Piezoelectricity resonator

A resonator and piezoelectric technology, applied in the direction of piezoelectric devices/electrostrictive devices, electrical components, impedance networks, etc., can solve cracks, hinder the thinning of piezoelectric resonators with built-in capacitors, and the sealing substrate 103 is prone to cracks And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

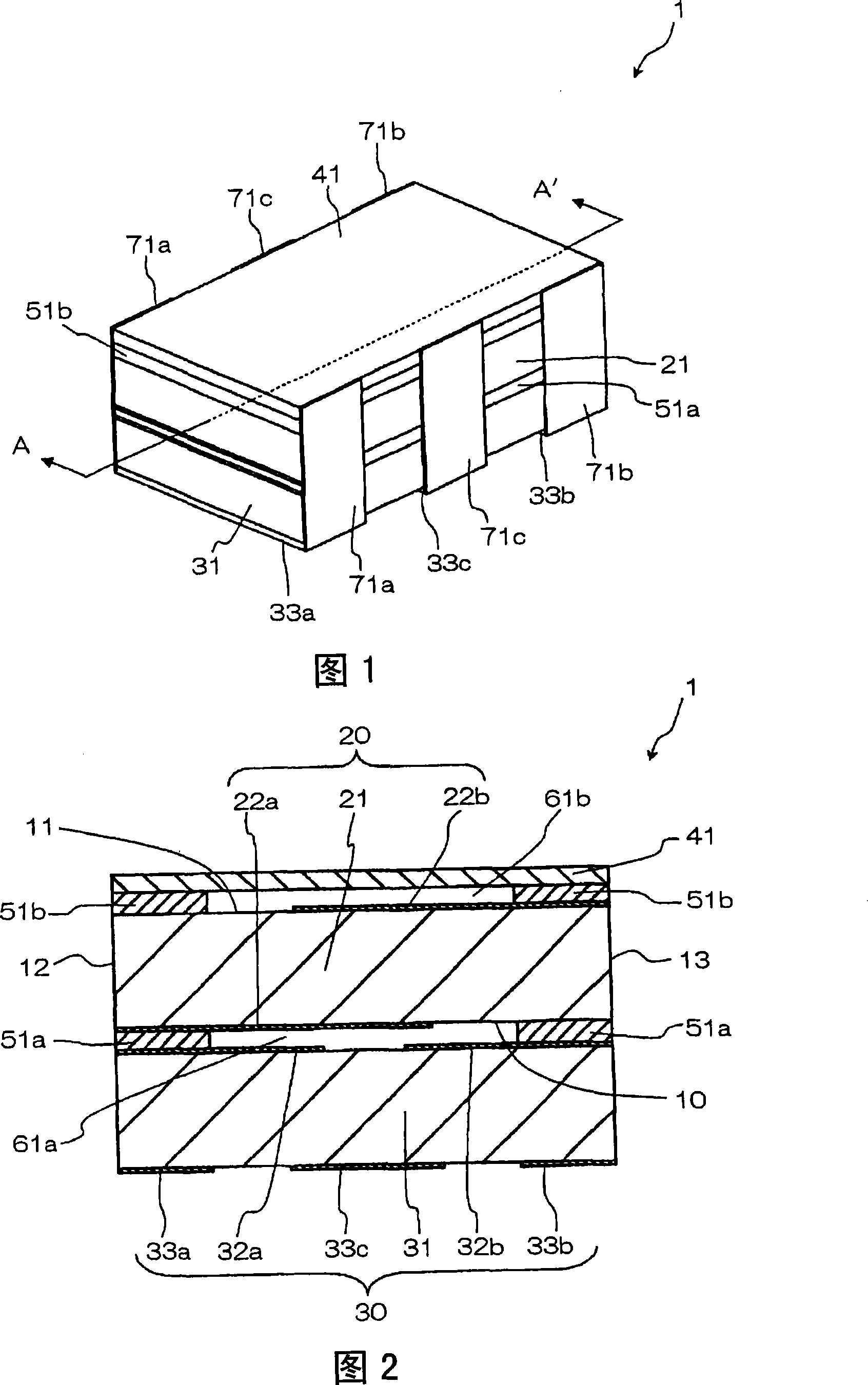

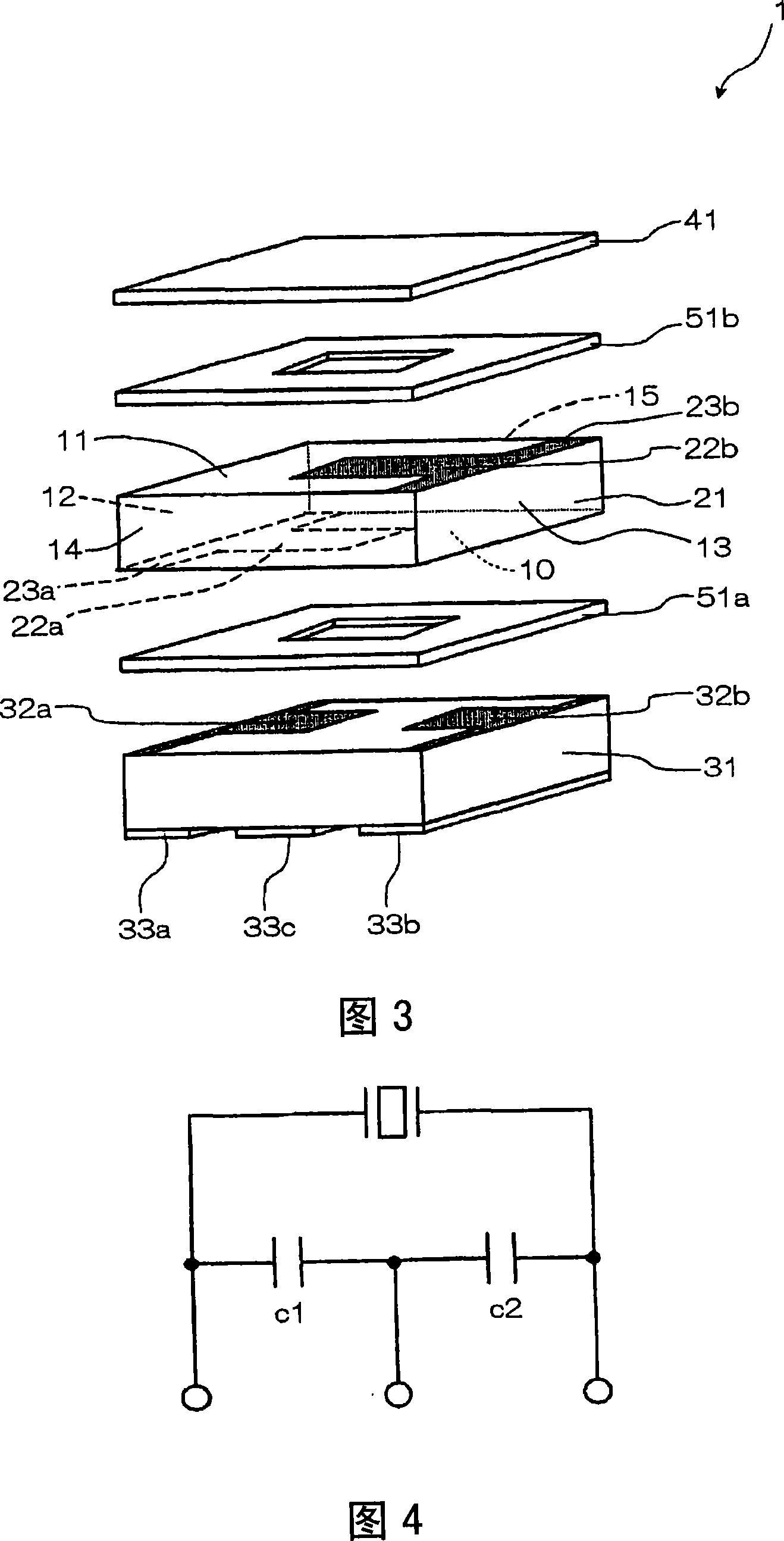

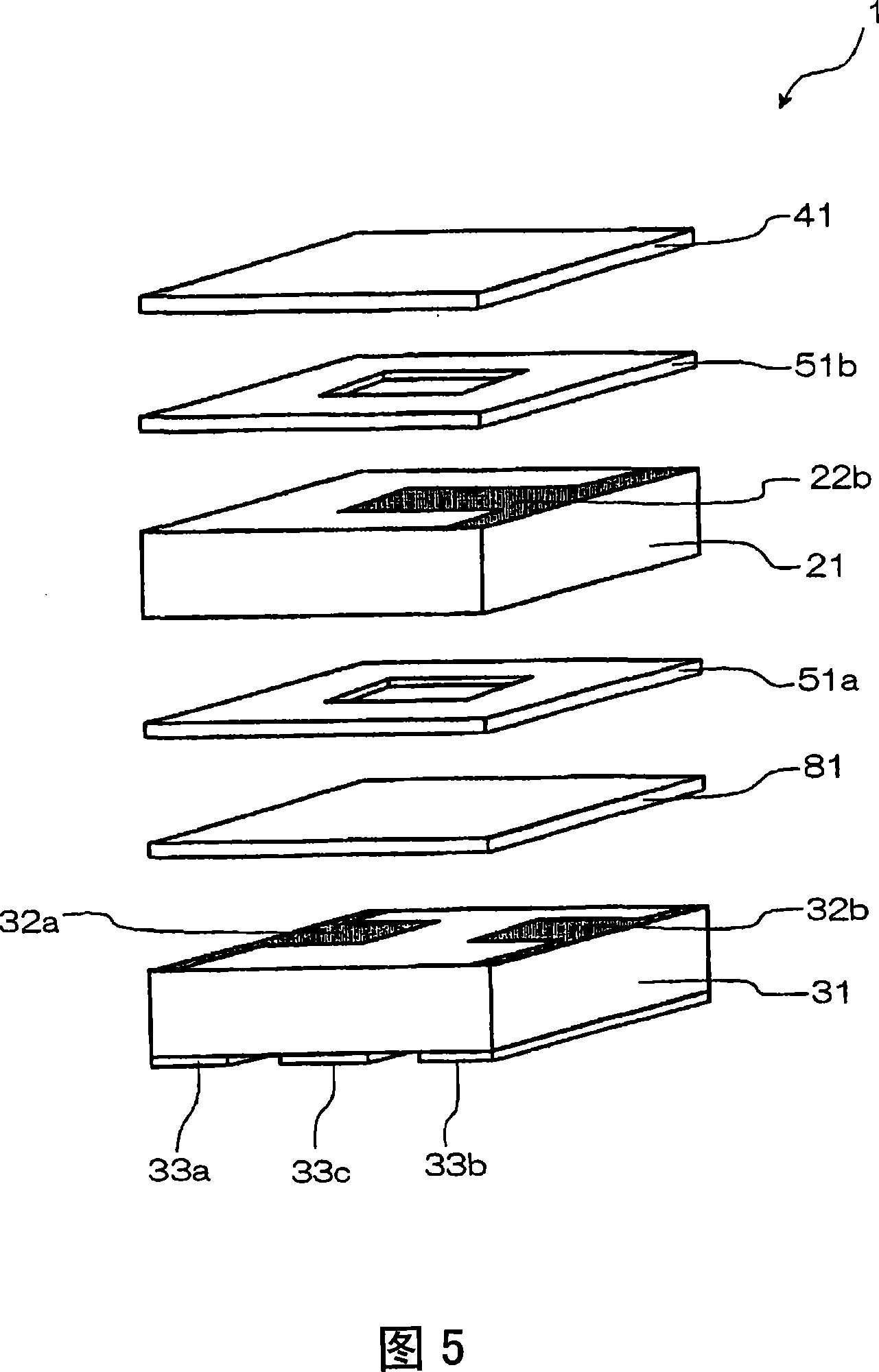

[0032] Hereinafter, the piezoelectric resonator of the present invention will be described in detail based on the drawings.

[0033] Fig. 1 is an external perspective view schematically showing an example of the piezoelectric resonator of the present invention, Fig. 2 is a sectional view taken along line A-A' of Fig. 1 , and Fig. 3 is an exploded perspective view.

[0034] In addition, in this embodiment, a piezoelectric resonator of a type incorporating an electrostatic capacitance will be described.

[0035] The piezoelectric resonator 1 shown in the figure mainly includes: a piezoelectric substrate 21 and two sealing substrates 31 , 41 . More specifically, as shown in FIG. 2 , the first sealing substrate 31 is bonded to the piezoelectric substrate 21 via the first frame body 51 a to form a first vibration space 61 a on the first main surface 10 side of the piezoelectric substrate 21 , and The second sealing substrate 41 is bonded to the piezoelectric substrate 21 via the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap