Sliding chute positioning link bar

A connecting rod and chute technology, which is applied to building components, covering/lining, construction, etc., can solve the problems of high cost, difficulty, sale or scrap of old furniture, etc., and achieve the effect of reducing cost, improving efficiency, and flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

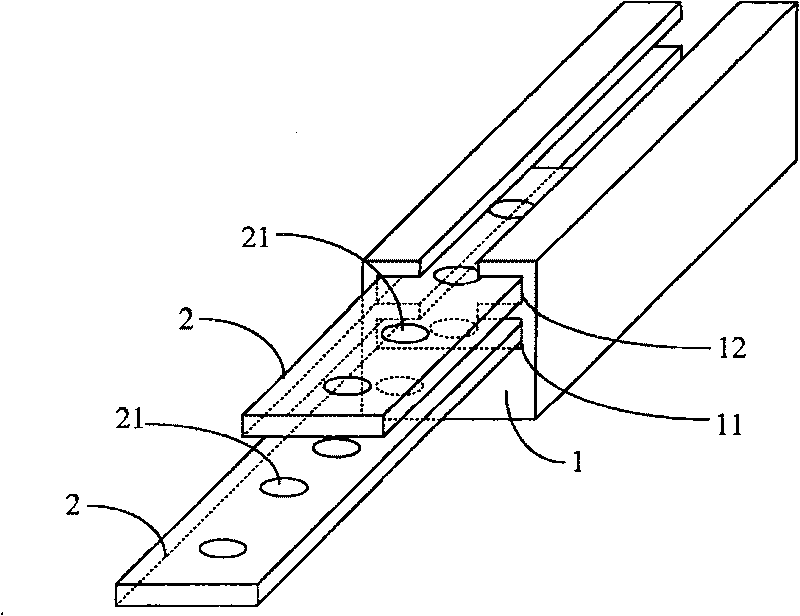

[0044] figure 1 Shown is a basic embodiment of the present invention, which includes a cylinder 1, and the surface of the cylinder 1 is provided with a double-layer chute group composed of a lower chute 11 and an upper chute 12 superimposed. The lower floor chute 11 and the upper floor chute 12 are linear chutes whose inner width dimension is greater than the notch width dimension, and its cross-sectional shape is "convex". The notch of the lower floor chute 11 is located at the bottom of the upper floor chute 12 . Two sliding sheets 2 are matched in the lower chute 11 . A slide plate 2 is matched in the upper chute 12 . Sliding plate 2 can only slide linearly in the double-layer chute group. The sliding sheet 2 is also provided with a plurality of screw holes 21 for fixing the sliding sheet 2 and external mounting parts by bolts.

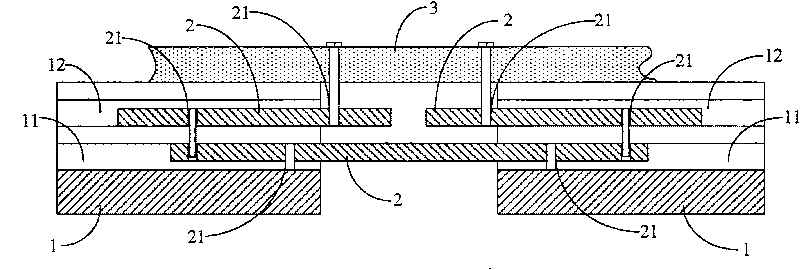

[0045] The basic purposes of the lower chute 11, the upper chute 12 and the slide 2 are as follows: figure 2 shown.

[0046] figure 2 Amo...

Embodiment 2

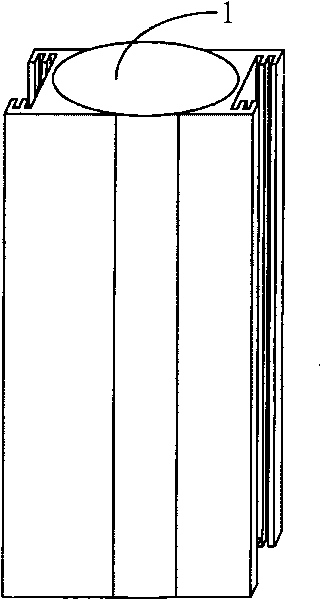

[0050] image 3 Shown is an embodiment with two double chute sets. In this embodiment, the cross-sectional shape of the cylinder 1 is circular. The setting directions of the two double-layer chute groups are in the same direction, and adopt a symmetrical manner. When the keel bracket is formed in this embodiment, since there are two sets of double-layer chute groups arranged symmetrically, other components, such as plates and other devices, can be installed and fixed in two directions of the keel bracket.

Embodiment 3

[0052] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned second embodiment is that: the cross-sectional shape of the cylinder 1 is an annular rectangle; 11. The lower chute 11 is provided with a sliding piece 2 . The two lower chutes 11 are also arranged symmetrically, so that there are chutes on the surface of the cylinder composed of four sides, of which two are double-layer chute groups, and the other two are lower chute 11. . The hollow cylinder 1 can save a lot of raw materials, especially when the cylinder 1 is manufactured in large quantities by extruding non-ferrous metals.

[0053] In this embodiment, the state when a plurality of cylinders are axially connected is as follows: Figure 5 shown. exist Figure 5 Among them, since two adjacent cylinders 1 have lower sliding grooves 11, four sliding pieces 2 can be used for axial connection, so that the connection strength is greatly improved. In addition, when using this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com