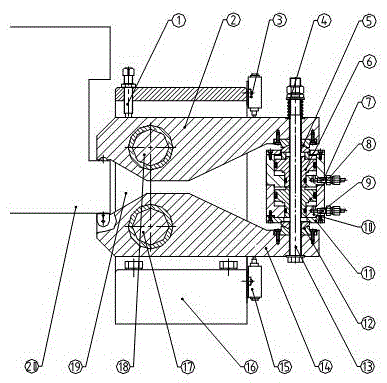

Large vertical lathe turntable clamping device

A clamping device and turntable technology, which is applied to large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of difficult installation and debugging, difficulty in processing annular T-slots, major accidents, etc., and achieve assembly adjustment and maintenance. Convenient, secure and stable clamping, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] exist figure 1 Among them, the present invention is provided with a mechanism body 19, on which the lower rotating shaft 17 and the upper rotating shaft 18 are fixed, the upper scissors body 2 and the lower scissors body 14 can rotate around the upper rotating shaft 18 and the lower rotating shaft 17 respectively, and the machine tool body 16 is screwed with a positioning rod 1. The end of the positioning rod 1 is on the outside of the head of the upper scissors body 2, and the heads of the upper scissors body 2 and the lower scissors body 14 are separated from the rotating part 20 of the turntable by a small distance in the free state due to the action of the spring 4 , and the positioning rod 1 is used to adjust the size of this distance. An oil cylinder body 10 is arranged in the tail of the upper scissors body 2 and the lower scissors body 14. There is an upper piston body 6 inside the oil cylinder body 10, which is in contact with the upper ball washer assembly 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com