Device for separating a gas-liquid mixture

A gas-liquid mixture and separation device technology, applied in separation methods, dispersed particle separation, chemical/physical processes, etc., can solve problems such as poor separation efficiency and achieve the effect of improving fluid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

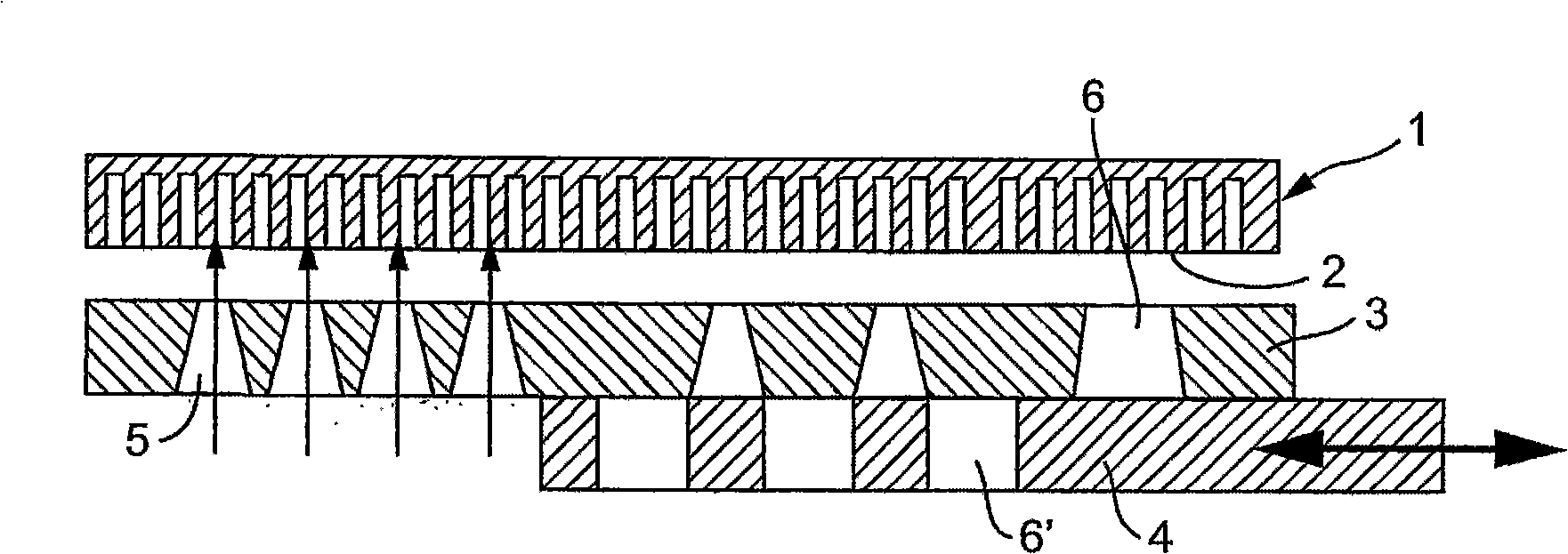

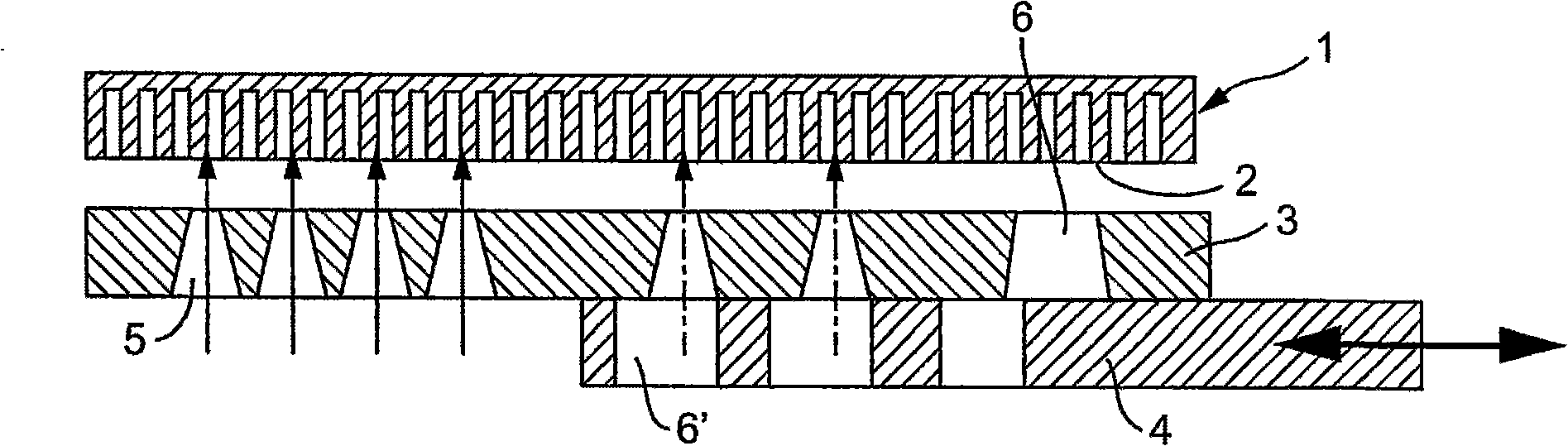

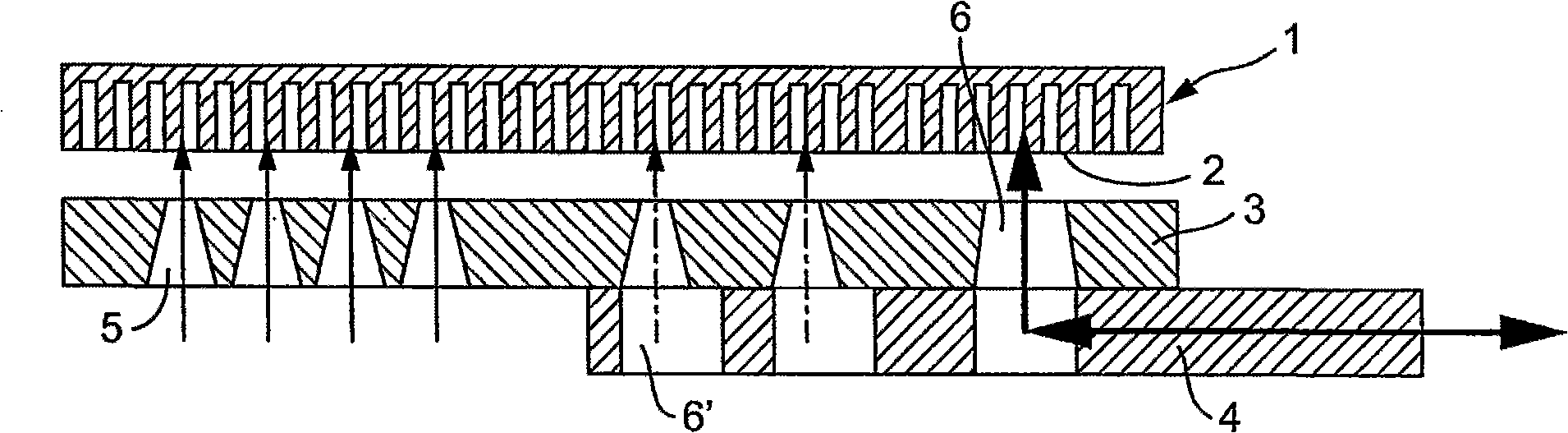

[0023] figure 1

[0024] In the embodiment shown in FIG. 1, a separating device comprises an impact element 1 of plate-like construction. The percussion element has a percussion surface which can be fed through the grid-like arrangement of partitions 2 .

[0025] Close to the percussion element 1 is a device consisting of a connecting rod 3 and a slide valve 4 associated therewith. The connecting rod 3 comprises first and second acceleration openings 5 and 6 . Opening 6 ' on the spool valve 4 cooperates with the second acceleration opening 6. With the movement of the spool valve 4, the acceleration opening 6 on the connecting rod 3 is closed or opened. In the open state of the second accelerating opening 6, the opening 6' on the slide valve makes the flow through cross section of the second accelerating opening 6 completely or partially unblocked. The openings 6' are arranged on the spool valve 4 in such a way that when the position of the spool changes, a part of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com