Steel rail weld joint identification method and its special equipment

A technology for welding joints and special devices, applied in display devices, marking, printing, etc., can solve the problems of low utilization rate of welding production data and difficult historical records, and achieve the effect of simple structure, easy identification and unified management, and guaranteeing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

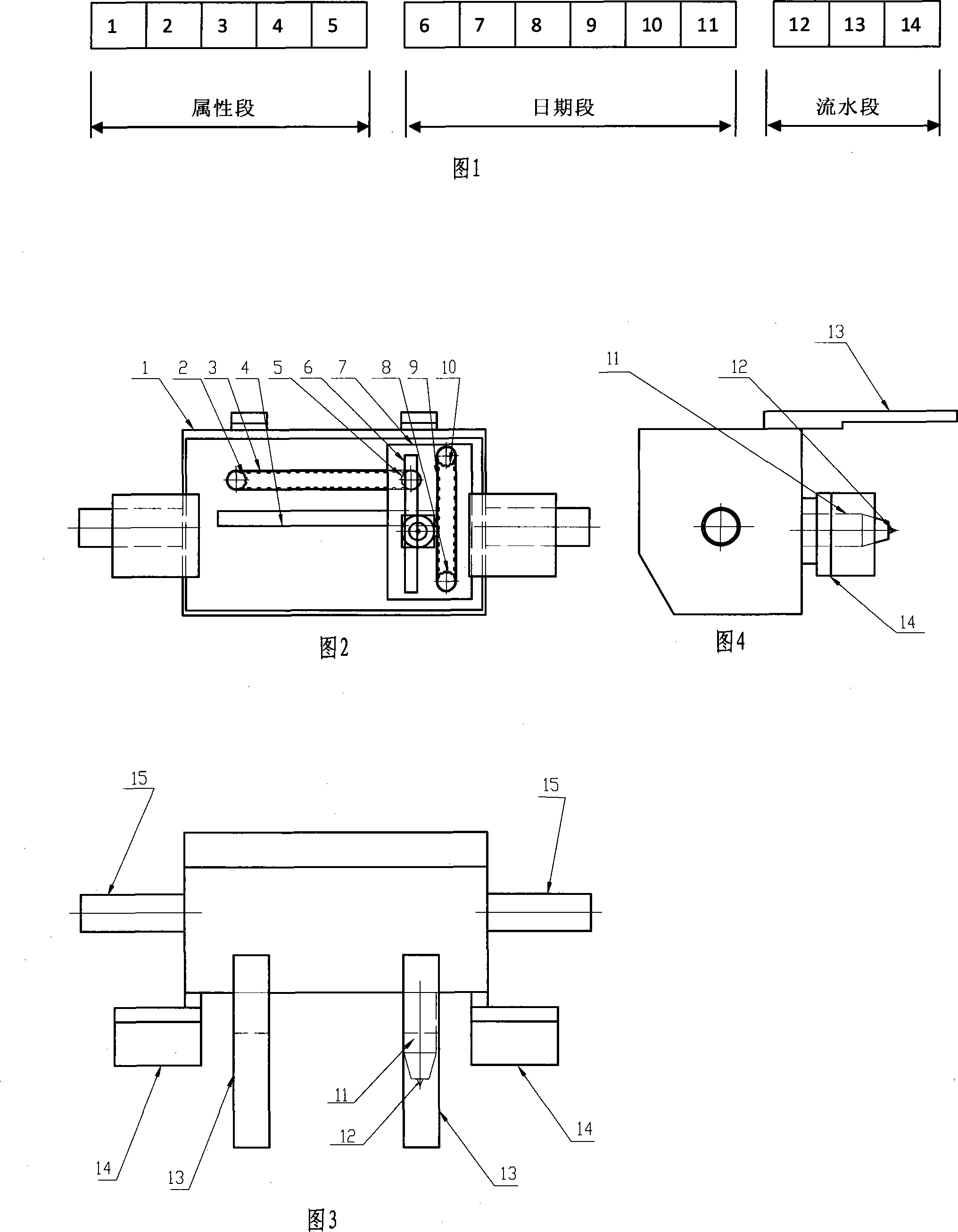

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] The inventor has learned through theoretical analysis that the upper part of the rail waist (ie the neutral axis of the rail) is subjected to compressive stress and the lower part is subjected to tensile stress, and the stress at the rail waist is zero. It has been proved by experiments that the pit mark is set on the rail waist of the rail, specifically within 10mm of the rail waist on the side of the non-working surface of the rail, and the depth is in the range of 0.3-0.5mm. The pit mark will not only make the rail Fatigue cracks, fractures, reducing the service life of the rail, and can keep the pit marks for about 10 years, overcoming people's long-standing technical prejudices.

[0025] In order to ensure the traceability and unified management of quality, the pit marks are marked a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com