Absorbent articles comprising surface cross-linked superabsorbent polymer particles made by a method using vacuum ultraviolet radiation

A technology for superabsorbent polymers and absorbent products, applied in absorbent pads, bandages, medical science, etc., can solve problems such as difficulty in obtaining superabsorbent polymer particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

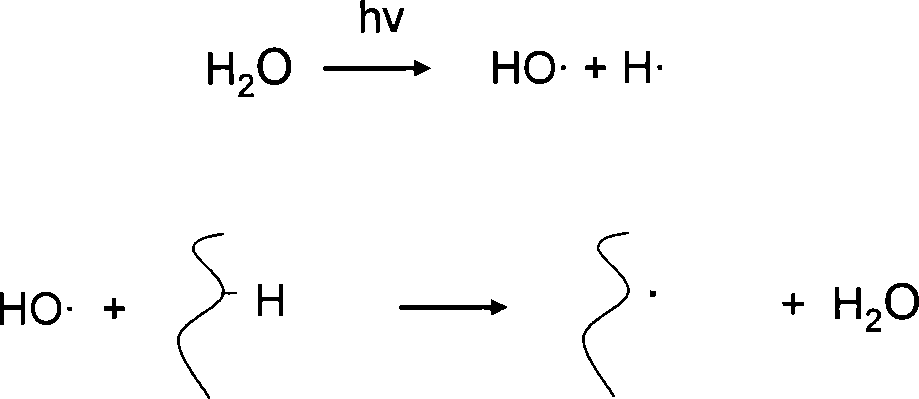

Method used

Image

Examples

Embodiment

[0216] Base Polymer:

[0217] The water-swellable polymer described in Example 1.2 of WO 2005 / 014066 A1 entitled "Absorbent articles comprising coated water-swellable material" and filed on February 17, 2005 was used as matrix polymer. However, the amount of MBAA has to be regularly adjusted accordingly in order to obtain superabsorbent polymer particles having a centrifuge retention capacity value of 37.5 g / g as in the examples. It should be noted that the centrifuge retention capacity values can in principle be adjusted in the same way as the CCRC method described in Example 1.2 of WO 2005 / 014066 A1.

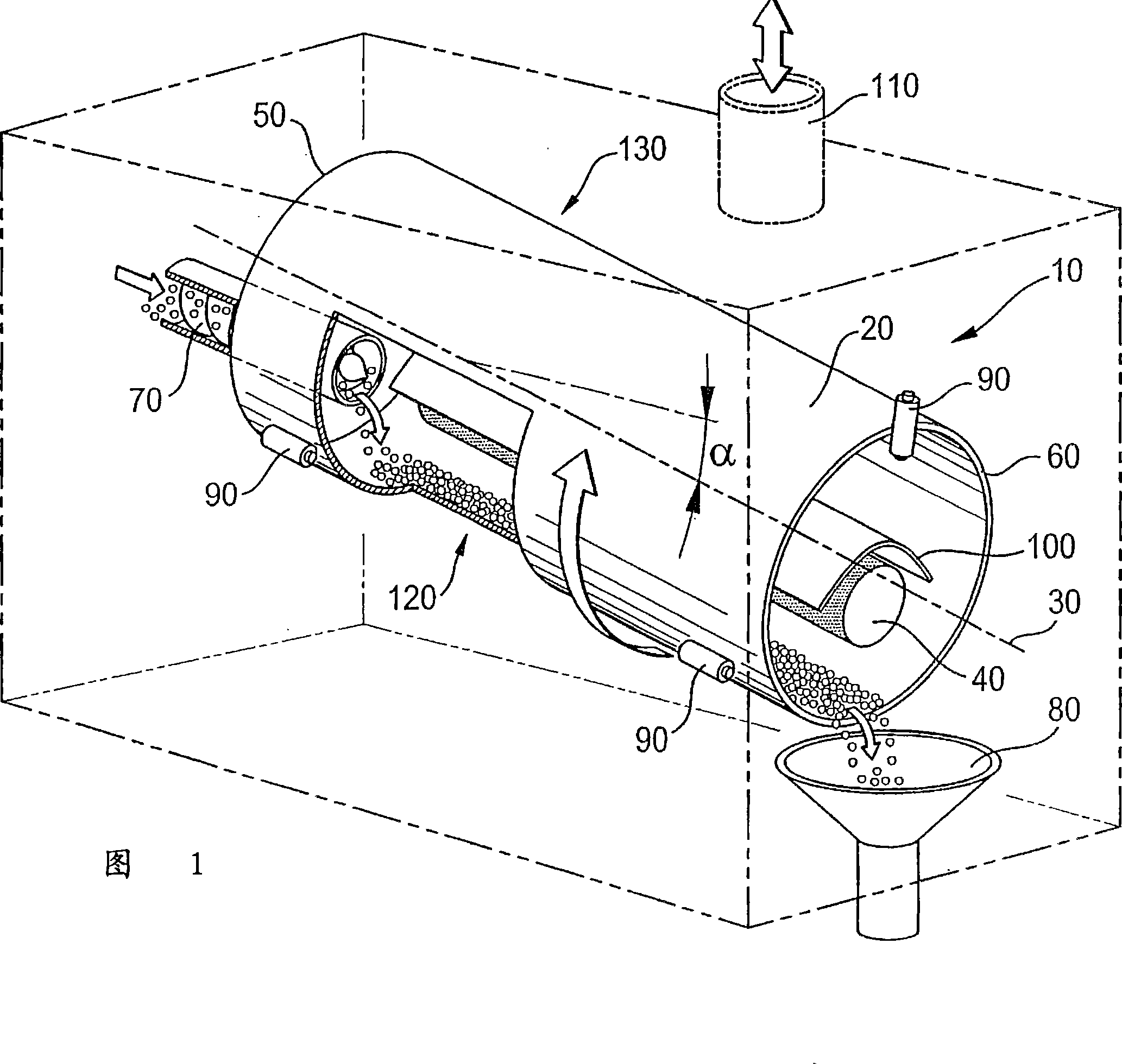

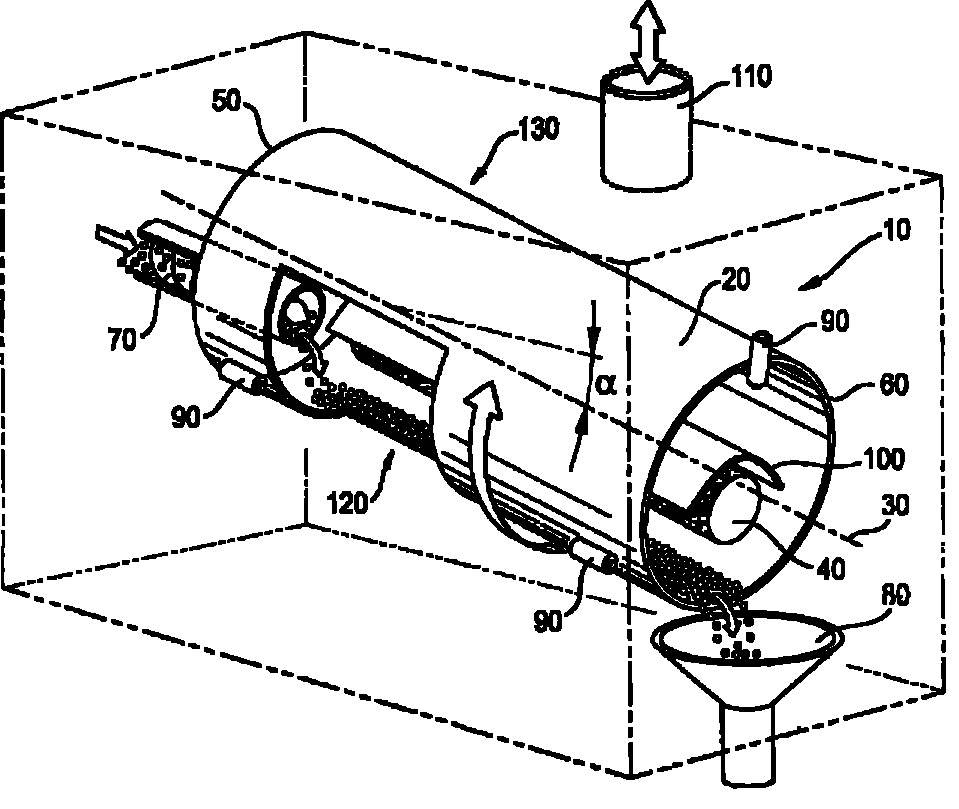

[0218] The drum reactor used in the examples has a length of 40 cm and a diameter of 11 cm. The drum is made of glass, wherein the inner surface of the drum is slightly roughened. The roughness is adjusted to provide a one minute residence time of the superabsorbent polymer particles in the drum. The inner surface of the drum has an equally distributed roughness, ie all...

Embodiment 2

[0225] The superabsorbent polymer particles in Example 2 were fed sequentially through the drum 5 times, whereby all the superabsorbent polymer particles in the sample were re-fed into the drum immediately after they had left the drum . Thus, the superabsorbent polymer particles in Example 2 were irradiated for a total of five minutes.

[0226] The centrifuge retention capacity and saline flow conductivity values of the initial superabsorbent polymer particles (ie, superabsorbent polymer particles before UV radiation) and superabsorbent polymer particles after UV radiation were determined according to the test methods listed above. The results are summarized in Table 1.

[0227] Table 1

[0228]

Material

mean radiation time

(minute)

centrifuge retention capacity

(g / g)

at 0.7kPa(0.1psi)

Saline flow conductivity

(10 -7 cm 3 sg -1 )

[0229] Superabsorption before radiation

polymer particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com