Sawmill automatic feeding system

A technology of automatic feeding and feeding system, which is applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems of high labor intensity of operators, inability to carry out automatic production, and inability to carry out continuous production, etc., and achieve the labor intensity of workers Reliable and stable lowering, clamping and feeding, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

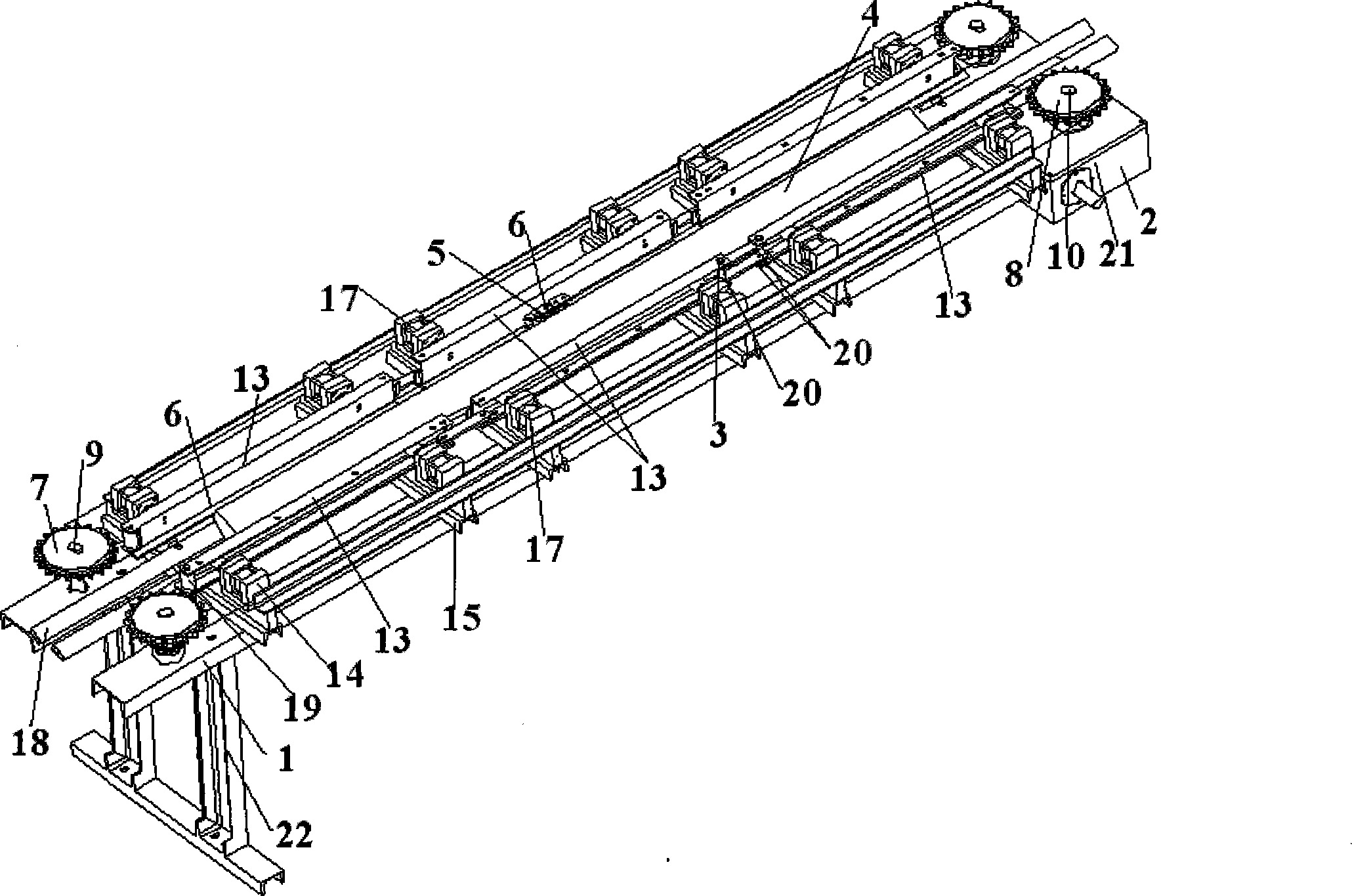

[0038] This embodiment mainly addresses the installation direction of the sprocket transmission mechanism 5 on the support beam 1 of the feeding system.

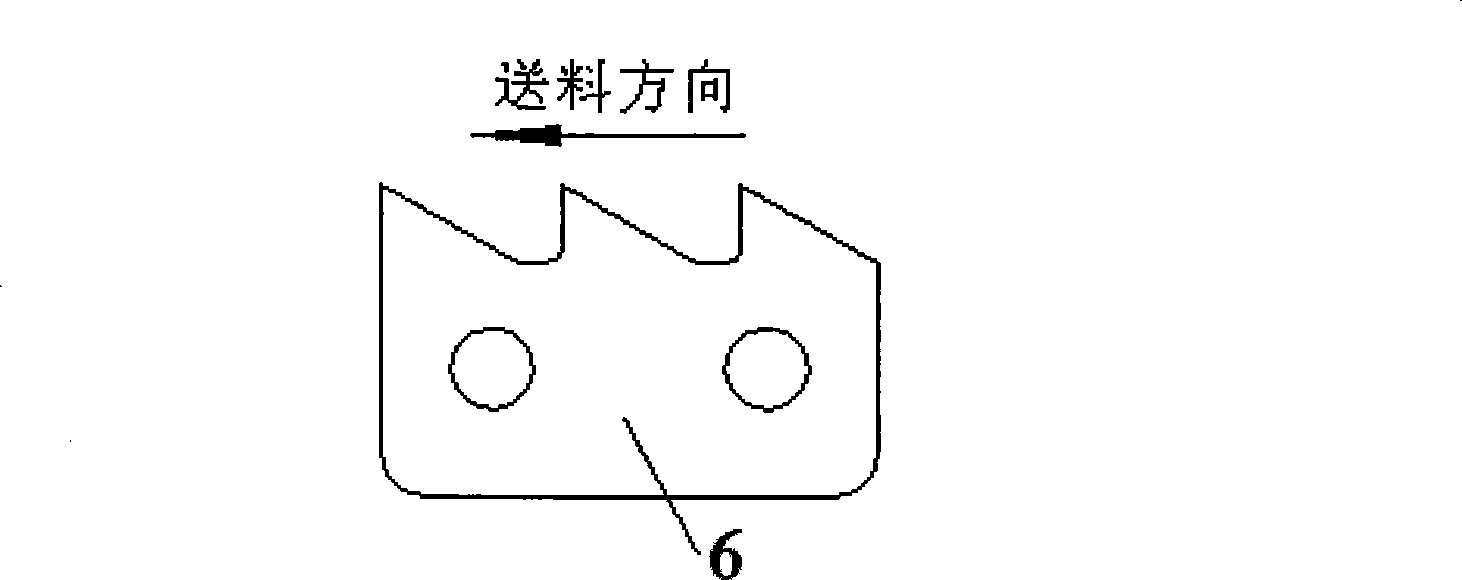

[0039] To enable each sprocket 7 on the sprocket transmission mechanism 5 to be easily installed on the support beam 1 of the feeding system, and to facilitate the operation of the operator and the observation during processing, the sprocket in the sprocket transmission mechanism 5 7 The rotation plane is set horizontally.

[0040] In this way, the sprocket 7 and the chain 6 of the two sprocket transmission mechanisms 5 all operate in a horizontal plane, and the structure is simple, and the operation and observation are very convenient.

Embodiment 2

[0042] An important problem in the present invention is that the two sprocket transmission mechanisms 5 should be fully synchronized, so that the feeding can be carried out reliably and stably. If the chains 6 used for clamping on both sides of the processed wood 4 cannot move synchronously , Will inevitably interfere with each other to damage the machine and even cause accidents.

[0043] This embodiment requires:

[0044] The two sprocket transmission mechanisms 5 have the same structure and are symmetrically distributed according to the center line of the processed wood 4, and are both driven by the feeding drive mechanism 2, so that the two sprocket transmission mechanisms 5 achieve complete synchronization and opposite directions. Rotate.

[0045] Among them, the pitches of the symmetrically distributed sprocket 7 and the chain 6 must be equal; the number of teeth of the symmetrical sprocket 7 must be equal; the direction of rotation must be opposite; the speed of the sprocket ...

Embodiment 3

[0047] The same as the requirements of the second embodiment, in order to achieve complete synchronization of the two sprocket transmission mechanisms 5, in addition to strict requirements on the structure, it is necessary to ensure that the rotation speeds of the two driving sprockets 8 used to drive the chain 6 are exactly the same.

[0048] This embodiment provides the following structure:

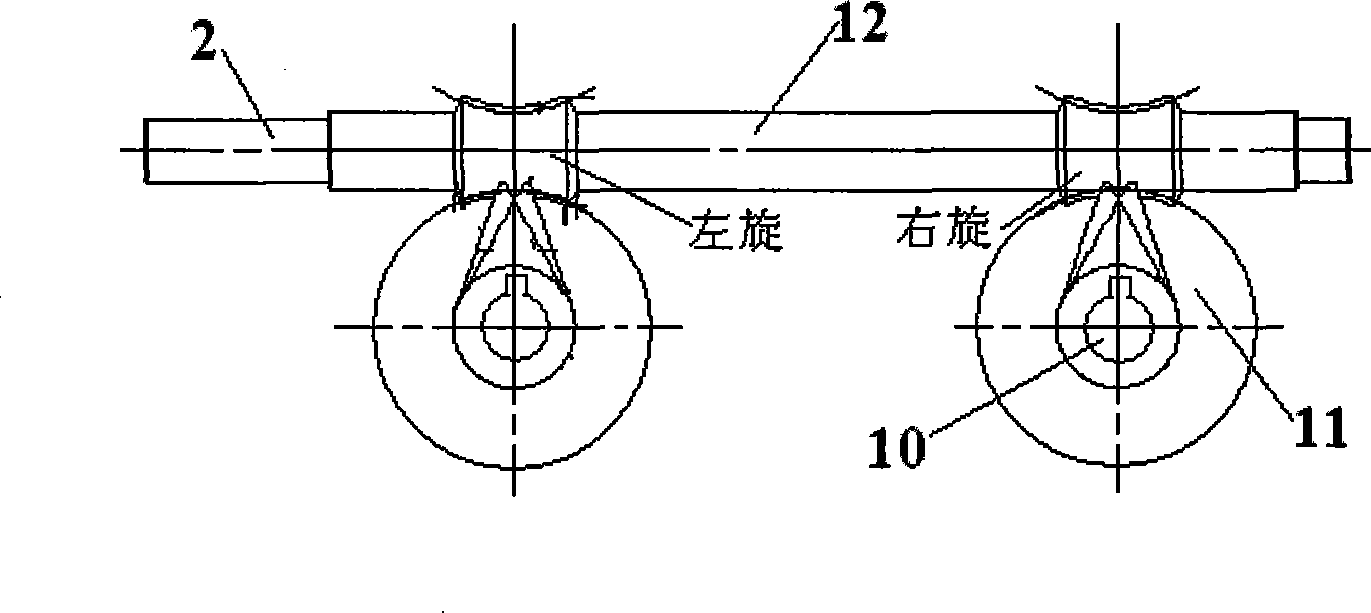

[0049] Such as figure 1 with figure 2 As shown, each of the two sprocket transmission mechanisms 5 is provided with a driving sprocket 8 and a passive sprocket 9. The driving sprocket 8 is at the same end of the two sprocket transmission mechanisms 5, and the driving chain The lower end of the driving sprocket shaft 10 of the wheel 8 is each provided with a worm wheel 11, and both are meshed with the worm 12 in the feeding driving mechanism 2. The worm wheel 11 and the worm 12 are both arranged in the feed drive gearbox 21

[0050] One worm 12 is used to drive the two worm gears 11 to reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com