Jacquard ultra-thin non-convex harness cord sheath

A jacquard machine and casing technology, which is applied in the direction of jacquard machines, heddles, textiles, etc., and can solve problems such as loose casing and casing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

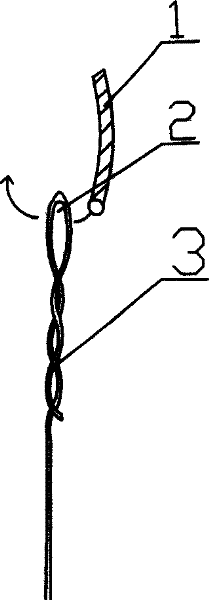

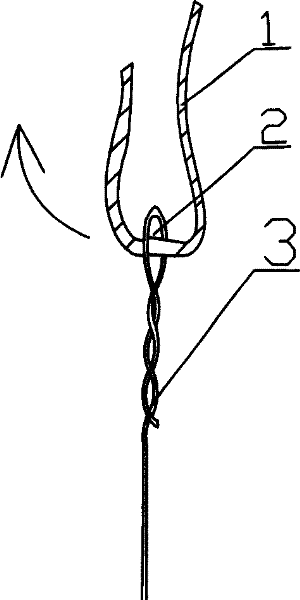

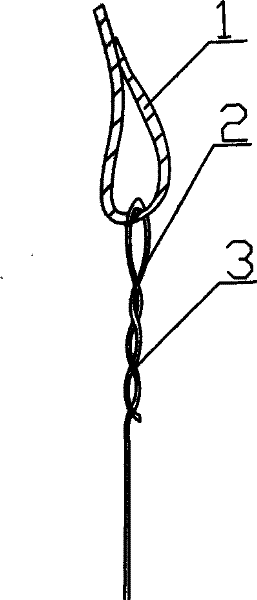

[0015] Such as Figure 7 , Figure 8 The jacquard ultra-thin non-protruding through wire sleeve shown is made of a hollow tubular body, and the cross-sectional shape of the hollow cavity of the sleeve 4 is a four-leaf shape (the cross-sectional shape of the hollow cavity in the sleeve 4 can also be a cross shape. ), the axis of each leaf tube is parallel and equal to the axis of the sleeve, and the axis of each leaf tube can also rotate around the axis of the sleeve, so that the hollow tube lumen rotates like the rifling in the gun barrel. Such as Figure 9 , Figure 10 As shown, one end of the harness rope 1 passes through the upper clip eye 2 of the heald 3, the harness rope 1 is cross-connected with the heald 3, the casing 4 is lifted upward, and the harness rope 1 and the heald 3 are in the sleeve The inside of the tube 4, because the inside of the sleeve 4 is a special four-leaf shape, so that the intersection of the wire rope 1 and the heddle 3 does not make the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com