Oil-gas separator provided with conical spiral channel

A technology of oil and gas separator and spiral channel, which is applied in the direction of mechanical equipment, crankcase ventilation, machine/engine, etc. It can solve the problems of poor separation rate of oil mist, oil and gas, need to regularly update filter elements, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

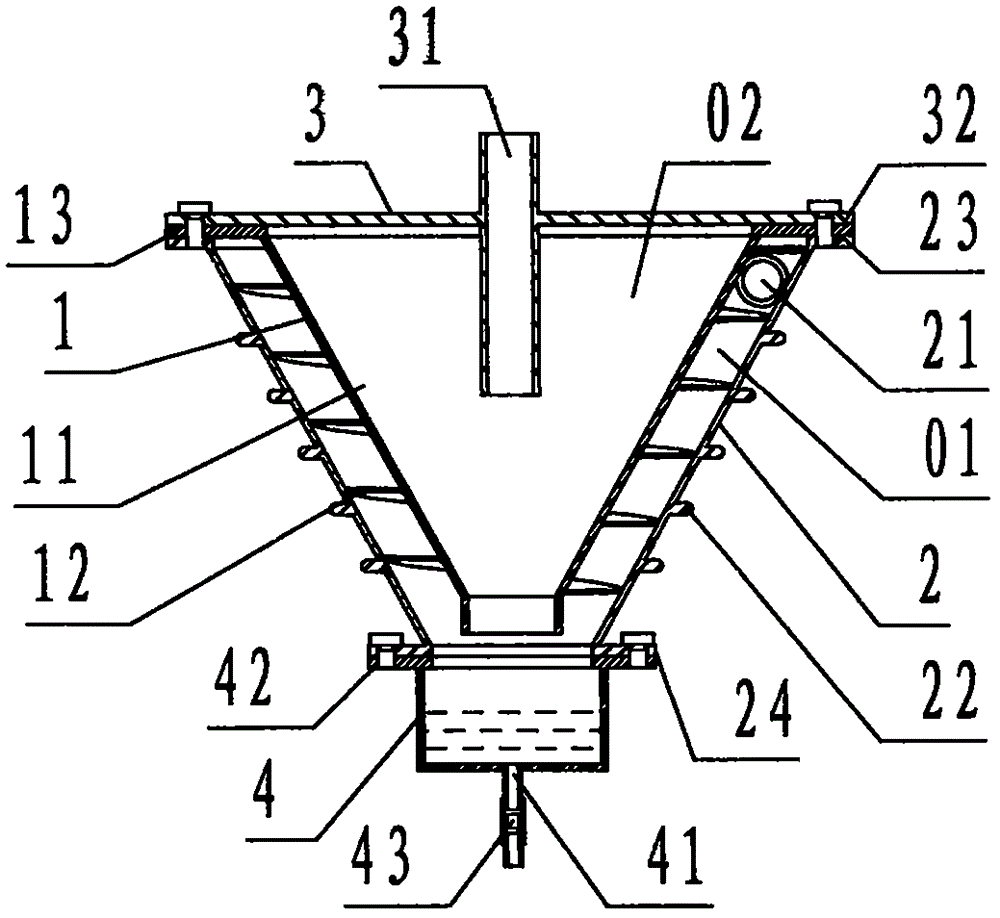

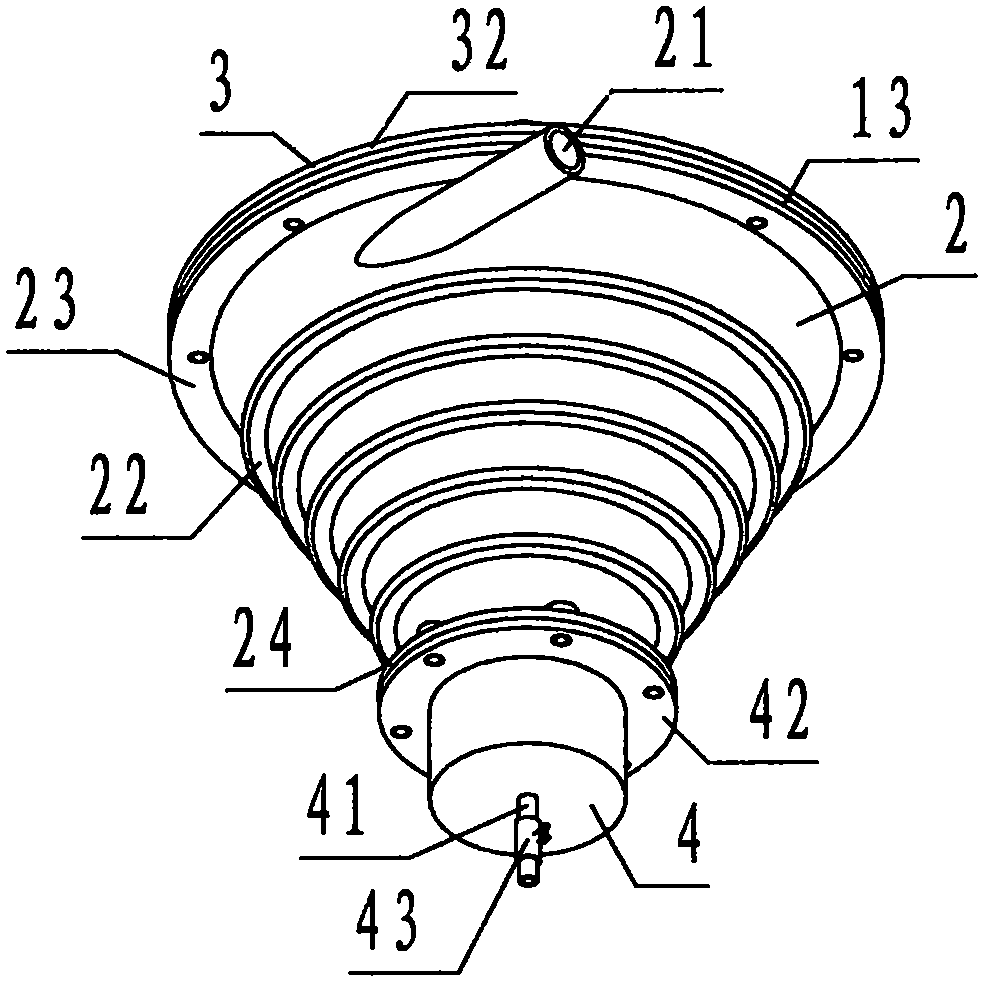

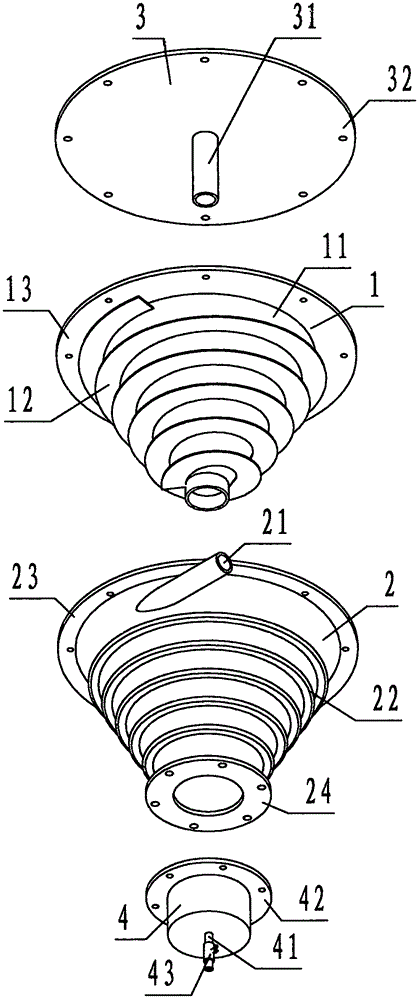

[0025] refer to Figure 1 ~ Figure 4 , a kind of oil-gas separator that is provided with conical spiral channel of the present invention, comprises conical spiral core 1, conical shell 2, upper cover 3, oil collecting bucket 4, wherein: described conical spiral core 1 is made of conical barrel 11, conical The spiral rib 12 and the core flange 13 are formed. The conical cylinder 11 is a hollow and thin-walled aluminum alloy member with a large top and a small bottom, open up and down, and a conical cylindrical shape. The upper edge of the conical cylinder 11 is provided with a horizontal ring. The flange is called the core flange 13, and the core flange 13 is evenly provided with a number of circular through holes for connection called upper connection holes; Convex rib is called conical spiral rib 12, and the pitch of described conical spiral rib 12 is equidistant;

[0026] The conical shell 2 is a hollow and thin-walled aluminum alloy member with a large top and a small bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com