Inspection apparatus for pattern

A technology for inspecting devices and patterns, applied in measuring devices, electronic circuit testing, optics, etc., can solve the problems of conductive pattern damage, dust generation, etc., and achieve the effect of improving inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

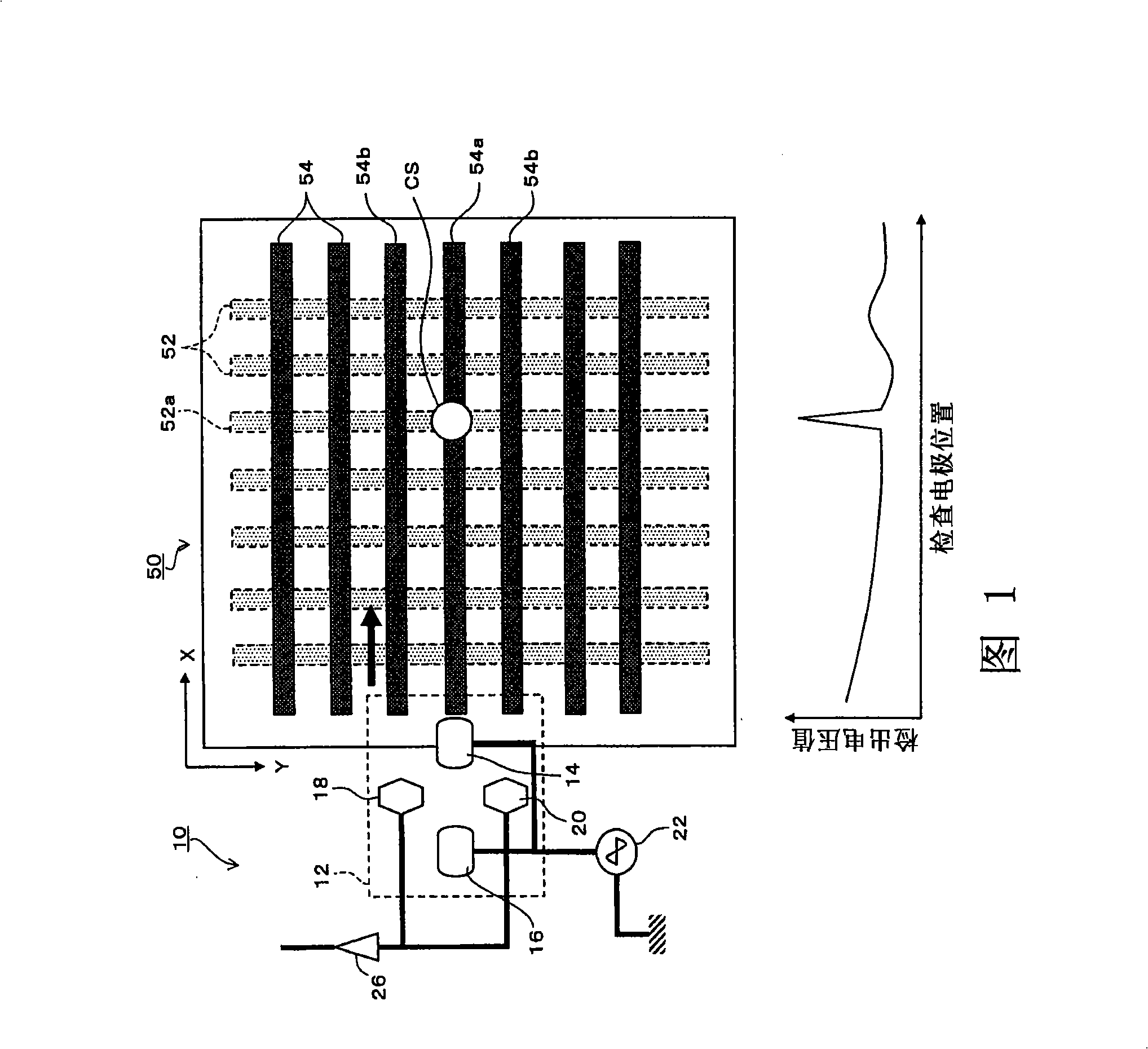

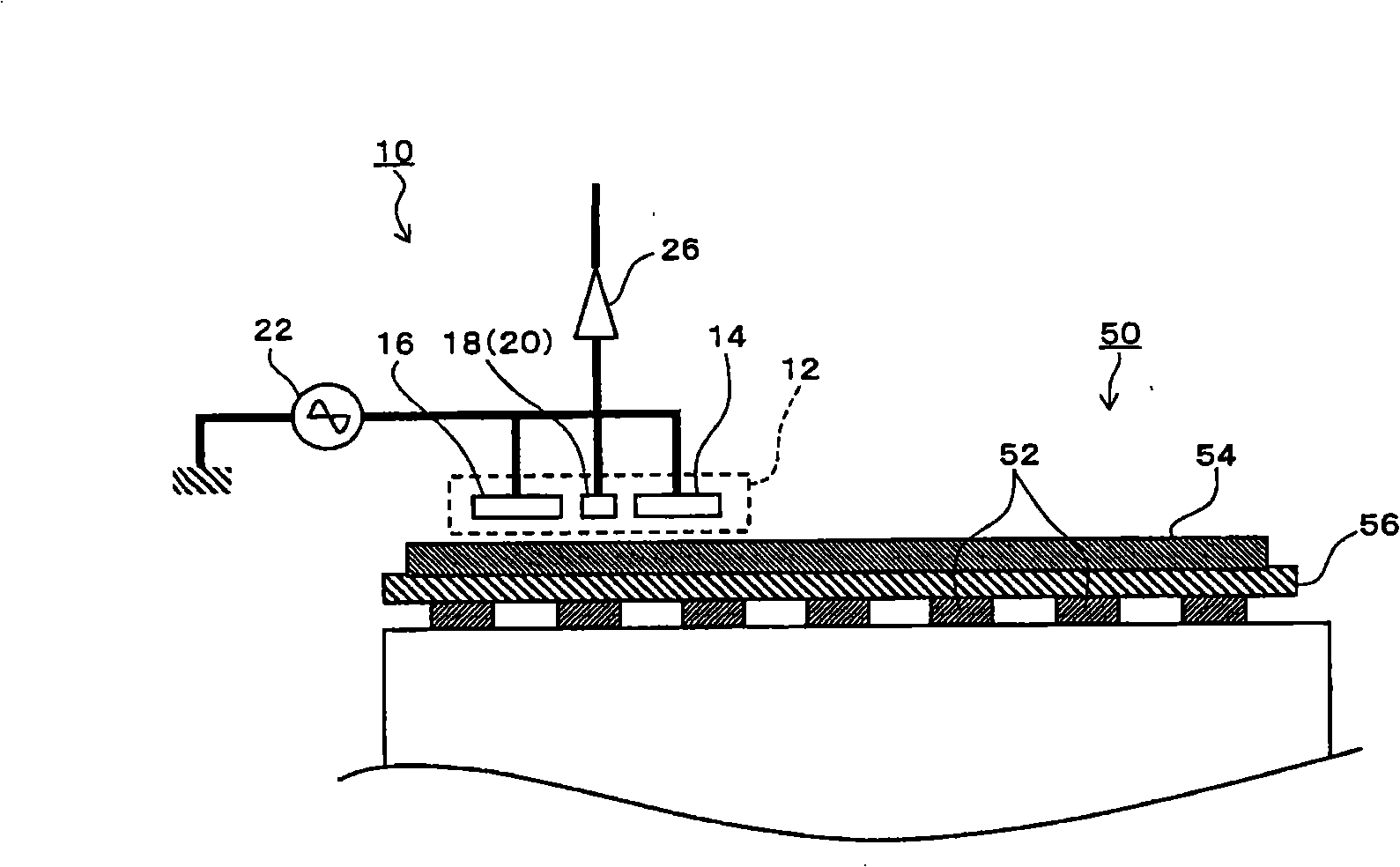

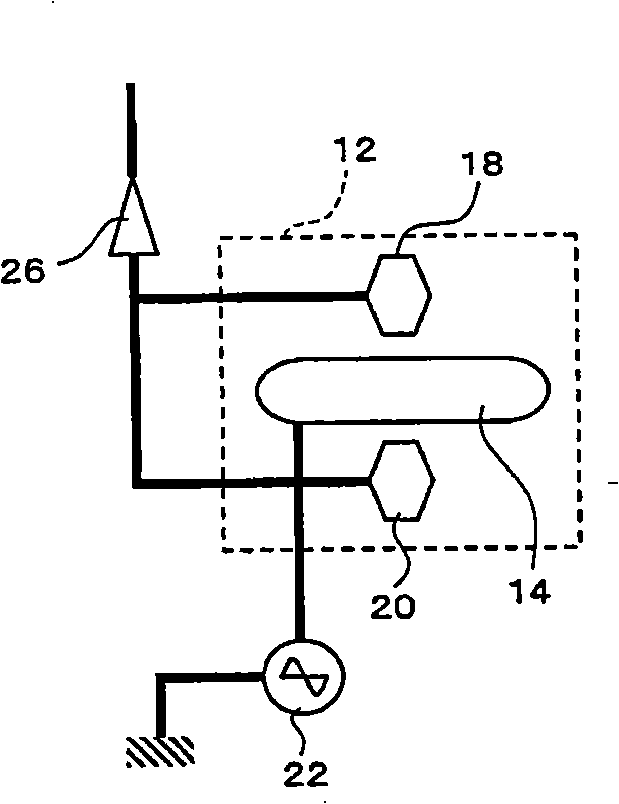

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following description, a conductive pattern arranged in a plurality of columns on a glass substrate for use in a liquid crystal panel or the like will be inspected. However, conductive patterns used in devices other than liquid crystal panels may also be inspected as long as they are conductive patterns arranged in multiple columns.

[0043] FIG. 1 is a schematic plan view of a pattern inspection device 10 according to a first embodiment of the present invention. in addition, figure 2 is its profile side view. The pattern inspection device 10 is a pattern inspection device suitable for judging the position of the cross-short circuit. Here, before describing the pattern inspection device in detail, a brief description of the cross-short circuit

[0044] A general liquid crystal panel 50 etc. is formed by stacking a first layer in which conductive patterns called...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com