Measurement equipment and its measurement method

A technology for measuring equipment and measuring values, applied in measuring devices, mechanical measuring devices, mechanical thickness measurement, etc., can solve problems such as low efficiency, increased work intensity of inspectors, reading errors, etc., and achieve simple measurement methods, easy operation, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

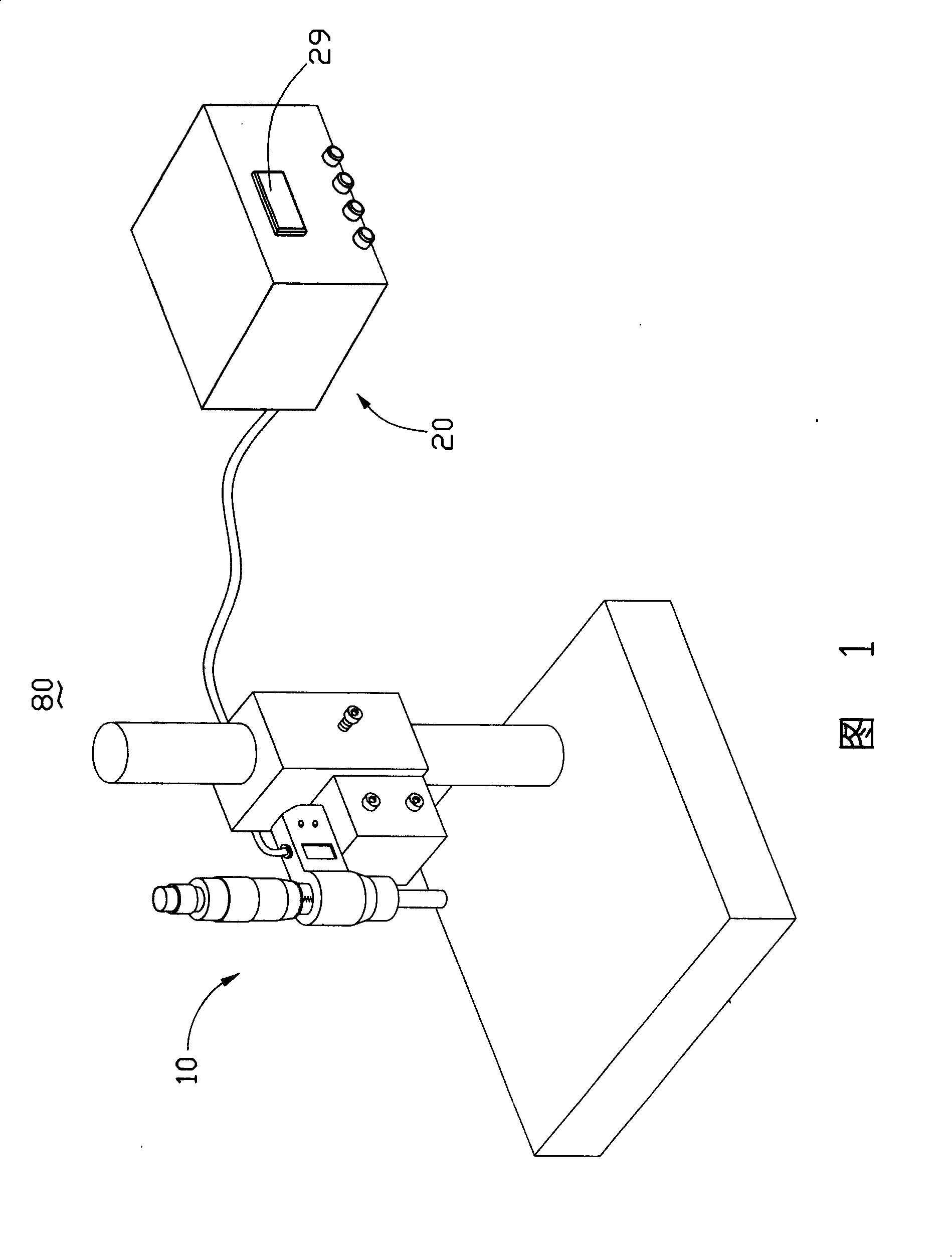

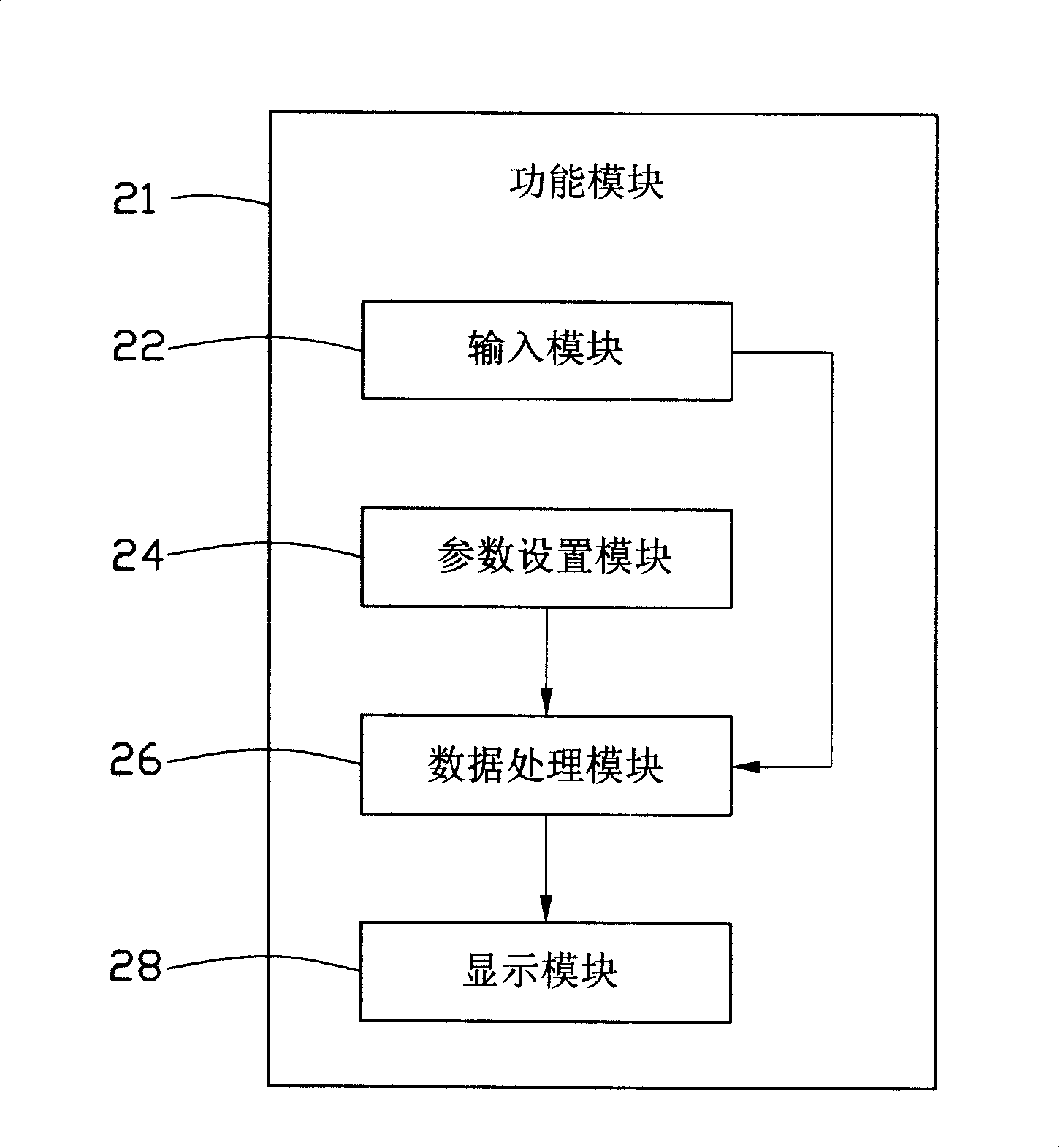

[0016] Please refer to Fig. 1, the preferred embodiment of measuring equipment 80 of the present invention comprises a measuring instrument 10 and a data processing device 20 interconnected with this measuring instrument 10, and this measuring equipment 80 can be used for the height, width and thickness etc. of workpiece Geometric parameters are measured and indicated whether the workpiece complies with the standard.

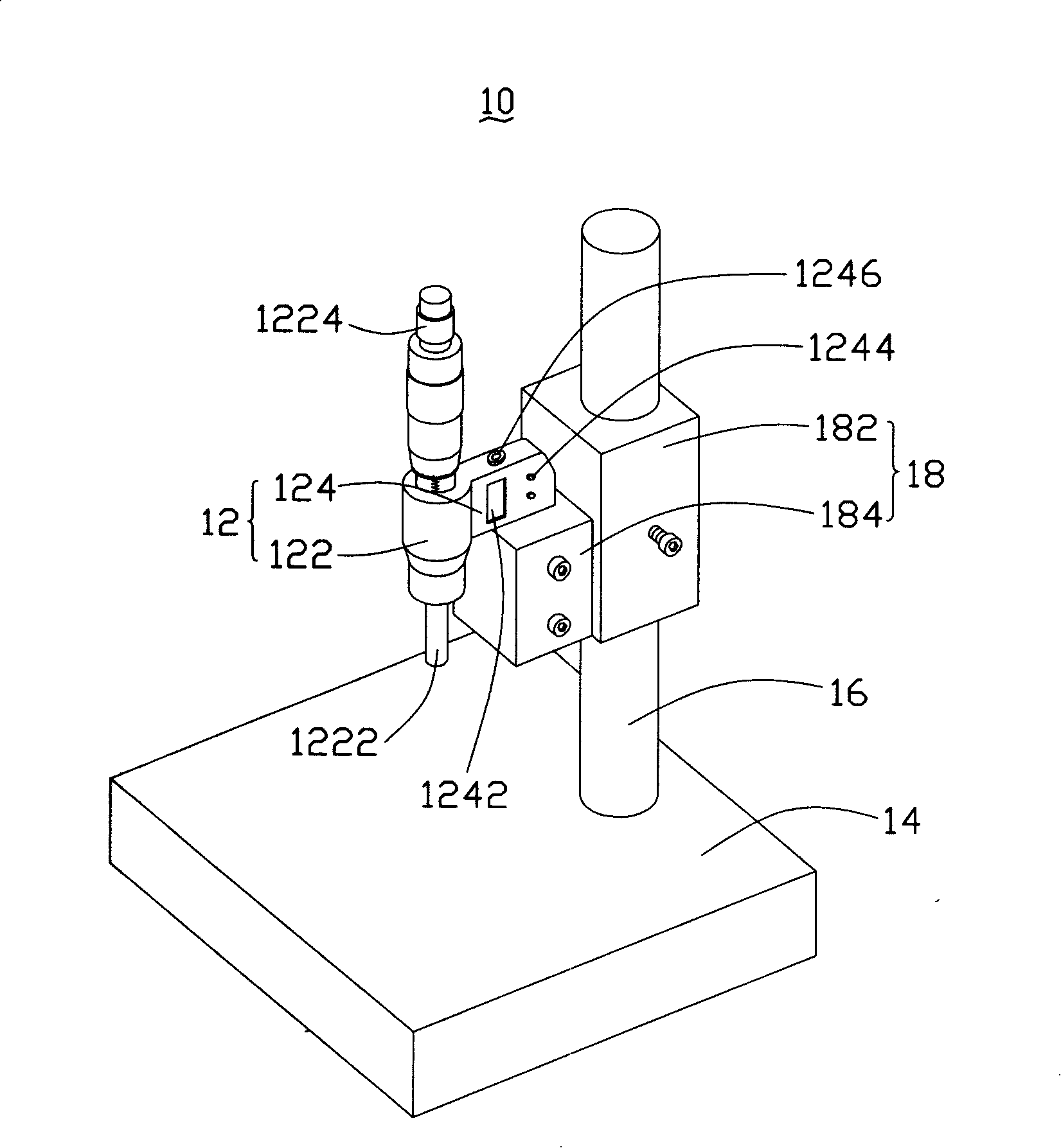

[0017] see figure 2 , the measuring instrument 10 includes a base 14 , a guide post 16 , a slider 18 and a micrometer 12 . The base 14 is a substantially rectangular metal plate with a high flatness on its upper surface. A through hole (not shown) is opened near the edge of the upper surface. The guide post 16 is a metal rod whose cross-section is equivalent to the size of the through hole. The guide post 16 can be fixed in the through hole and perpendicular to the base 14 . The slider 18 includes a sliding portion 182 and a clamping portion 184. The sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com