Gas-liquid separator for heat pump scavenging oil using siphon mode

A gas-liquid separator, heat pump technology, used in heat pumps, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problem of lubricating oil entering, increase service life, prevent liquid shock, improve reliability and refrigeration heating the effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

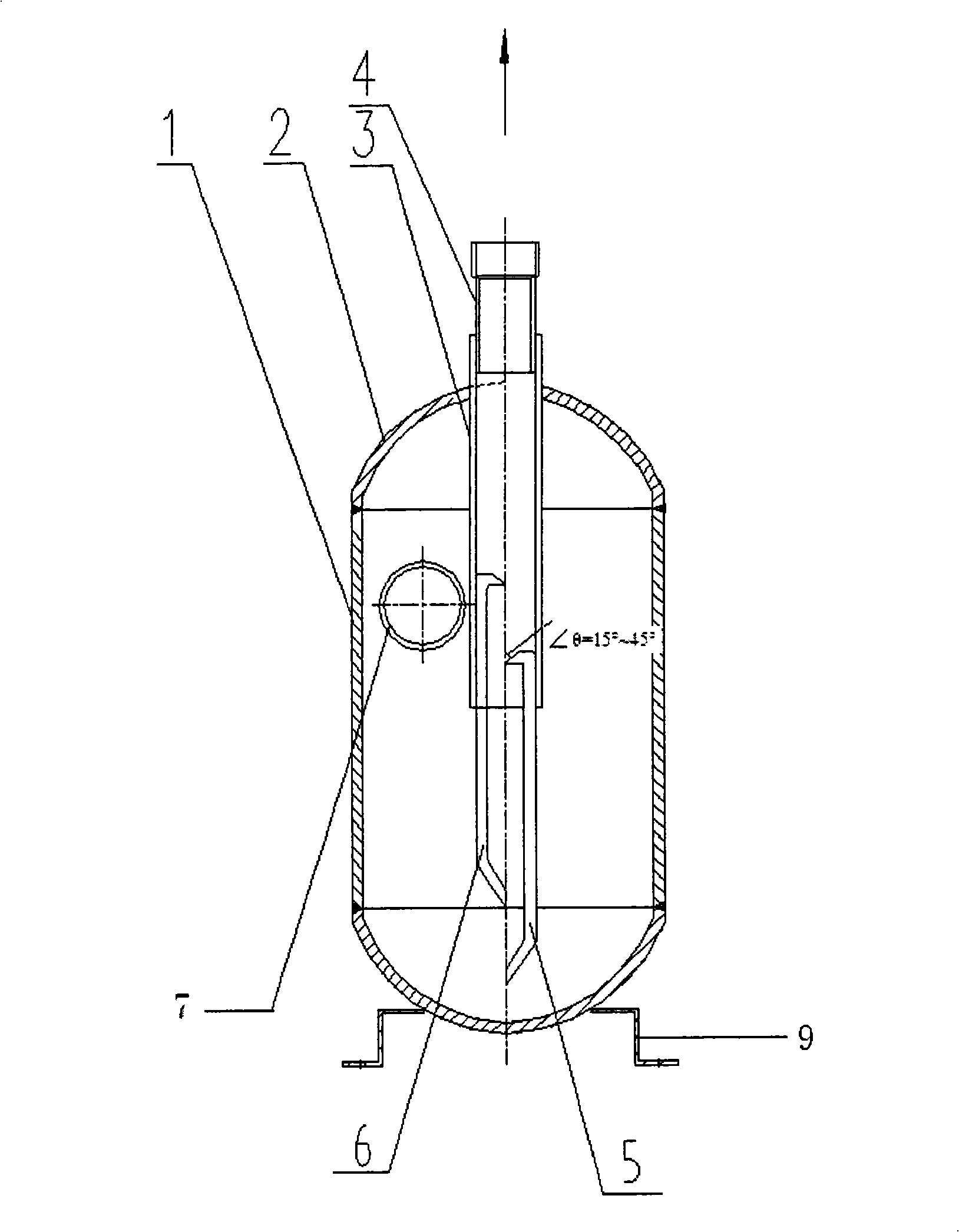

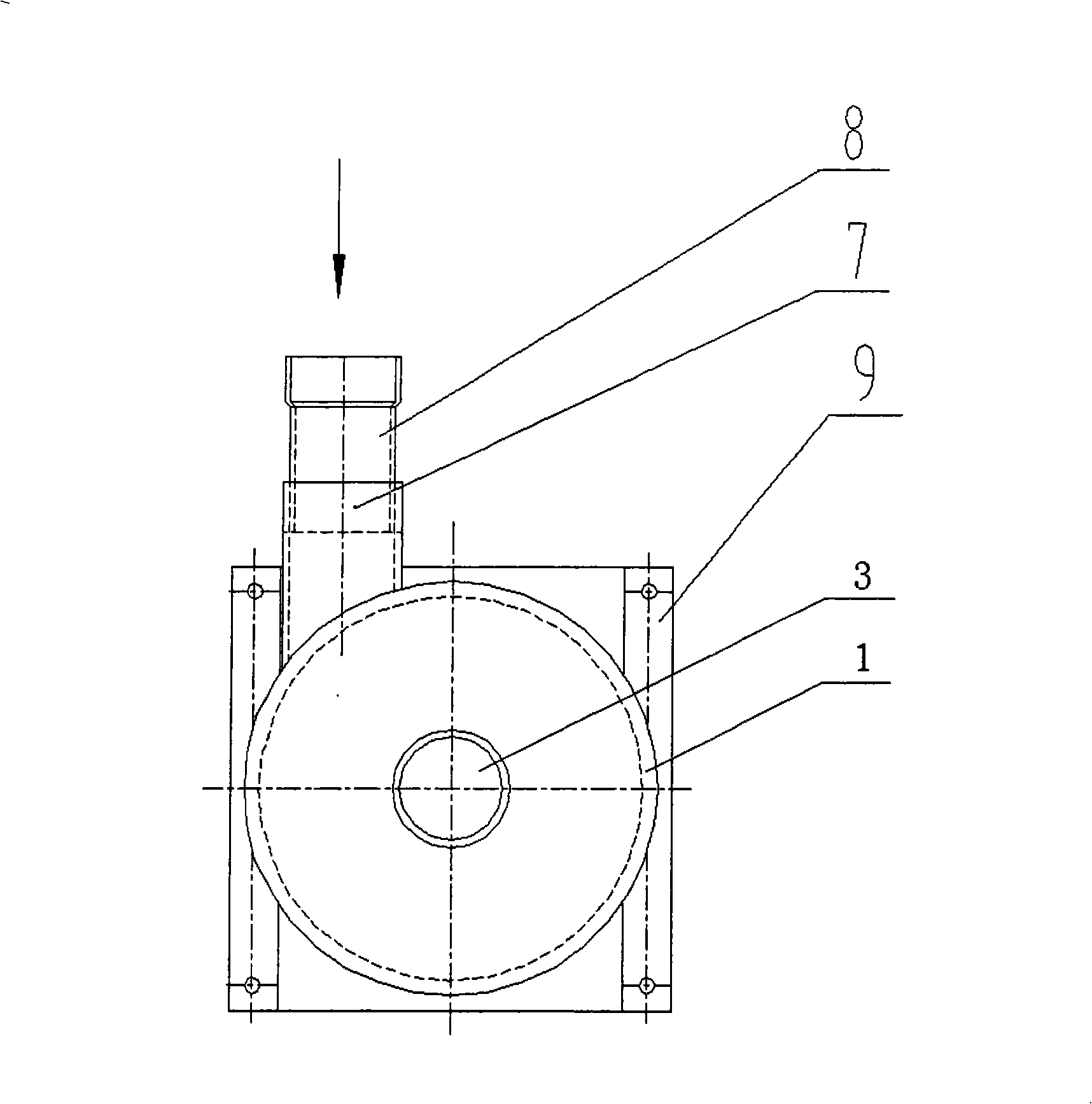

[0014] refer to figure 1 , figure 2 As shown, the cylinder body 1 made of seamless steel pipe in the present invention has a head 2 on the upper part, and a gas return sleeve 3 is installed inside the center of the cylinder body 1, and a gaseous refrigerant gas return pipe in a vertical direction is connected to the upper part of the gas return sleeve 3 4. The tangential direction of the middle part of the cylinder body 1 is welded with an air intake sleeve 7, the air intake sleeve 7 is connected to the intake pipe 8, the bottom of the cylinder body 1 is welded with a base 9, and the inner wall of the return air sleeve 3 is welded with a low oil return pipe 5 and a high position The oil return pipe 6, the low oil return pipe 5 and the high oil return pipe 6 pipe ends all stretch out from the lower opening of the inner wall, and the low oil return pipe 5 is lower than the high oil return pipe 6 about 1 / 5~1 / 4 of the pipe length. The position of the air intake pipe 8 is higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com