Method for extracting property of gas sensor output, and device and method for measuring gas density using it

A gas concentration measurement and gas sensor technology, which is used in measurement devices, special data processing applications, instruments, etc., and can solve the problems of different gas sensor characteristics, unstable output results, and failure to clearly explain the output characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

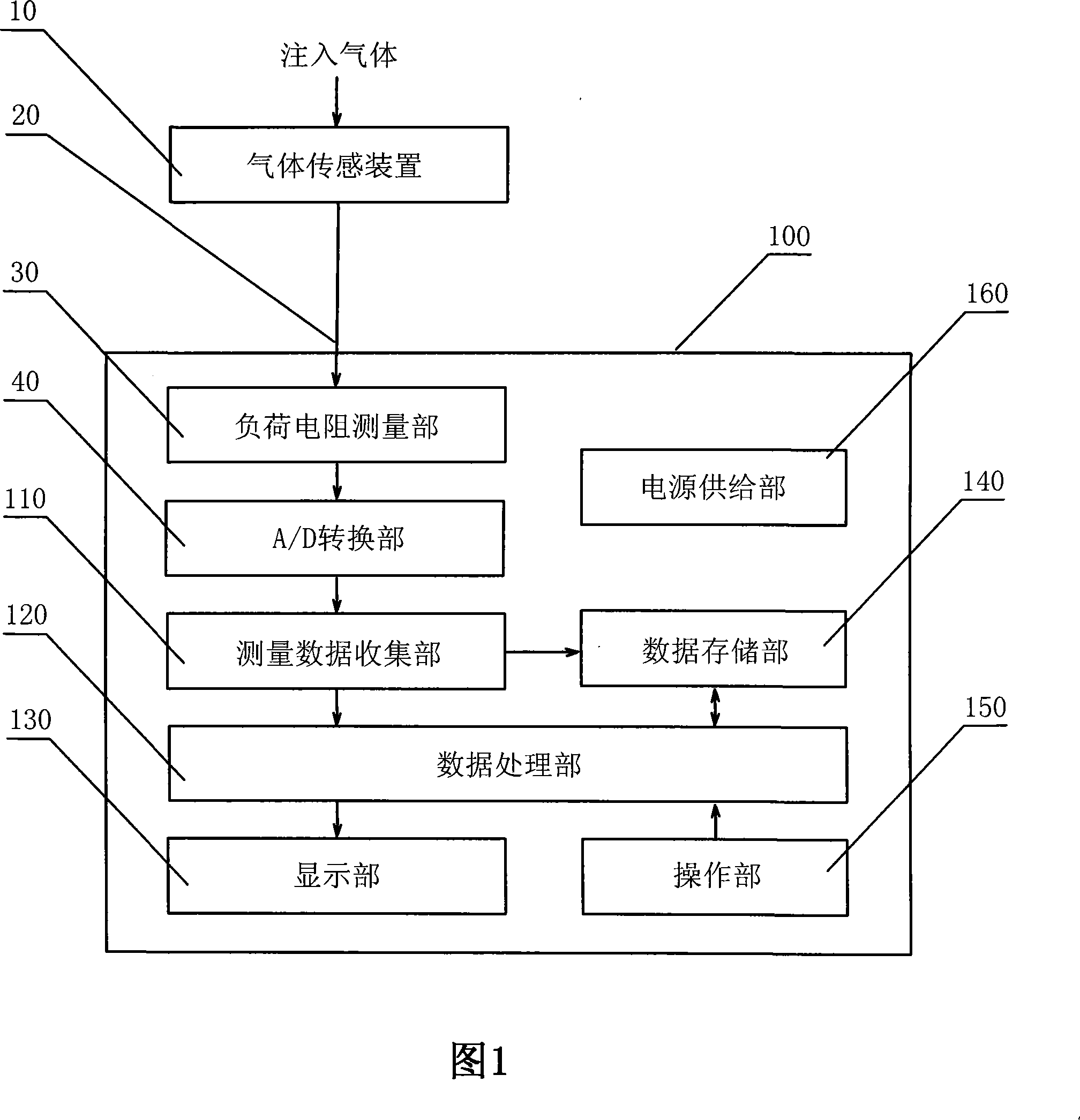

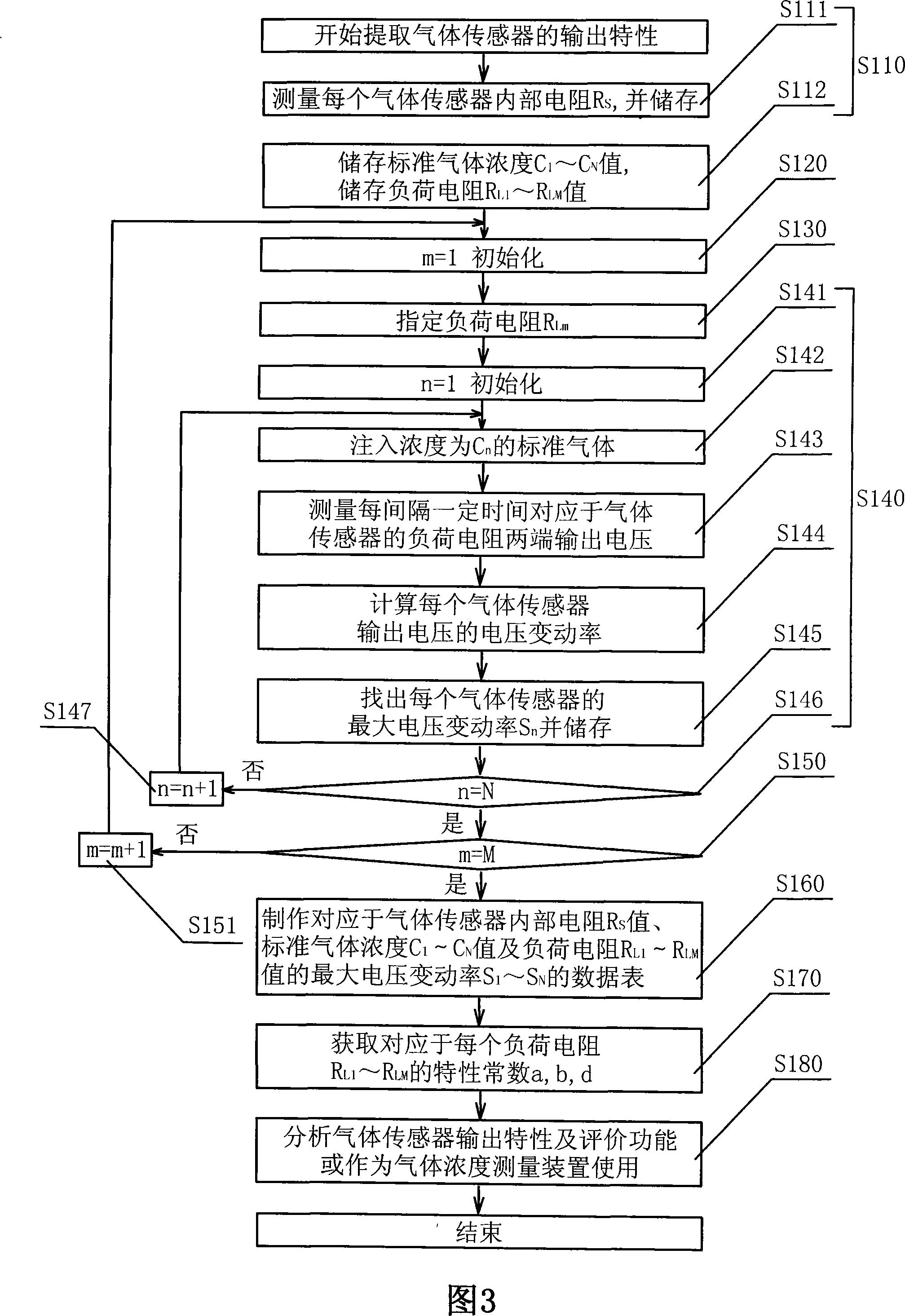

[0031] FIG. 1 is a block diagram of a gas sensor output characteristic data measurement system for extracting gas sensor output characteristics according to Embodiment 1 of the present invention.

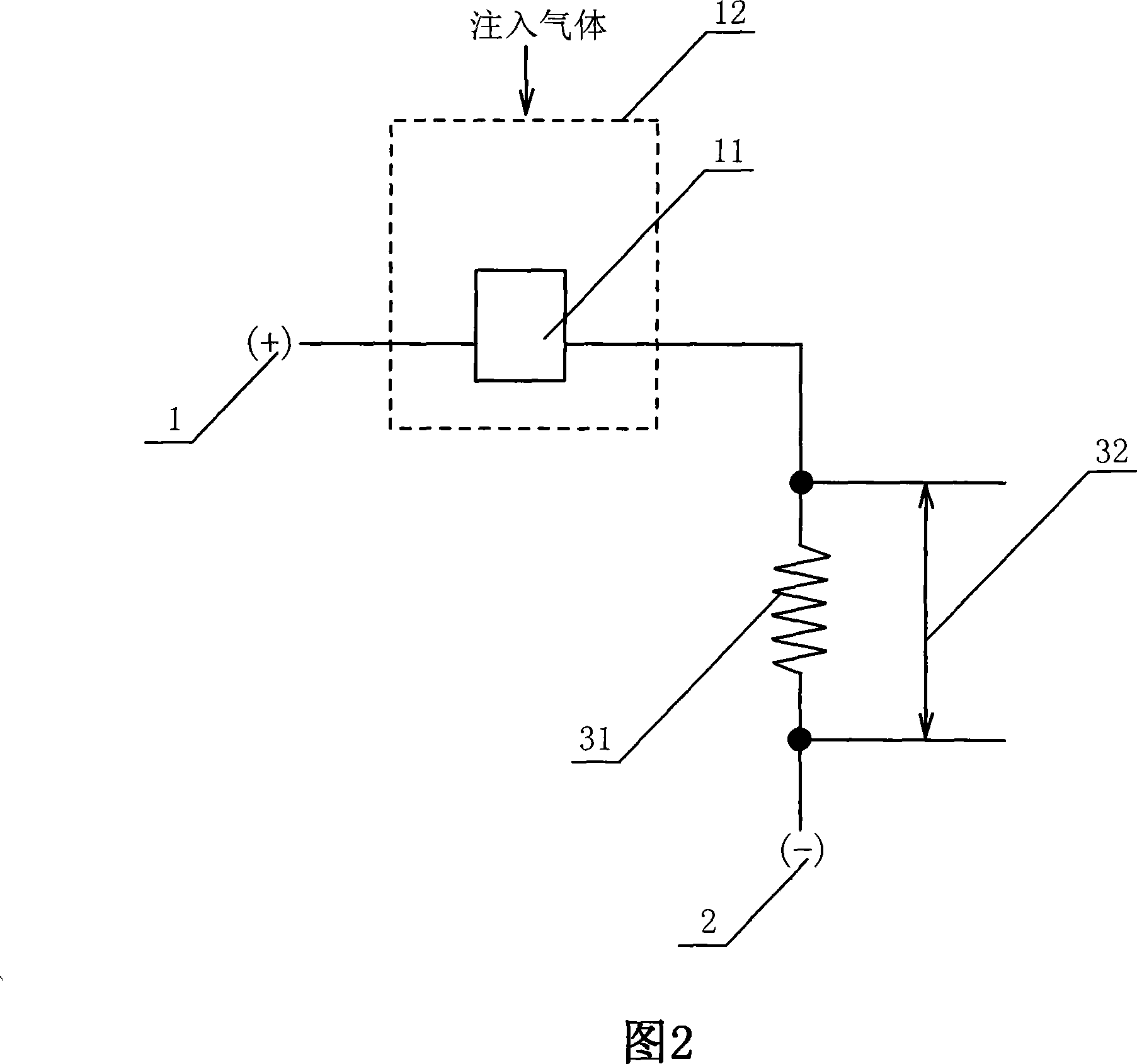

[0032] As shown in Fig. 1, the output characteristic data measuring system of gas sensor 11 is composed of a gas chamber 12 temporarily filled with gas for sensing gas, a gas injection device capable of injecting gas into the gas chamber 12, and a gas injection device arranged in the gas chamber. The gas sensing device 10 of at least two semiconductor gas sensors 11 in 12; the sensor connection wire 20 drawn from the gas sensor 11 and connected to the outside; the signal of the gas sensor 11 transmitted through the sensor connection wire 20 A gas sensor characteristic data measuring device 100 is configured to decode and calculate the gas sensor characteristic data, and then measure the gas sensor characteristic data.

[0033] The gas sensor characteristic data measuring device 100 ...

Embodiment 2

[0067] Fig. 9 is a flow chart of a method for acquiring the maximum voltage change rate data of a gas sensor according to Embodiment 2 of the present invention.

[0068] The method for obtaining the data of the maximum voltage change rate S of the gas sensor as shown in FIG. 9 can be implemented by using the device shown in FIG. 1 , so detailed description is omitted. However, the data processing unit 120 does not perform calculations to obtain the characteristic constants a, b, and d, but only stores the selected maximum voltage variation rate S corresponding to the concentration C of the standard gas in the data storage unit 140 .

[0069] As shown in Figure 9, the acquisition method of the maximum voltage change rate S data of the gas sensor includes: storing the standard gas concentration value C 1 ~C N , determine and store the load resistance value R L The stage S310 of standard gas programming sequence number n, and the stage S321 of initializing the sequence number n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com