Labor saving machine

A force machine and lever technology, applied in the field of labor-saving machines, can solve problems such as inability to save labor, and achieve the effects of energy saving, convenient matching and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

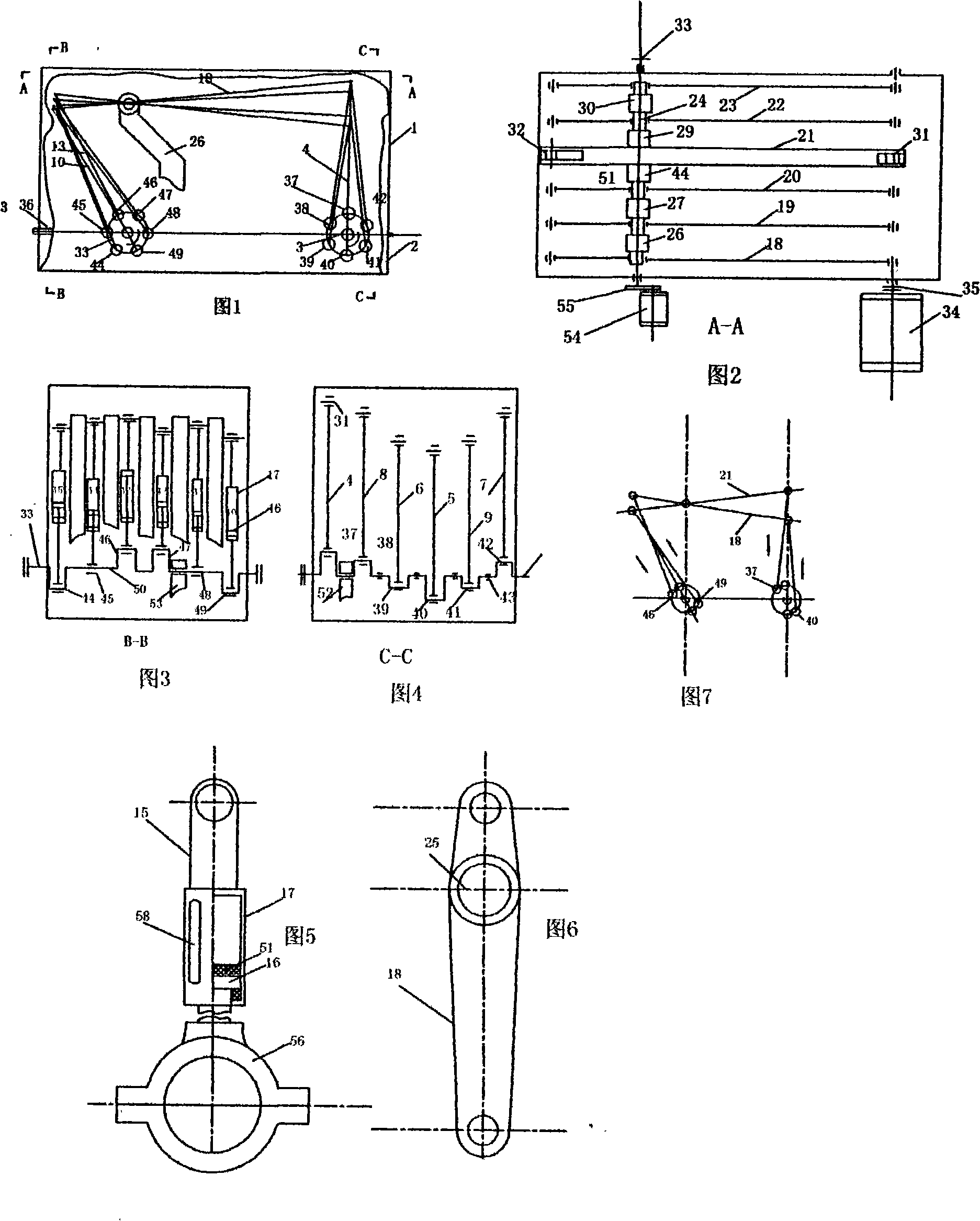

[0016] In Figure 1, the upper box ① and the lower box ② have fasteners Connection, front crankshaft ③ rear crankshaft Each end connected to the lower casing ② can also be a bearing with a bearing bush, and the upper casing ① is pressed down, and the front crankshaft ③ crank (37-42) is slidingly connected with the connecting rod (4-9), and the other end of the connecting rod is connected with a pin axis , and the long end of the lever (18-23) is slidingly connected, and the center hole of the lever is set at the position where the mechanical benefit of each lever (18-23) is greater than 1 The lower part of the lever bracket (26-30) is connected with the lower box body ②, and the upper part has a perforation, and the lever shaft There are fasteners through the lever (18-23) and bracket (26-30) lever shaft fixed, lever (18-23) on lever shaft upper slide, rear crankshaft Crank (44-49) and one end of piston type rear connecting rod (10-15) use split bearing bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com