Cursor type non-contact plastic wheel or tumbling cylinder diameter measuring apparatus and measuring system using the same

A non-contact, roller diameter technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost and inability to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

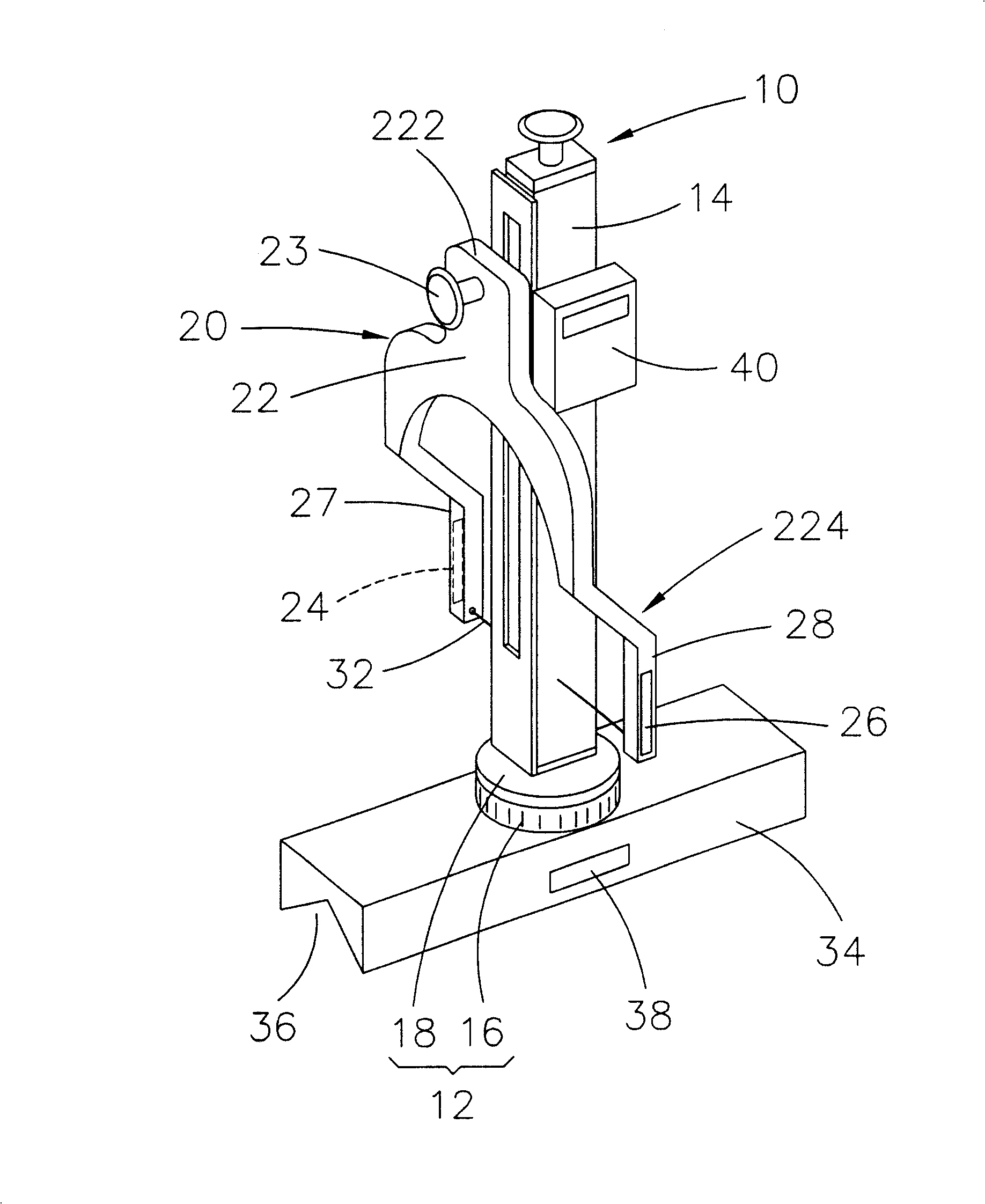

[0055] See figure 1 In the figure, it is disclosed that the measuring device 10 includes a base 12, a guide rail 14, and a measuring component 20. The base 12 includes a fixed disk 16 and a rotating disk 18, wherein the rotating disk 18 is rotatably assembled on the fixed disk 16. The guide rail 14 is assembled on the rotating disk 18 of the base 12.

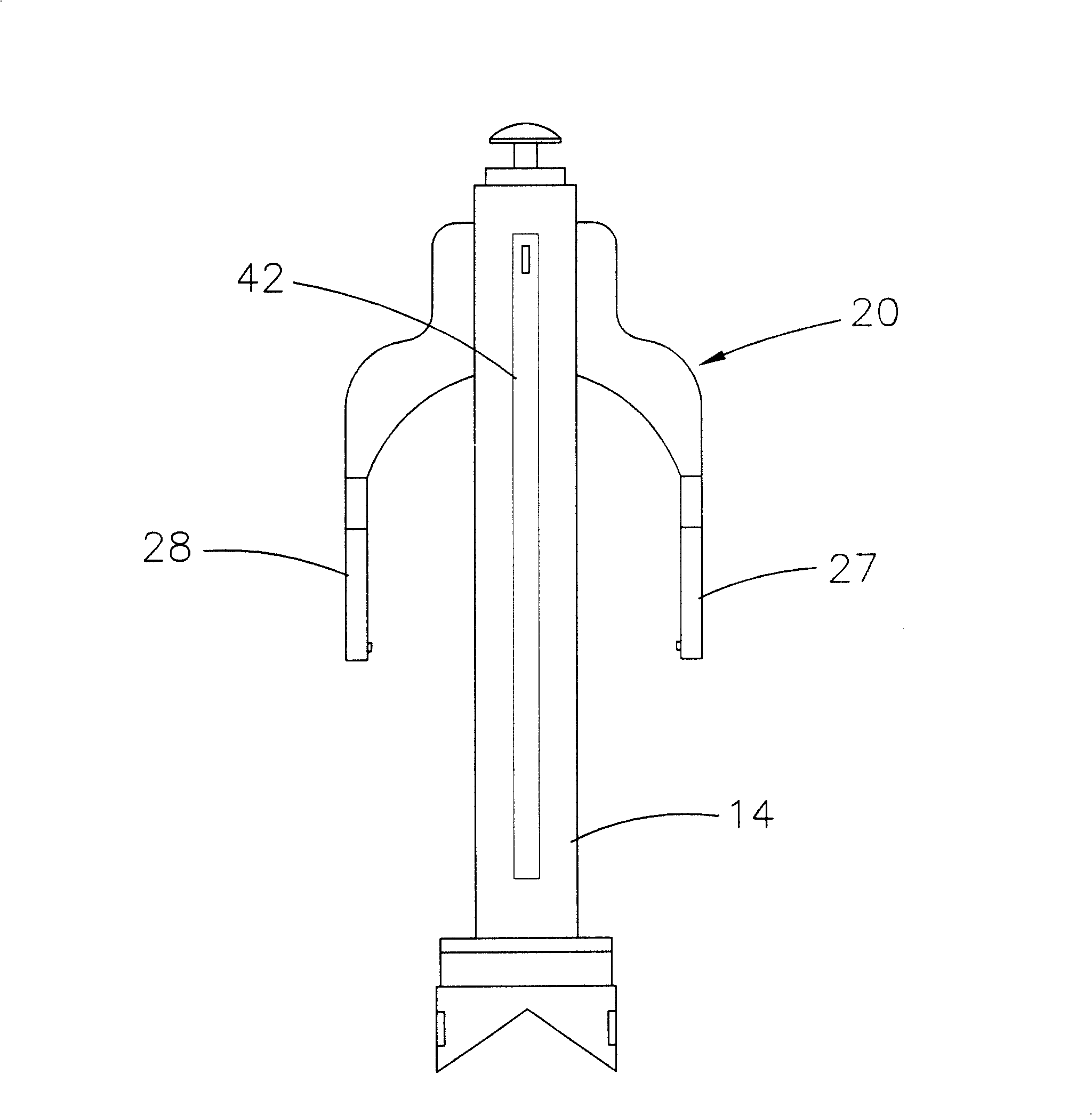

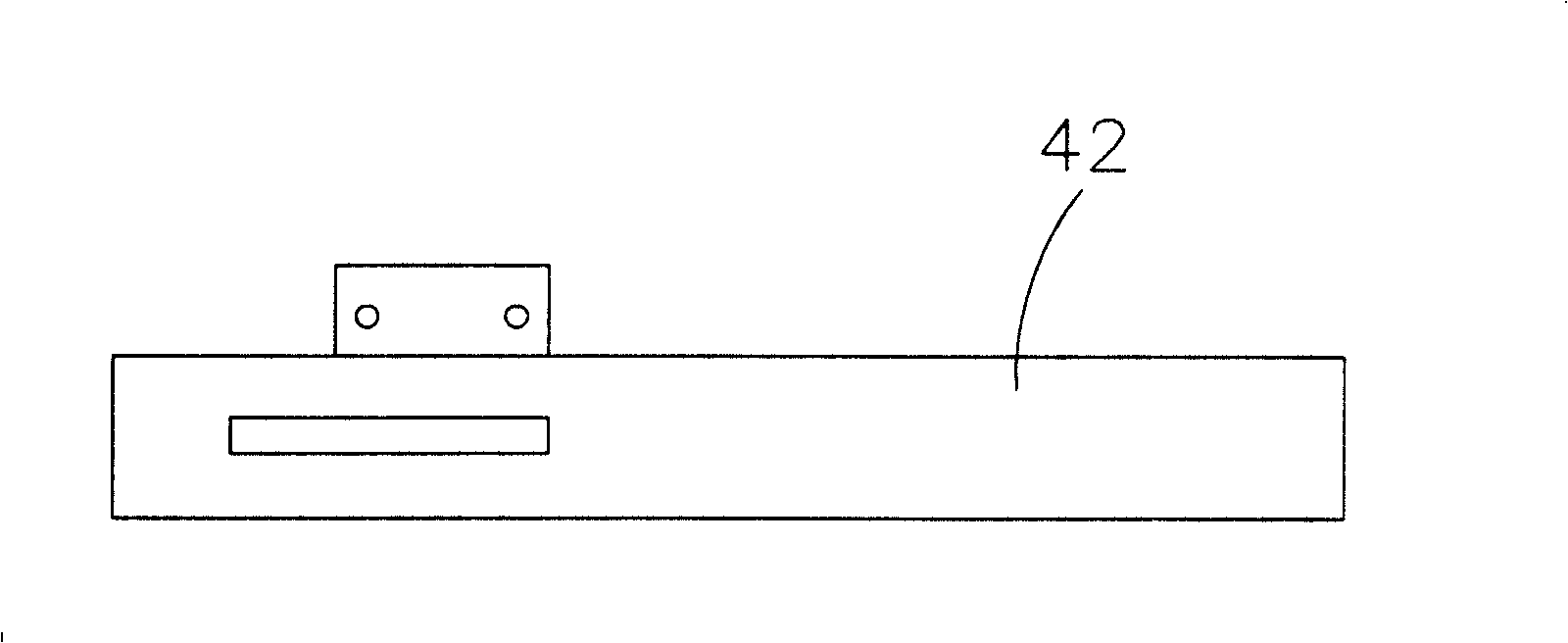

[0056] The measuring component 20 includes a fixing frame 22 and two light emitting / receiving components 24 and 26. The fixing frame 22 has two ends. The first end 222 is set on the guide rail 14 in combination with a handle 23. The second end 224 is a free end and forms two arm portions 27 and 28. The two arm portions 27 and 28 Opposite and an opening is formed between the two arm portions 27 and 28. The two light emitting / receiving components 24 and 26 are assembled on the two arm portions 27 and 28 respectively, and the two light emitting / receiving components 24 and 26 perform light emission and light reception respectively to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com