Curtain plate type roller-blind door

A rolling shutter door and curtain plate technology, which is applied in the direction of windows/doors, door/window protection devices, shutters/movable grilles, etc., can solve the problems of difficult guide grooves coming out, inability to disengage, tilting to one side, etc., to prevent abutting failure, the effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

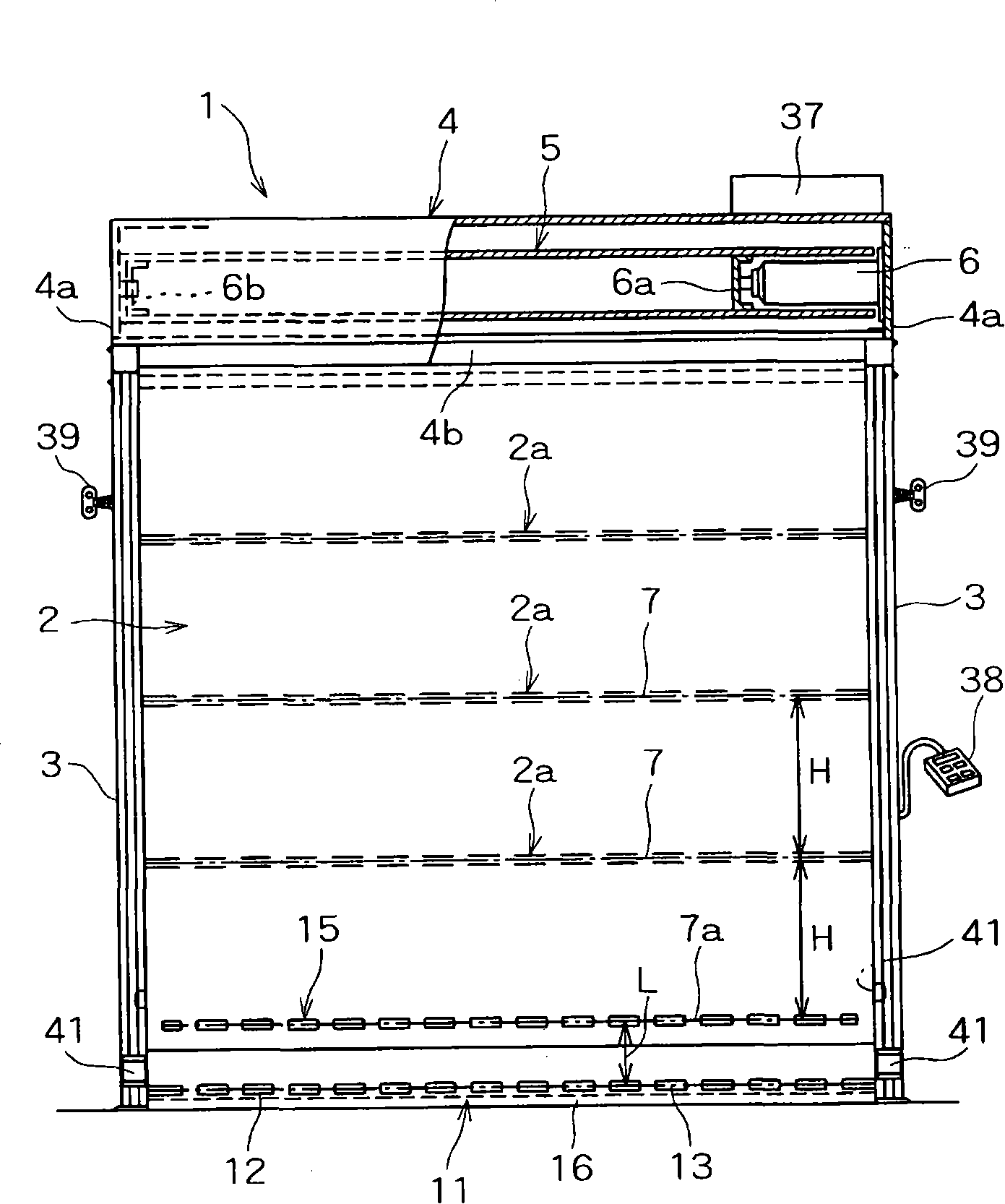

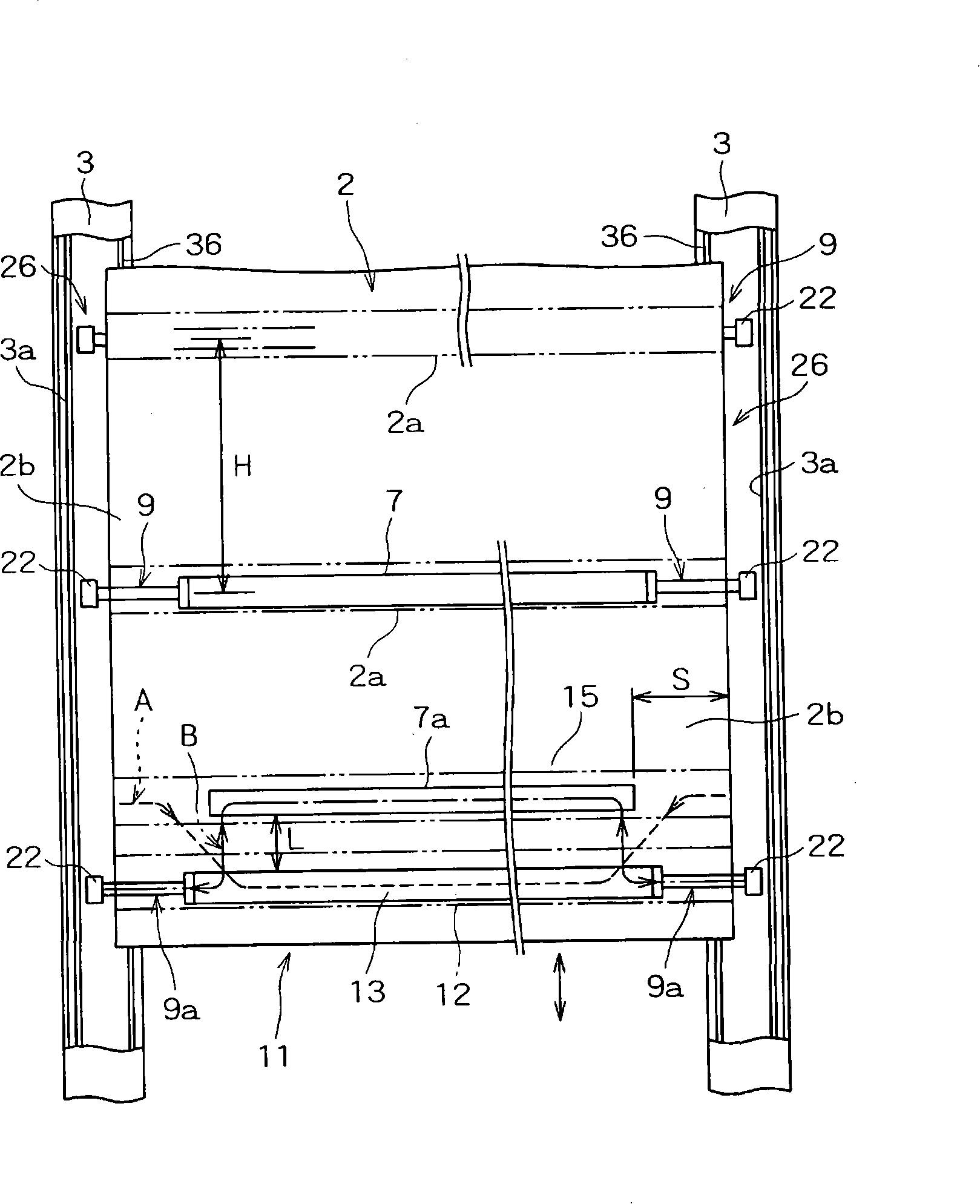

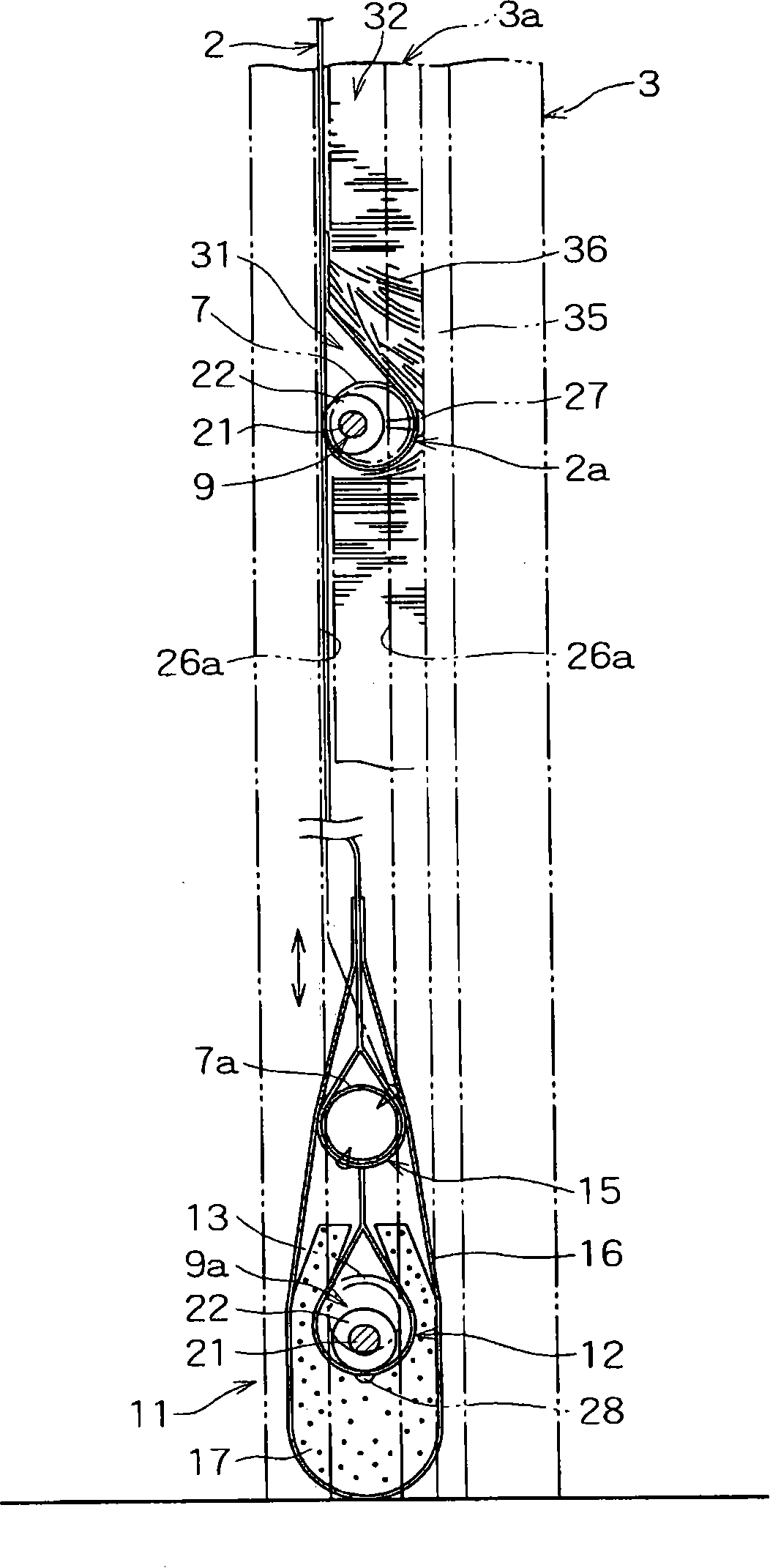

[0027] Next, one embodiment of the present invention shown in the drawings will be described. exist figure 1 , figure 2 Among them, reference numeral 1 is a curtain type rolling door of the present invention, and the entrance and exit are opened and closed by moving a curtain (door) 2 up and down on a door frame erected at an entrance (front opening) of a building or the like. The door frame of the curtain type rolling door 1 is formed into a door-shaped frame by left and right pillars (side frames) 3, 3 and a hollow box-shaped curtain box 4, and the pillars 3, 3 are formed along the building pillars or The wall surface is erected and fixed to form a door installation opening (curtain opening and closing space), and the curtain box 4 is mounted and supported by connecting the upper parts of the pillars 3 and 3 .

[0028] The above-mentioned curtain box 4 is internally provided with a hollow cylindrical take-up drum 5 which is rotatable for taking up and unwinding the curtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com