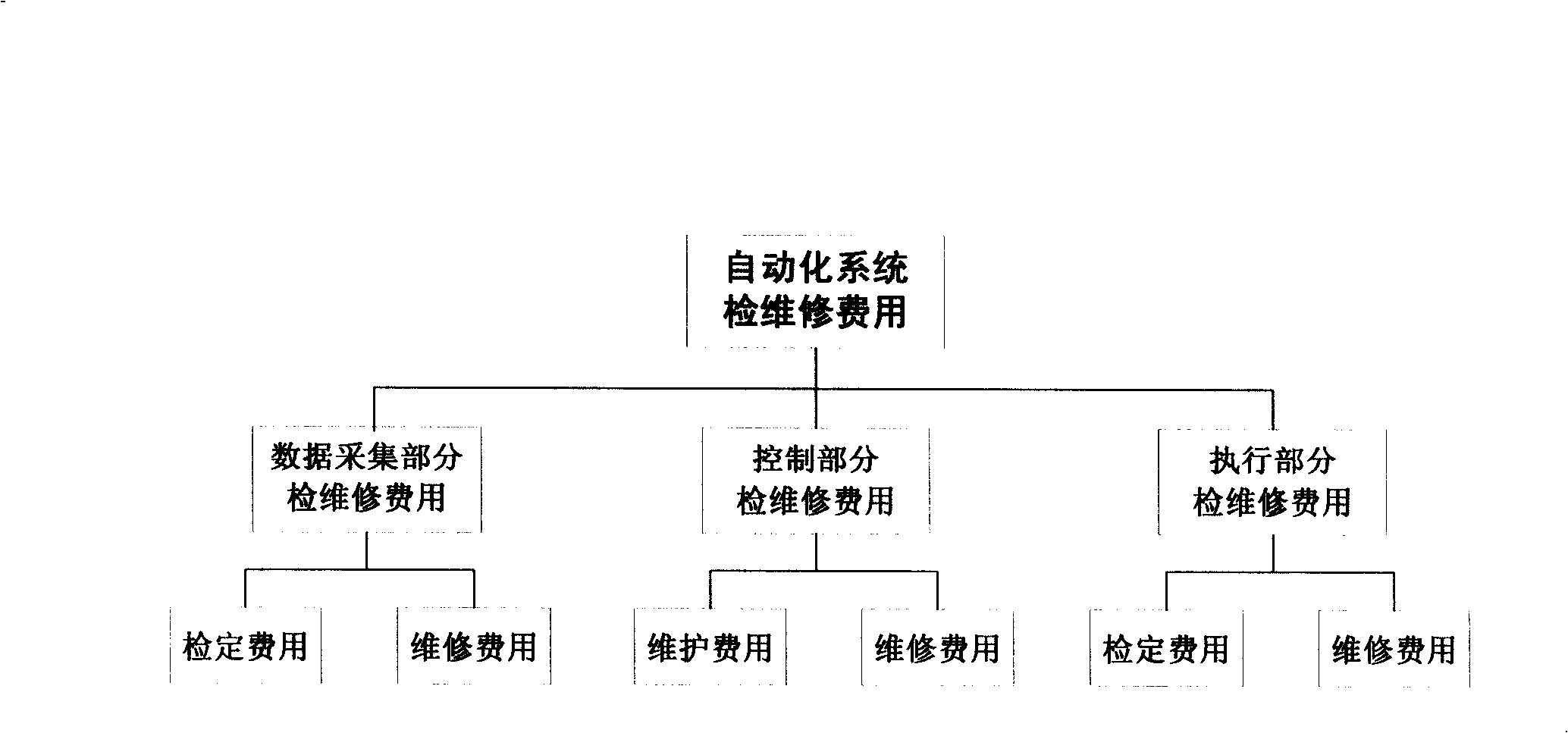

Automatization system maintenance and charge reckoning method

An automation system and maintenance cost technology, applied in the drilling automatic control system, calculation, earthwork drilling, etc., can solve the lack of standardization and planning of automation system inspection and maintenance, lack of standards for maintenance cost investment, oil and gas field facilities and equipment Aging and other problems, to achieve the effect of eliminating adverse effects and environmental pollution, eliminating hidden troubles, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (1) Taking the general automation system used in oil and gas fields as an example, describe the inspection and maintenance methods in detail:

[0023] 1 Maintenance content and cycle

[0024] 1.1 Maintenance content and cycle of data acquisition system

[0025] 1.1.1 Maintenance content of integrated temperature transmitter

[0026] a) Appearance inspection of temperature transmitter; b) Indication value verification; c) Zero point time drift verification; d) Temperature drift characteristic verification; e) Stability verification; , generally no more than one year.

[0027] 1.1.2 Maintenance content and cycle of pressure transmitter

[0028] a) Appearance inspection; b) Sealing inspection; c) Verification of basic error; d) Verification of return error; e) Verification of static pressure influence; f) Electrical performance verification of electric transmitter; g) Pneumatic transmitter The verification of the influence of the air source pressure change; h) the veri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com