Shape improvement of conversion slice in converter

A commutator segment and commutator technology, applied in the direction of current collectors, rotating current collectors, electrical components, etc., can solve the problems of increased material cost, reduced performance, and small insulation space, and achieve increased strength and electrical insulation performance, Effects of weight reduction and material consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

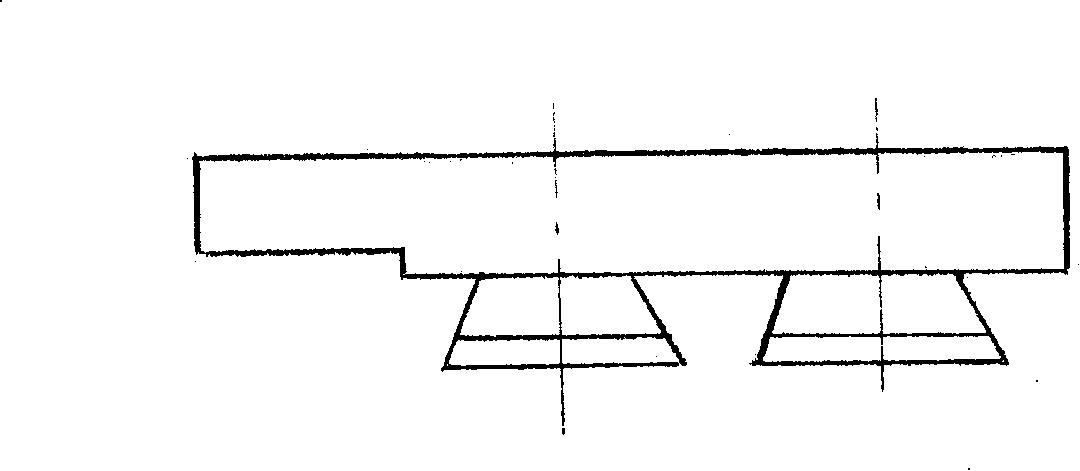

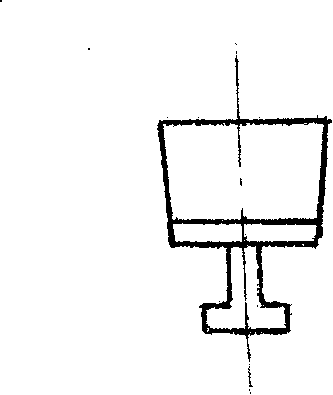

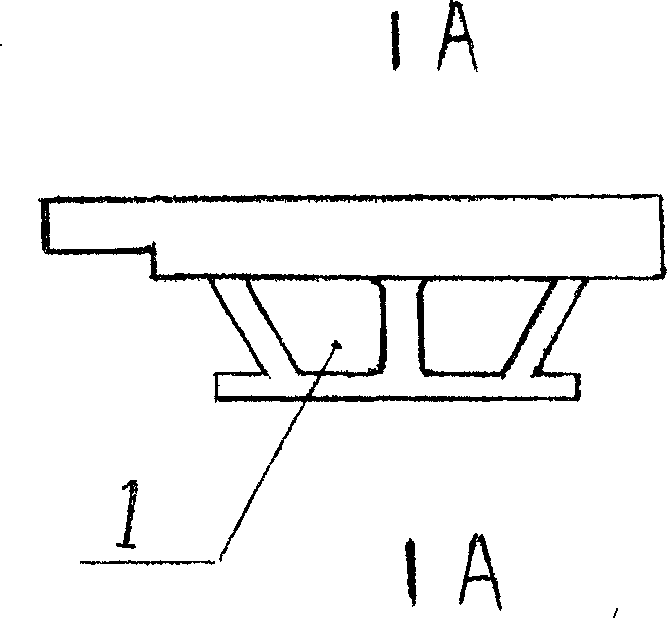

[0013] The accompanying drawings show the embodiment of the present invention and its structure, and the relevant details of the embodiment will be further described below in conjunction with the accompanying drawings. Firstly, the commutator piece is drawn with known technology according to specific specifications to produce a cross-section such as Figure 4 The commutator piece strip shown in the figure, and then the strip is processed by stamping method such as image 3 As shown in the figure, the commutator with two trapezoidal through-holes is then formed by arranging the pieces, inserting the mica pieces, pressing the whole with fillers, turning, milling, stamping and other processes to complete the whole commutator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com