Heavy type lorry transmission-gear box durable main air valve

A technology for heavy-duty trucks and main air valves, applied to components with teeth, transmission parts, fluid pressure actuators, etc. The air valve is easy to be damaged and other problems, so as to achieve the effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

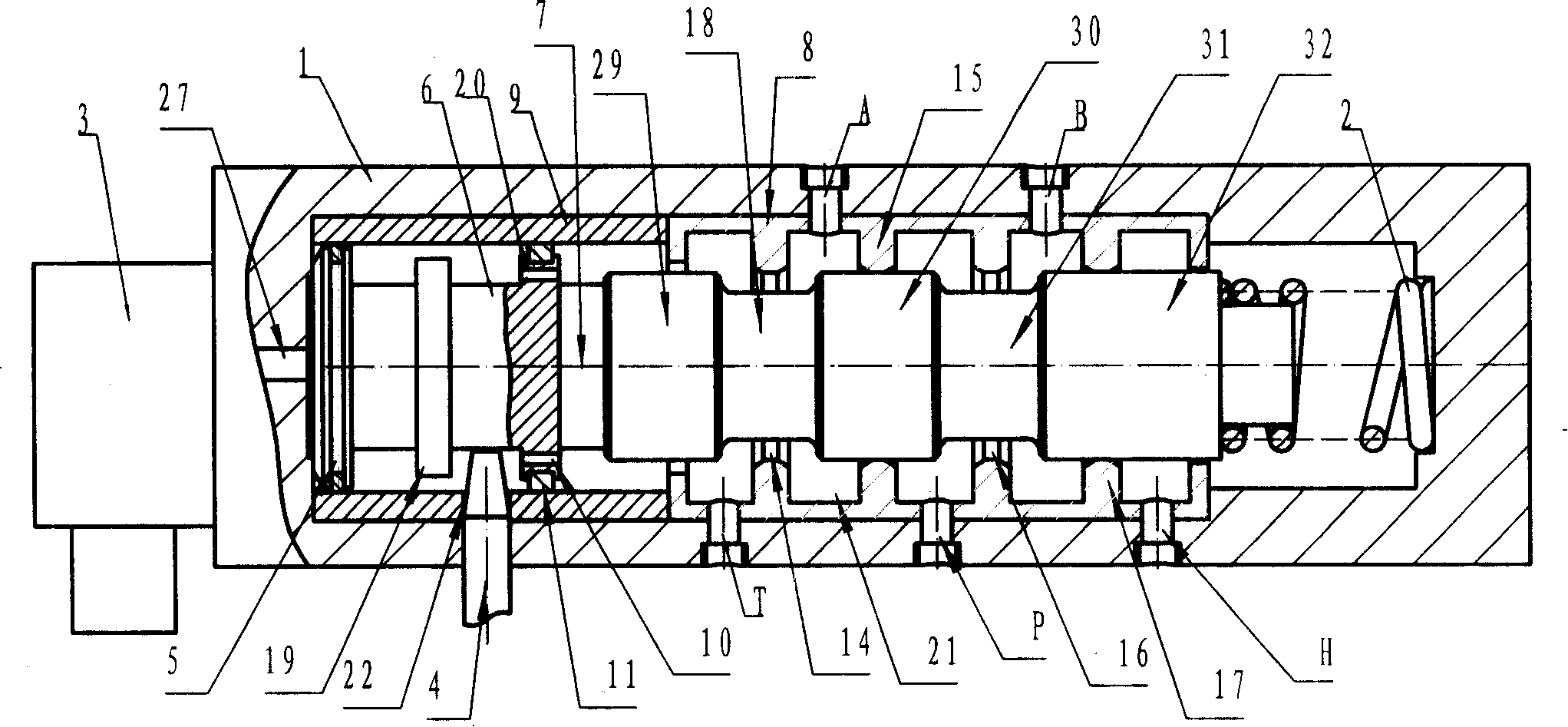

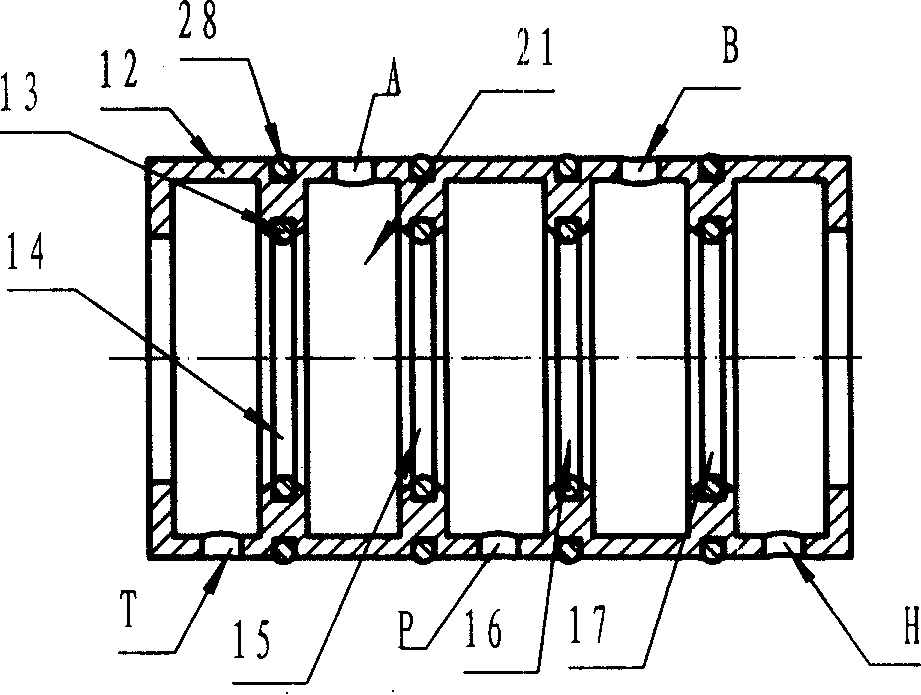

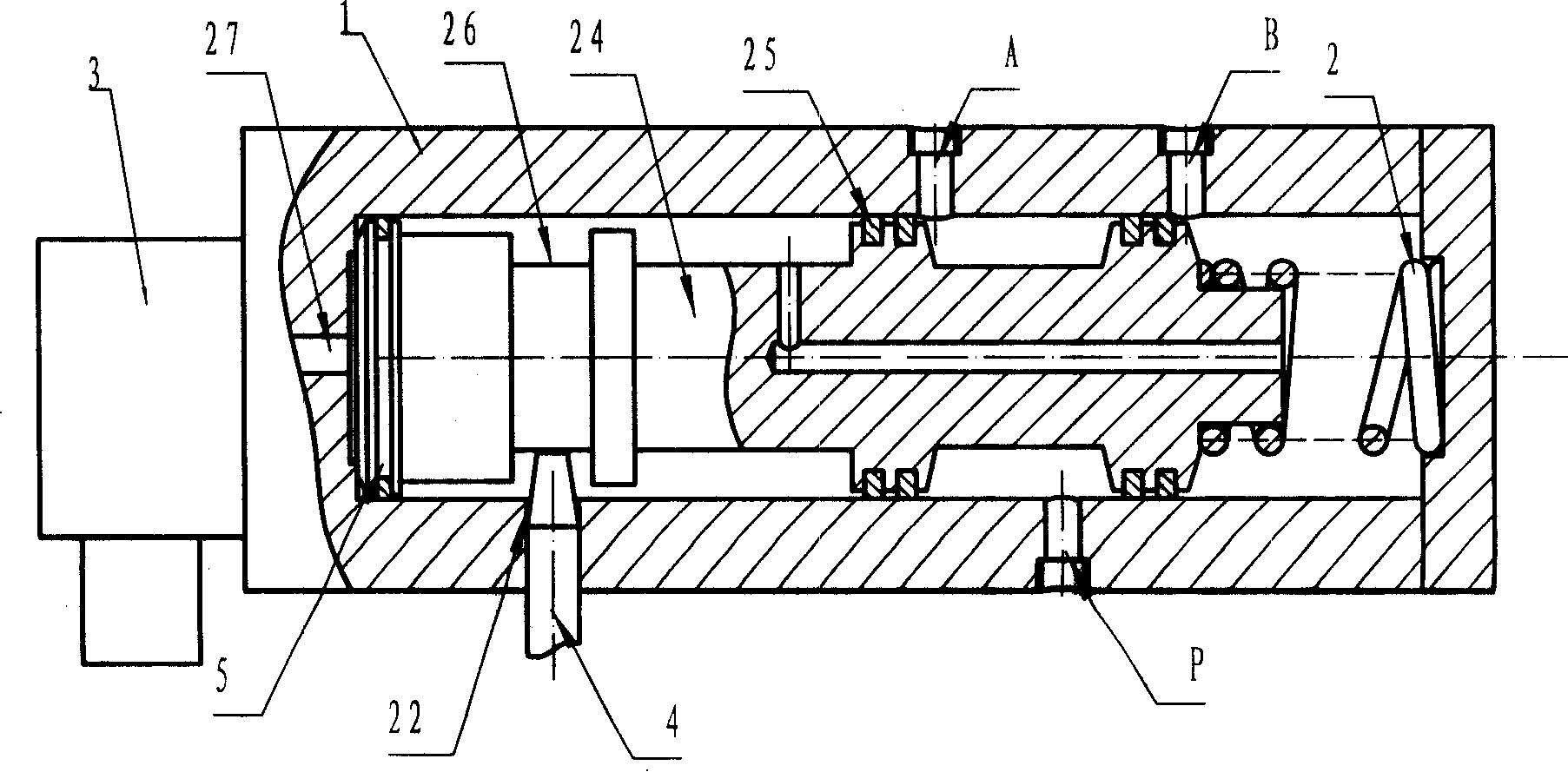

[0008] Specific implementation mode one: refer to figure 1 with figure 2 , the present embodiment is composed of shifting main air valve body 1, spring 2, electromagnetic pilot valve 3, neutral gear pin 4, piston 5, steel retaining ring spool 6, aluminum reversing spool 7, rubber ring valve The seat assembly 8 and the sliding sleeve 9 are composed. The electromagnetic pilot valve 3 is assembled on the left end of the shift main air valve body 1, and the air outlet pipe 27 of the electromagnetic pilot valve 3 communicates with the right end surface of the piston 5. The inside is close to the wall of the inner hole, and the sliding sleeve 9 and the rubber ring valve seat assembly 8 are fixed and assembled sequentially from the left end to the right end, and the piston 5 and the steel ring valve seat assembly 8 are slidingly assembled in the holes of the sliding sleeve 9 and the rubber ring valve seat assembly 8 from left to right. The retaining ring spool 6, the aluminum reve...

specific Embodiment approach 2

[0009] Specific implementation mode two: refer to figure 1 The difference between this embodiment and the first embodiment is that a plastic guide ring 11 is inlaid on the outer circular surface of the right end retaining ring 20 of the steel retaining ring spool 6, and other components and connections are the same as those of the first embodiment. . The plastic guide ring 11 slides along the inner wall of the sliding sleeve 9 and acts as a guide to the steel retaining ring spool 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com