Shear resistant transmission belt

A transmission belt and belt body technology, which is applied in the field of transmission belts, can solve the problems of reducing the service life of the transmission belt, accelerating the degree of slippage, and prone to slippage, etc., and achieve the effects of increasing the longitudinal tensile strength, reducing manufacturing costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

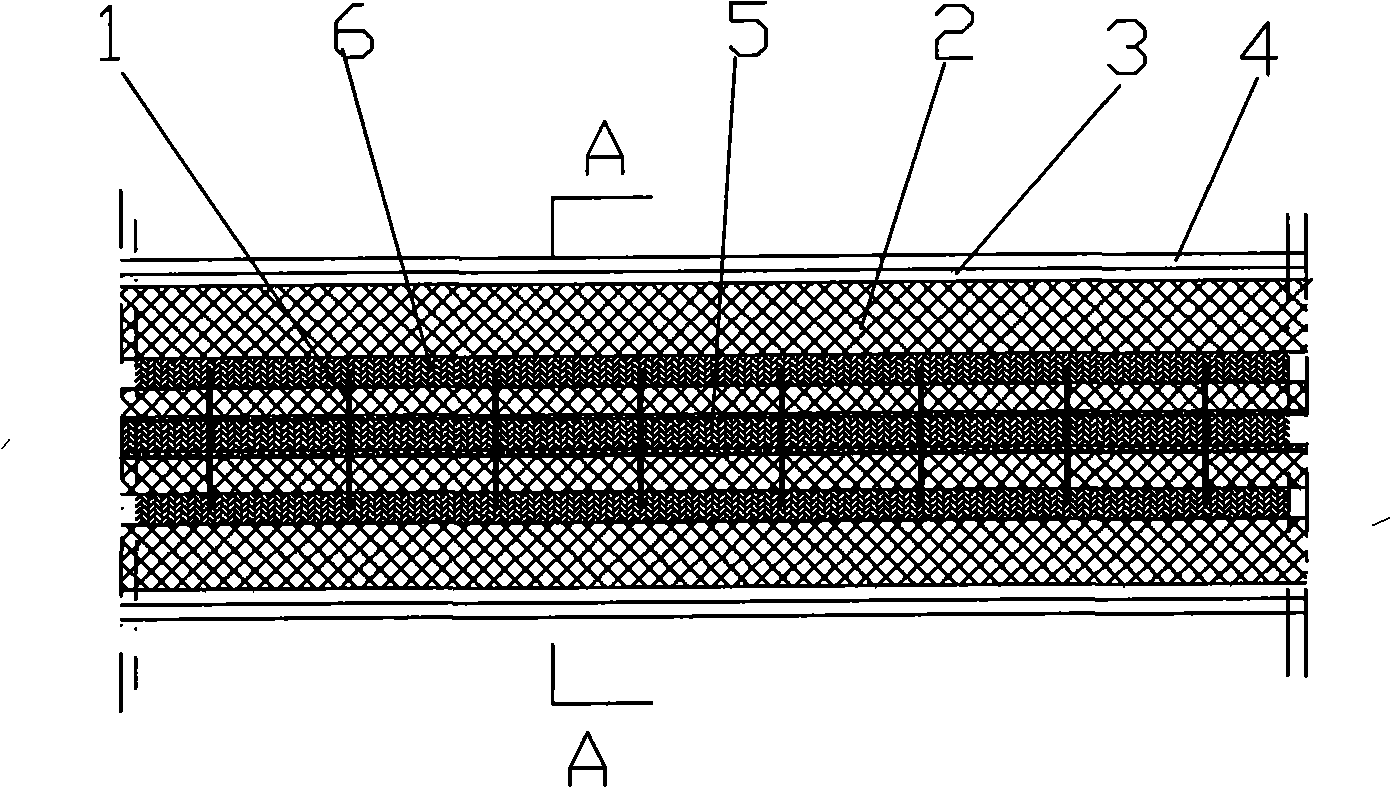

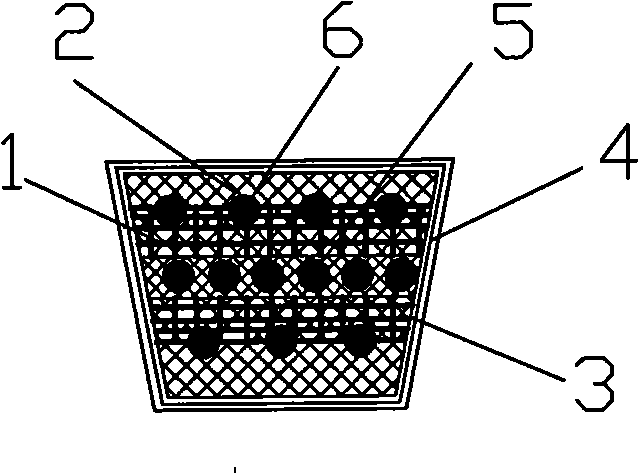

[0016] figure 1 It is the front view of the transmission belt of the present invention, figure 2 for figure 1 Sectional view along A-A direction, as shown in the figure: This transmission belt is a V-shaped belt, and the transmission belt includes a belt body 2 made of a compound based on hydrogenated nitrile rubber. Hydrogenated nitrile rubber has good heat resistance, oil resistance and chemical resistance. The characteristics of corrosion make the transmission belt durable; the belt body 2 is embedded with a reinforcing cord 5 to strengthen the longitudinal strength; the belt body 2 is embedded with a shear key 1 horizontally, and the shear key 1 is fixedly connected with the reinforcing cord 5, And vulcanized with the material of the belt body 2 as a whole, the shear key 1 is a mesh structure wound by metal wire and conformed to the cross section of the belt body; the upper and lower parts of the shear key 1 are respectively longitudinally provided with reinforcement lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com