Space aromatic vinegar and brewing technique thereof

A technology of space and balsamic vinegar, applied in the field of space balsamic vinegar and its brewing process, can solve the problems of no breakthrough improvement, poor economic benefits, low nutritional content, etc., achieve good social benefits, improve vinegar production efficiency, and transform raw materials high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

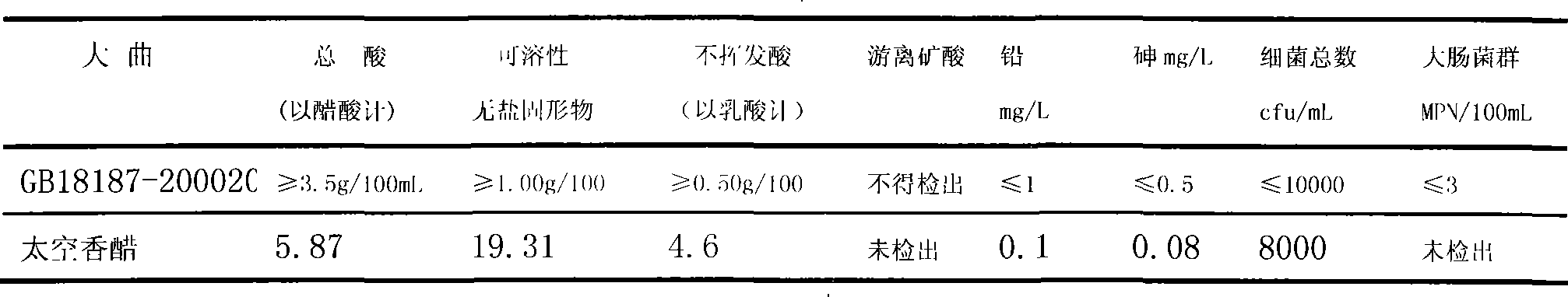

[0018] The raw materials used in space balsamic vinegar are wheat, barley, highland barley, tartary buckwheat, peas, apple juice and wheat bran. 2%, brewed according to the special brewing process of space balsamic vinegar, the finished vinegar is brownish red, concentrated acid and aromatic. Its physical and chemical composition and quality inspection indicators are compared with the national standard values in the following table:

[0019]

[0020] The brewing process of space balsamic vinegar is described as follows in sequence according to the brewing process:

[0021] 1. Preparation The raw materials of space balsamic vinegar are wheat, barley, highland barley, bitter wheat, peas, apple juice and wheat bran (that is, wheat bran), and the ratio of grain to wheat bran is 2:8;

[0022] 2. Make koji by adding other raw materials such as wheat bran, black flour (ground from wheat bran) and barley to the old koji induced by space mutation. The ratio of the three is 2:2:4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com