Plastics lumber composite floor and manufacturing method thereof

A technology of composite flooring and plastic wood, which is applied in the field of plastic wood composite flooring and its manufacturing, can solve problems such as cracking and easy deformation, and achieve the effects of cost reduction, stability, thickness, and comfortable pedaling feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

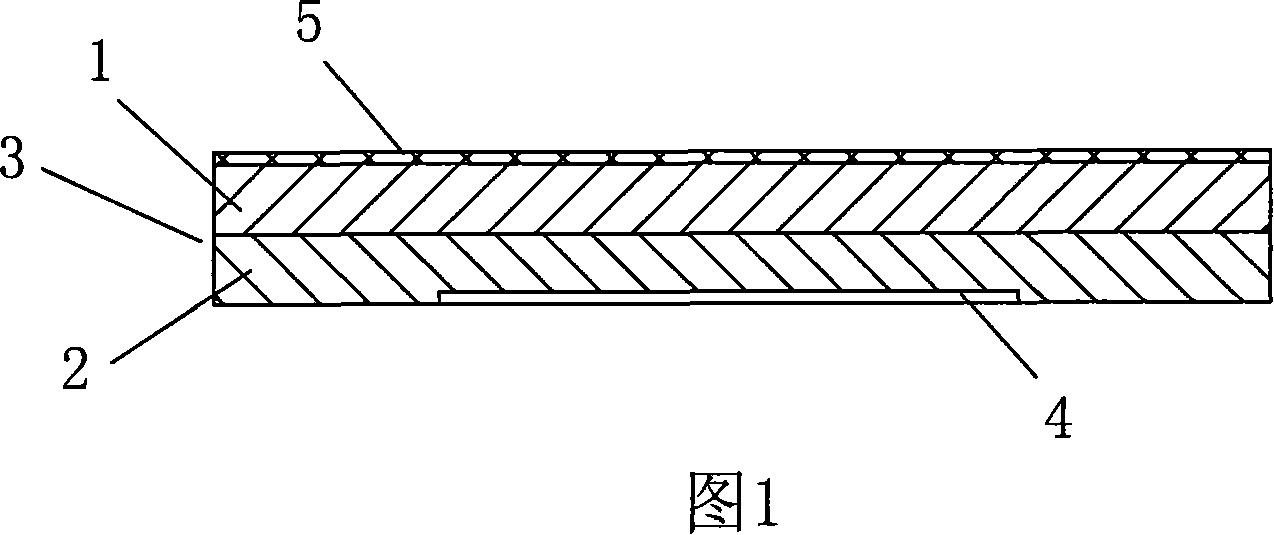

[0024] As shown in FIG. 1 , a plastic wood composite floor includes a wooden layer 1 made of rare solid wood, and an energy-saving and stable plastic layer 2 . The wooden layer 1 and the stable plastic layer 2 are combined to form a floor composite substrate 3 . Wherein, the wooden layer 1 on the floor composite base material 3 is arranged at the upper part, and the plastic layer 2 is arranged at the lower part, and the floor composite base material 1 is also provided with a groove 4 for convenient floor installation.

[0025] The thicknesses of the wooden layer 1 and the stable plastic layer 2 are respectively 9mm, or 12mm, or 15mm or 18mm. Each accounts for half of the thickness of the entire floor composite substrate 3 .

[0026] The wooden layer 1 is also provided with a paint decoration protection outer layer 5 .

[0027] A manufacturing method for realizing the above-mentioned plastic wood composite flooring, comprising the following steps:

[0028] A), according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com