Mouth-moistening compositions, delivery systems containing same and methods of making same

A wetting composition and composition technology, applied to the oral wetting composition, can solve the problem of not providing long-lasting relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

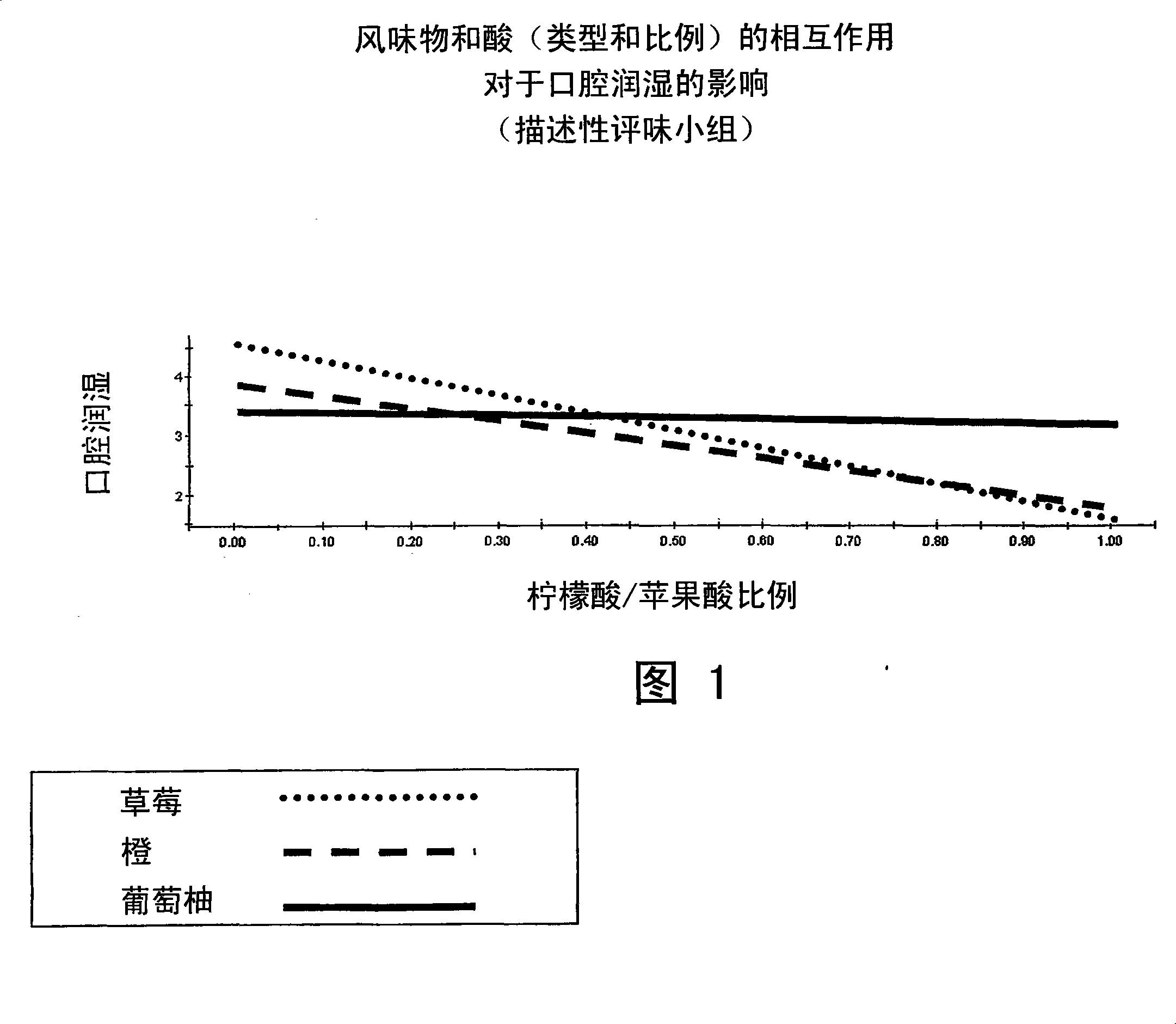

Method used

Image

Examples

preparation example Construction

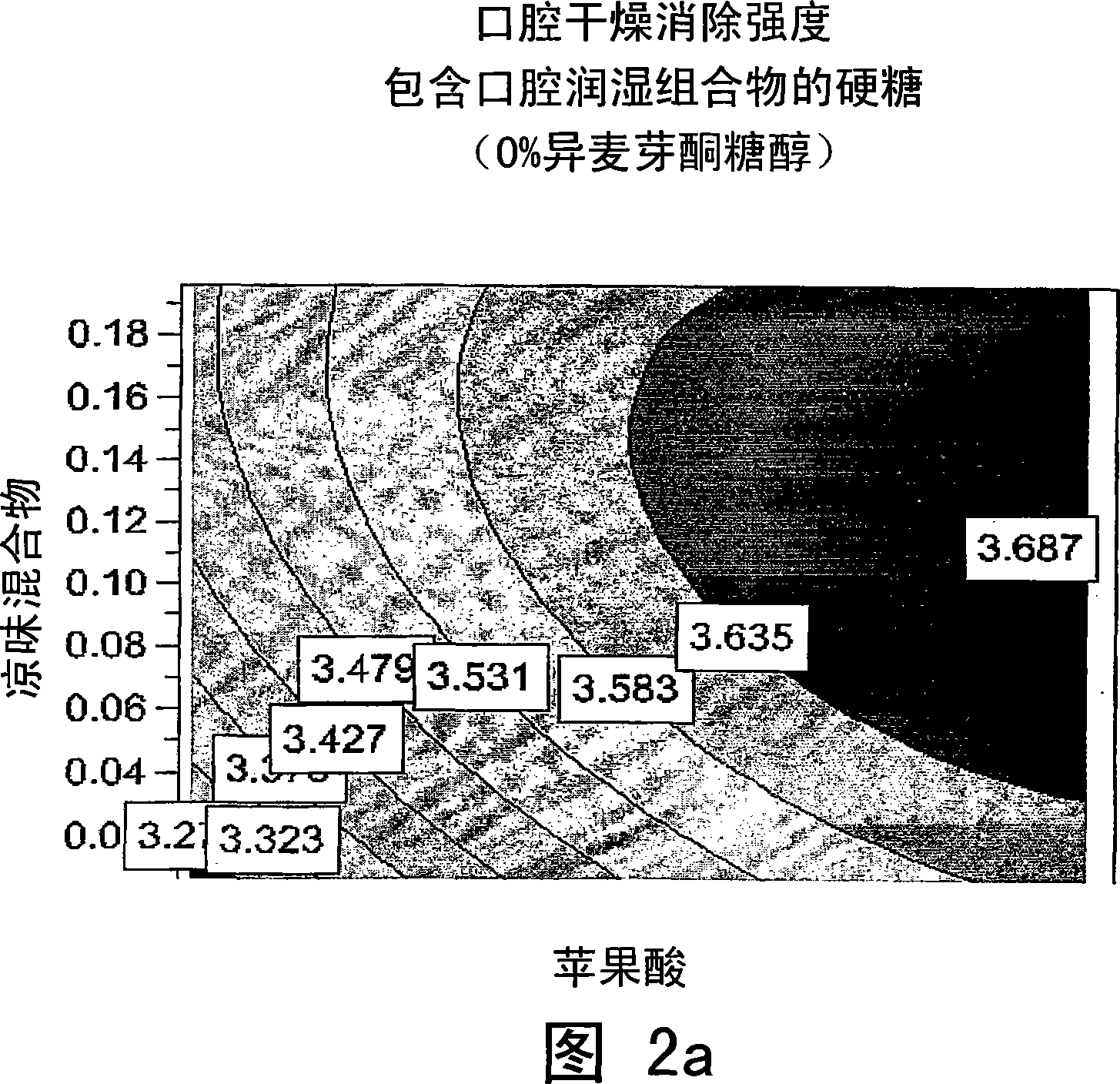

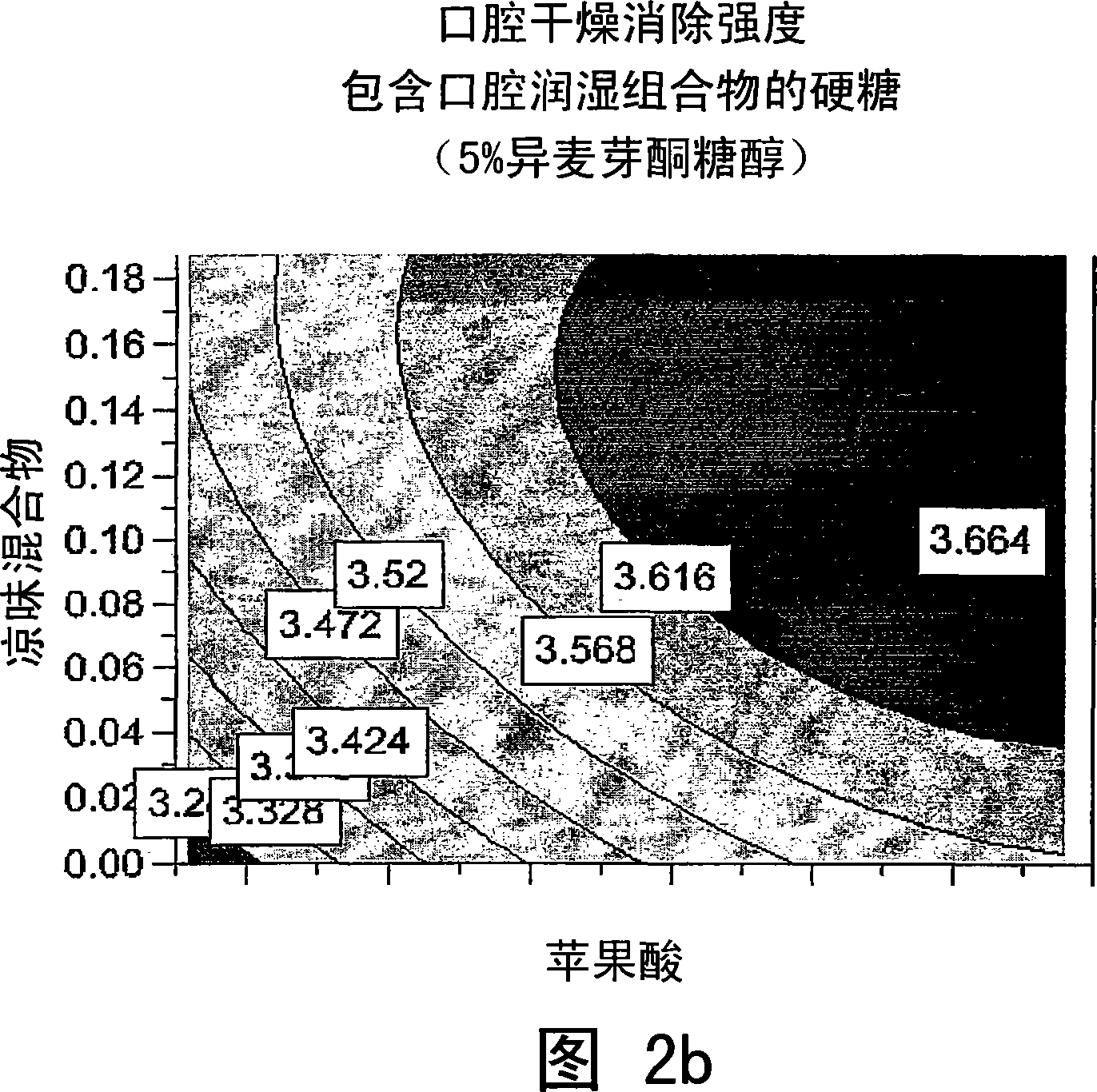

[0098] Some confectionary embodiments are directed to a premix comprising a homogeneous dry blend of sugar and a sweetening reducing agent according to the method of preparation described above. The premix may include a food grade acid composition and a cooling agent as described above. Other embodiments are directed to compositions comprising a boiled amorphous base comprising sugar and a sweetness reducing agent, a food grade acid composition and a cooling agent.

[0099] Still other confectionary embodiments relate to divisible, or, alternatively, molded confectionery masses. As noted above, the divisible confectionery mass may include a mouth-moistening composition, a flavoring agent, and, optionally, a carrier. The moldable confectionery mass may include a mouth-moistening composition, which may be a molding blend of a sweetener composition, a food-grade acid composition, and a cooling agent. The molded confectionery mass may also include flavoring agents, and, optional...

Embodiment 1

1.23

1 WS-23 and others from International Flavors & Fragrance, Inc.

(IFF) available proprietary cooling agent

[0118] The components listed in Table 1 above were combined to form a mouth-moistening composition. The mouth-moistening compositions are incorporated into a variety of different sugar-based comestibles.

Embodiment 2

0.40

1 WS-23 and other proprietary cooling agents available from IFF

[0119] Hard boiled candies were prepared according to the recipe in Table 2 above.

[0120] A 50% aqueous preparation of isomalt was thoroughly mixed and heated to 90°C. The homogeneous solution was added to the sugar / glucose mixture and the whole batch was heated to 146°C. The batch was placed on a cooling table where color, malic acid, cooling agent and flavor were added. The batch is kneaded and the roll candies are dropped into pieces of the desired weight and size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com