Method for manufacturing nano-oxide powder

A nano-oxide and powder technology, applied in the field of nano-oxide powder preparation, can solve the problems of a large amount of deionized water, serious environmental pollution, long production process, etc., and achieve the effects of good dispersibility, high purity and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

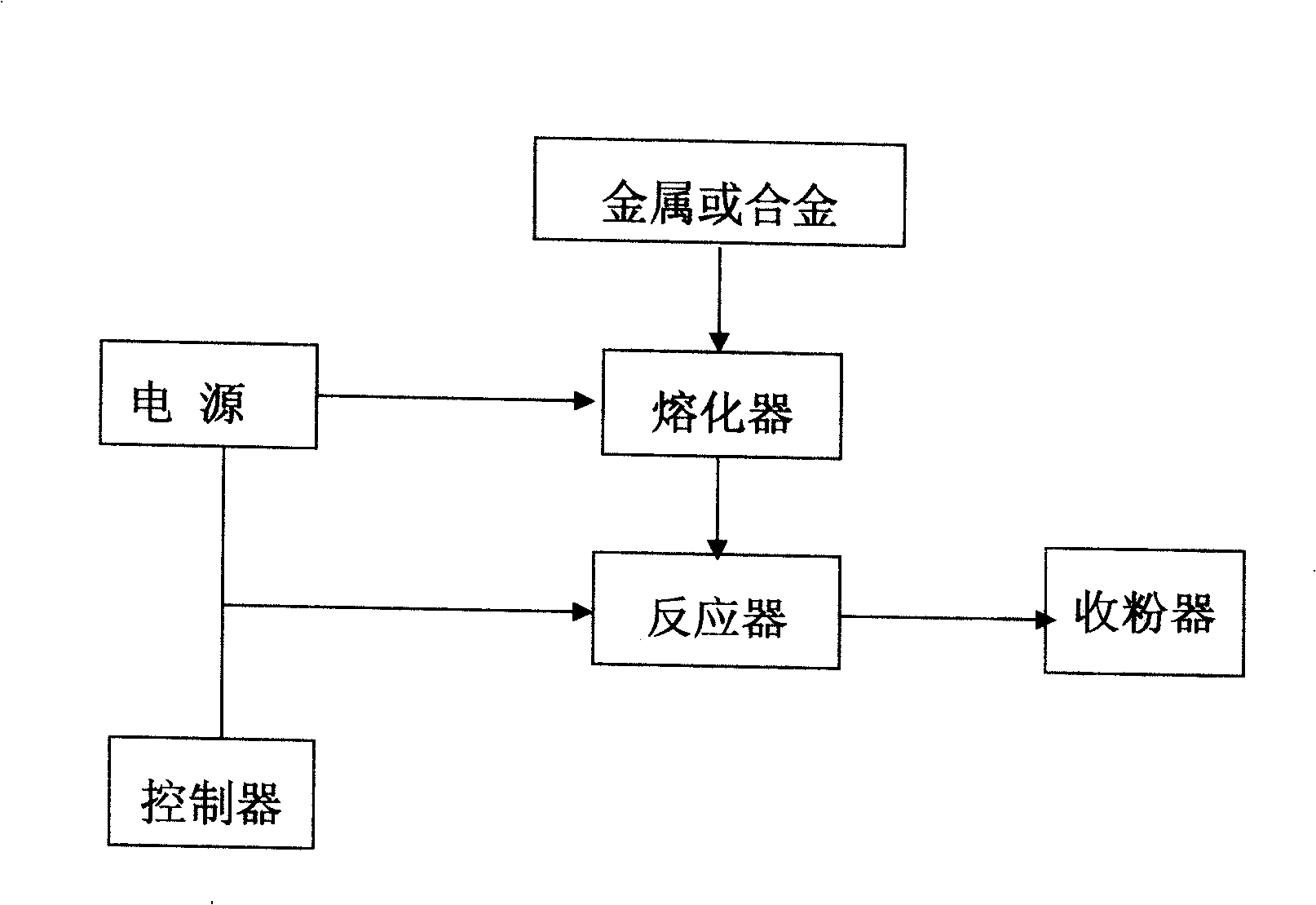

Method used

Image

Examples

specific Embodiment approach 2

[0036] Nano In 2 o 3 preparation

[0037] 1. Indium ingot with a purity of 99.99%.

[0038] 2. Melt the indium ingot and heat it to 200°C with electricity.

[0039] 3. Press the molten indium into the reactor. A mixed gas of nitrogen and oxygen was introduced into the reactor.

[0040] 4. Apply a voltage of 50-1000V and a current of 5-2000A to the electrodes and the reactor.

[0041] 5. Turn on the powder collection system.

[0042] The indicators of the products produced are shown in Table 2.

[0043] Table 2 Nano In 2 o 3 Product Specifications

[0044]

specific Embodiment approach 3

[0045] Preparation of Nano-ITO

[0046] 1. Press In 2 o 3 :SnO 2 =9:1 ratio, converted into the weight of indium and tin.

[0047] 2. Melt indium tin to make alloy.

[0048] 3. Put the alloy into the melter and heat it to about 220°C with electricity.

[0049] 4. Press the molten indium-zinc alloy into the reactor.

[0050] 5. Apply voltage to the reactor, the voltage is 50-1000V, and the current is 50-1000A. Nitrox mixed gas into the reactor

[0051] 6. Turn on the powder collecting system.

[0052] The indicators of the products produced are shown in Table 3.

[0053] Table 3 Nano-ITO product technical indicators

[0054]

specific Embodiment approach 4

[0055] Nano IZO powder

[0056] 1. Press indium zinc into In 2 o 3 : The ratio of ZnO=93:7 is converted into the weight of indium and zinc by weight and added to the melting furnace.

[0057] 2. Heat the melter to about 620°C to melt the indium-zinc alloy.

[0058] 3. Press the molten indium-zinc alloy into the reactor.

[0059] 4. Apply voltage to the reactor, the voltage is 50-1000V, and the current is 50-1000A. Pure oxygen was introduced into the reactor.

[0060] 5. Turn on the powder collection system.

[0061] Powder product index see Table 4

[0062] Table 4 Nano-IZO product technical indicators

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap