Method for producing plastic film

A film manufacturing method and plastic technology, applied in the field of manufacturing plastic films, can solve problems such as low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

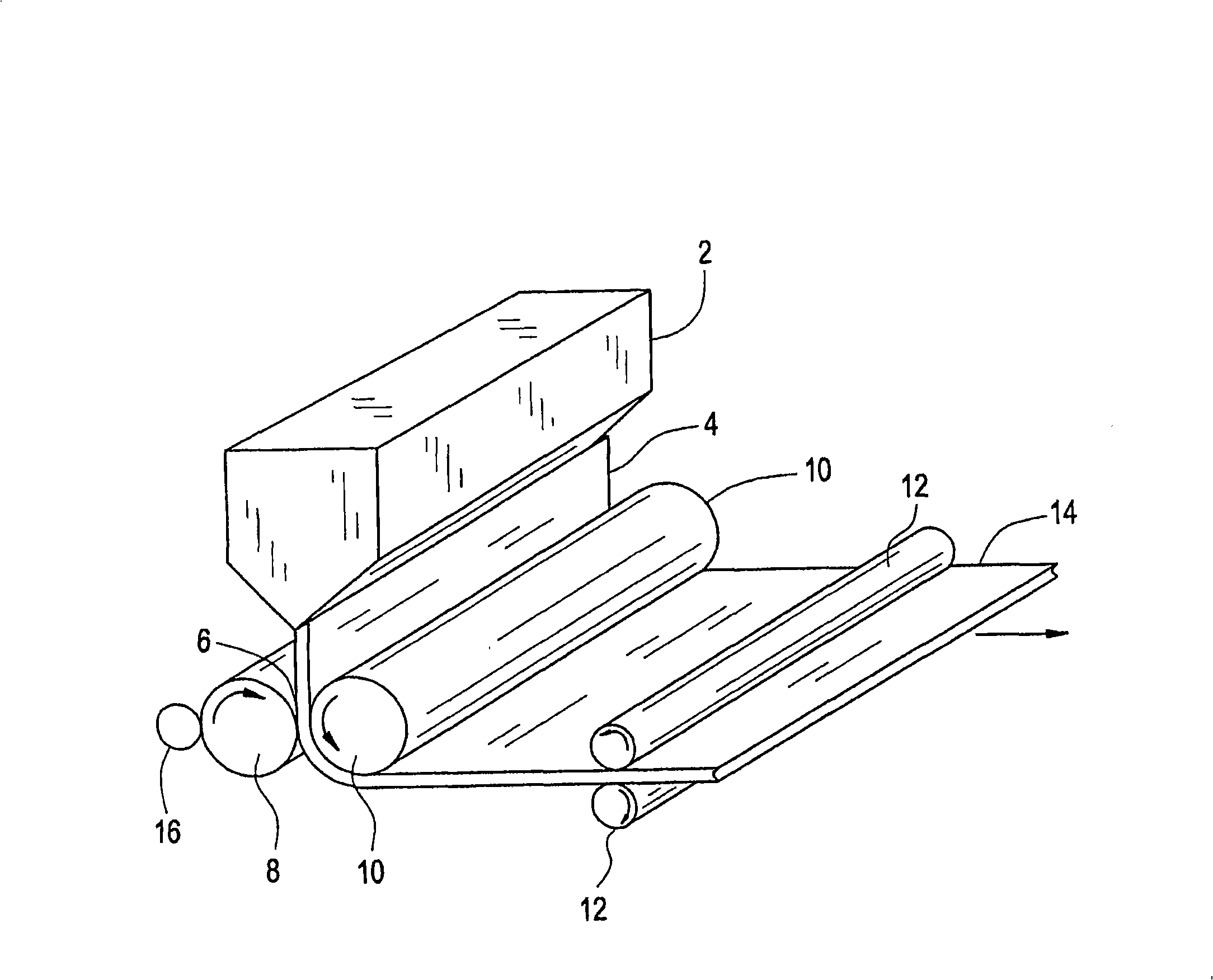

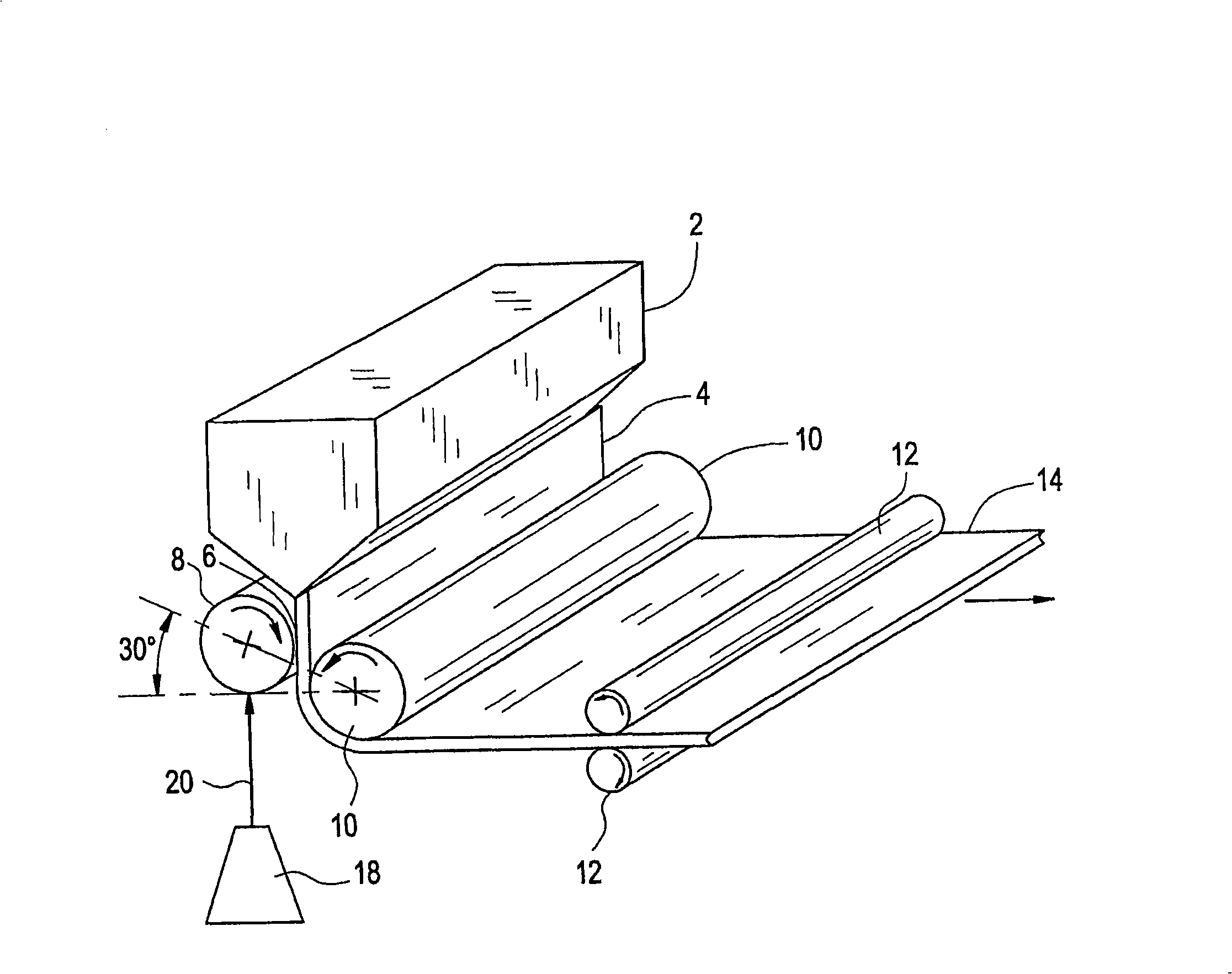

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Polycarbonate (PC) resin was extruded at 270°C into a base film with a thickness of about 175 microns. The film was passed between a polished chrome calender roll maintained at 127°C and a steel calender roll coated with a 0.5 inch (approximately 1.3 centimeter (cm)) thick, 70 durometer (Shore A) silicone rubber extrude. Both rolls were internally cooled with water at a temperature of 43°C. A base film with an optical retardation gradient of 7.2 nm / in retardation and a 40% haze was obtained at a line velocity of 19 feet per minute (ftlmin) (about 5.8 meters per minute (m / min)). It should be noted that optical retardation was measured every 0.25 inches (0.64 cm) along the entire length of the film in establishing the stress profile used to obtain this optical retardation gradient.

Embodiment 2

[0040] Example 2: A PC film was prepared at a line speed of 66 ft / min (20 m / min). The haze of the PC film varied between 36% and 90% (measured according to ASTM D1003 standard) when cooled using an air knife at different cooling locations on the surface of the rubber roll at different air rates. The haze value of the PC film showed a good correlation with the surface temperature of the elastic rubber roller. From a manufacturing point of view, the air knife is mounted under the rubber for easy installation. The velocity of the gas flow was kept below 8 meters per second (m / s) to reduce the risk of disturbing the polymer melt.

Embodiment 3

[0041] Example 3: A PC film was prepared at a line speed of 49 ft / min (15 m / min). After applying the cooling techniques shown in Table 1, the haze of this PC film varied from 15% to 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Haze value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com