Automatic detection method for printed product four-color register partial difference

A registration deviation and automatic detection technology, applied in the field of automatic detection of four-color registration deviation of printed products, can solve the problems of operator fatigue, difficulty, poor efficiency, etc., to achieve the improvement of automation degree and adjustment speed, easy operation and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

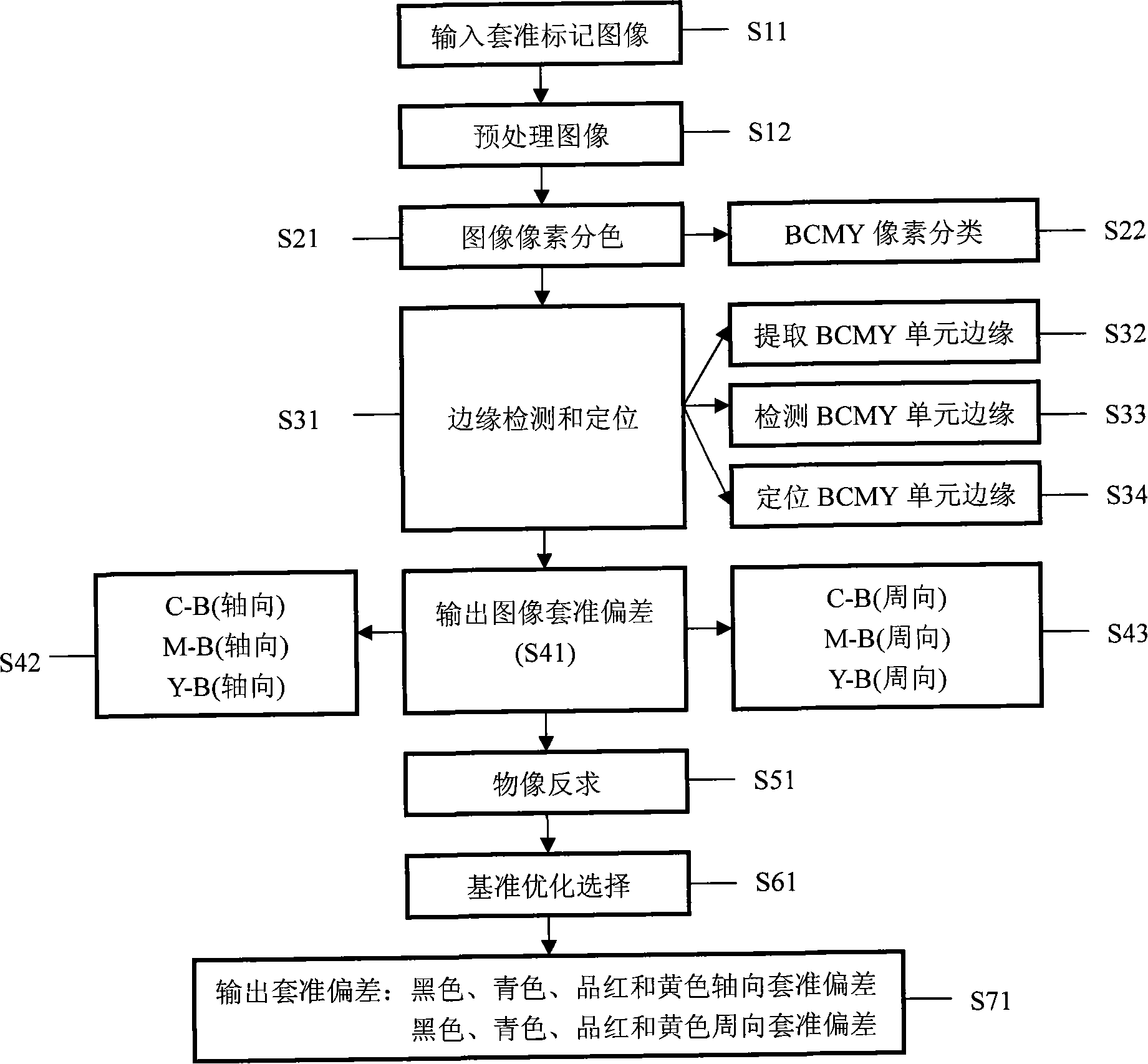

[0070] The present invention is described in further detail now in conjunction with accompanying drawing. figure 1 A flowchart showing the automatic detection method for four-color registration deviation of printed products involved in the present invention, as shown in the figure, the automatic detection method for four-color registration deviation of printed products includes the following steps:

[0071] 1. Preprocessing the registration mark image

[0072] The registration mark image S11 is input to the computer, and the color image vector median filter method is used for filtering to obtain the filtered color image IA. Then use the following method to segment the target marker and the image background for the color image:

[0073] (1) For all pixels in the entire color image IA, convert the image IA into a grayscale image IB. The conversion method is: the red, green, and blue gray values of the pixels in the gray image IB are equal, and equal to the summed average of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com