Agitation type pavement deflection tester

A road surface deflection and tester technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of small impulse force and unrepresentative loading range, and achieve the problem of overcoming small loading force, large loading force range and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

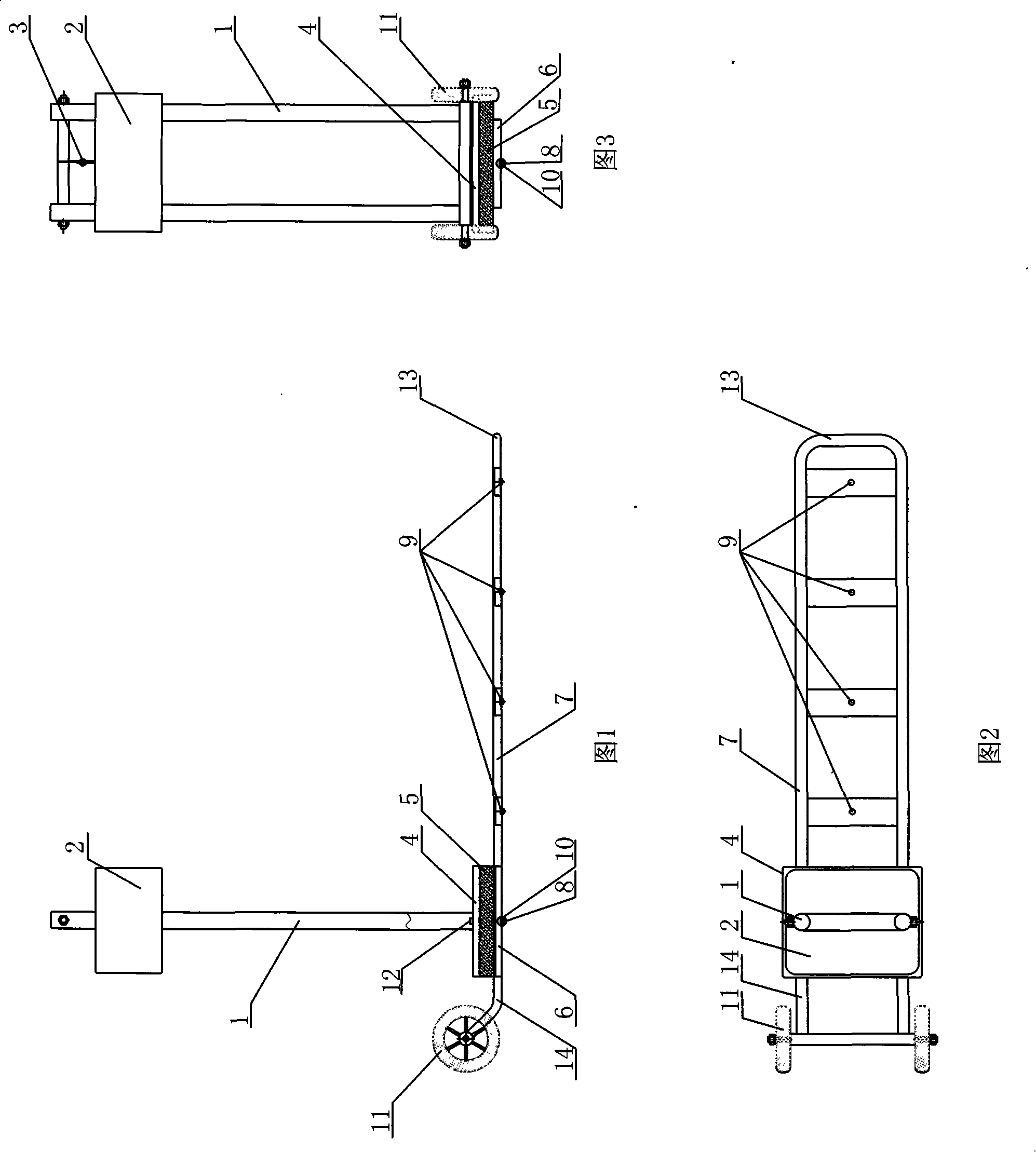

[0016] The excitatory pavement deflection tester consists of a guide rod 1, a weight 2, a release mechanism 3, a load transmission mechanism, a horizontal transmission frame 7, a center displacement sensor 8, an auxiliary displacement sensor 9, a load sensor 10, a walking wheel 11 and an explosive force generator. Mechanism 12 constitutes.

[0017] The load transfer mechanism is composed of a top plate 4 , a buffer block 5 and a bearing plate 6 . The buffer block 5 and the top plate 4 are fixed on the bearing plate 6 from bottom to top. The guide rod 1 is vertically fixed on the top plate 4, and the weight 2 is movably arranged on the top of the guide rod 1 through the release mechanism 3. The bearing plate 6 is fixed on the left end of the horizontal transfer frame 7, and four auxiliary displacement sensors 9 are fixed on the horizontal transfer frame 7 at equal intervals. A push handle 13 is fixed on the right end of the horizontal transfer frame 7 . The traveling wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com