage A and the resonan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap