Photochromic translucent material before and after color alteration transmittance detection method

A light-transmitting material and photochromic technology, applied in the field of optics, can solve problems such as unreliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

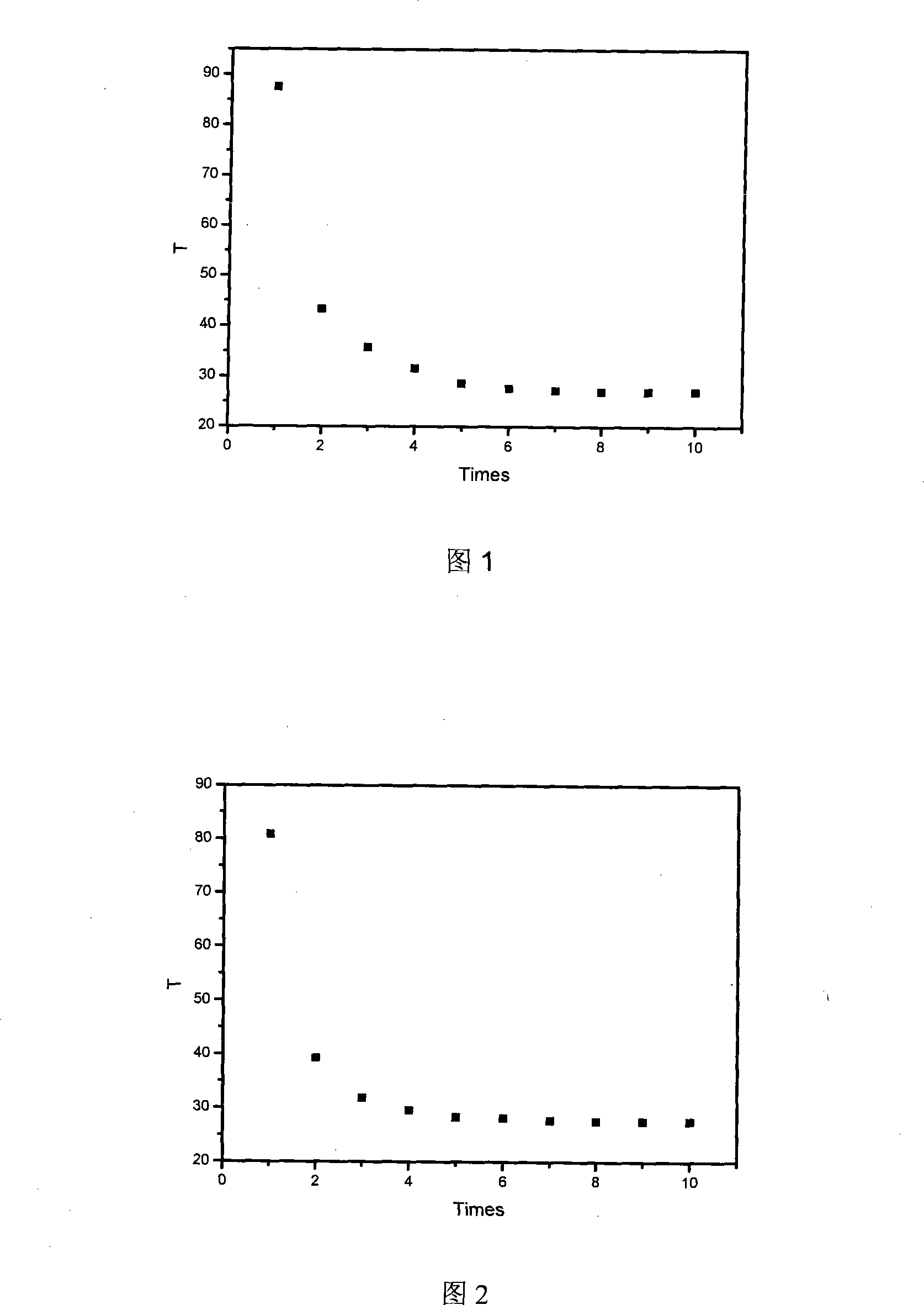

Embodiment 1

[0033] It adopts flat brown PMMA resin lens with hard coating, and the thickness is 1mm. The transmittance of the samples was tested on a Topcon TM-2 spectrophotometer. Using the common method, the tested transmittance before and after the color change are 80.89% and 32.2% respectively. Using this method, the transmittance of a piece of resin lens is first detected to be 80.89%, and the logarithm is 0.09, which is recorded as A1; then the two sheets are superimposed, and the transmittance of the sample is detected to be 74.90%, and the logarithm is 0.1255, Denote it as A2; then superimpose the three pieces, it is detected that the transmittance of the sample is 72.03%, take the logarithm as 0.1425, and record it as A3; then superimpose the four pieces, it is detected that the transmittance of the sample is 69.26%, take the The number is 0.1595, recorded as A 4 ; because A 4 -A 3 =A 3 -A 2 , so T=10 -A =10 -(An-An-1) = 96.16%.

[0034] Also take out a resin lens withou...

Embodiment 2

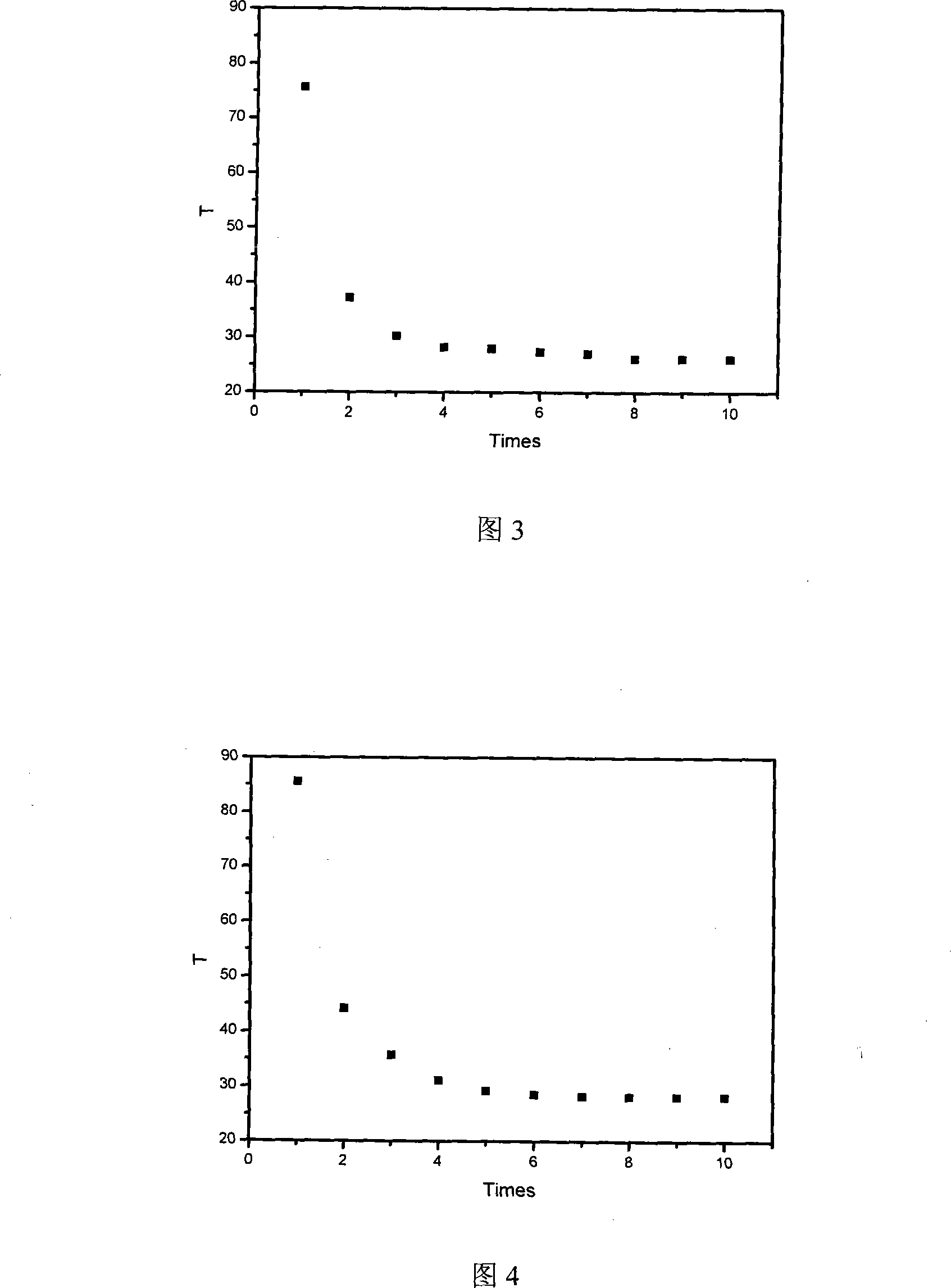

[0036] It adopts flat brown PMMA resin lens with a thickness of 2mm. The transmittance of the samples was tested on a Topcon TM-2 spectrophotometer. Using a common method, the tested transmittances before and after discoloration are 75.63% and 28.7%, respectively. Using the same method, test the transmittance of 4, 6, 8mm thick resin lenses, respectively: 70.26%, 64.88% and 60.12%. Taking the logarithm of the transmittance, it can also be obtained because A 4 -A 3 =A 3 -A 2 , so T=10 -A =10 -(An-An-1) = 92.46%.

[0037] Also take out a piece of resin lens without discoloration, and use the method of 2 times per second to detect the transmittance after the complete discoloration, and the number of tests is 10 times. Figure 3 is obtained, and the test result is 26.12%.

Embodiment 3

[0039] It adopts flat gray hardened polyurethane resin lens with a thickness of 1mm. The transmittance of the samples was tested on a Topcon TM-2 spectrophotometer. Using a common method, the tested transmittances before and after discoloration are 85.23% and 33.25%, respectively. Using this method, the transmittance of a resin lens is first detected to be 85.23%, and the logarithm is 0.069, which is recorded as A 1 ; Then the two sheets are superimposed, and the transmittance of the sample is detected to be 76.83%, and the logarithm is 0.1144, which is recorded as A 2 ; Then the three pieces are superimposed, and the transmittance of the sample is detected to be 74.71%, and the logarithm is 0.1266, which is recorded as A 3 ; Then the four pieces are superimposed, and the transmittance of the sample is detected to be 72.64%, and the logarithm is 0.1388, which is recorded as A 4 ; because A 4 -A 3 =A 3 -A 2 , so T=10 -A =10 -(An-An-1) = 97.23%.

[0040] Similarly, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com