Method for preparing solid acid catalyst

A technology of solid acid catalyst and molecular sieve, which is applied in the preparation of organic compounds, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of high production cost and large amount of sewage, so as to reduce production cost, reduce the amount of sewage, and select good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

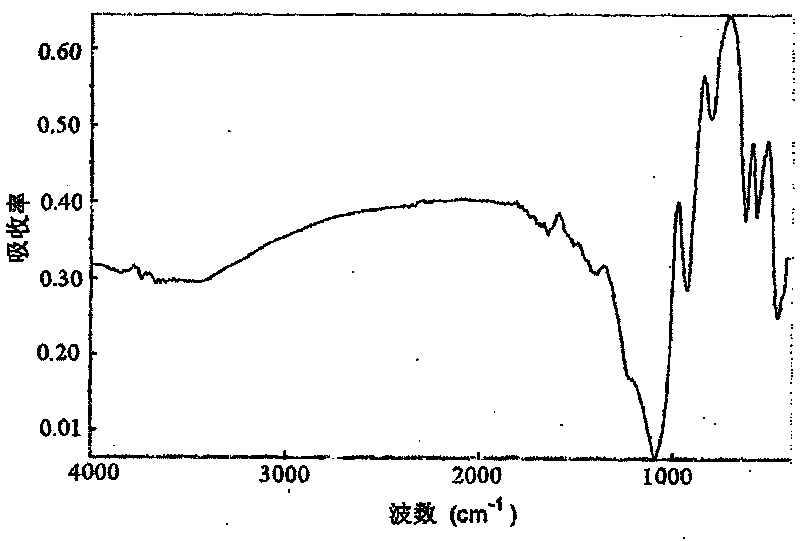

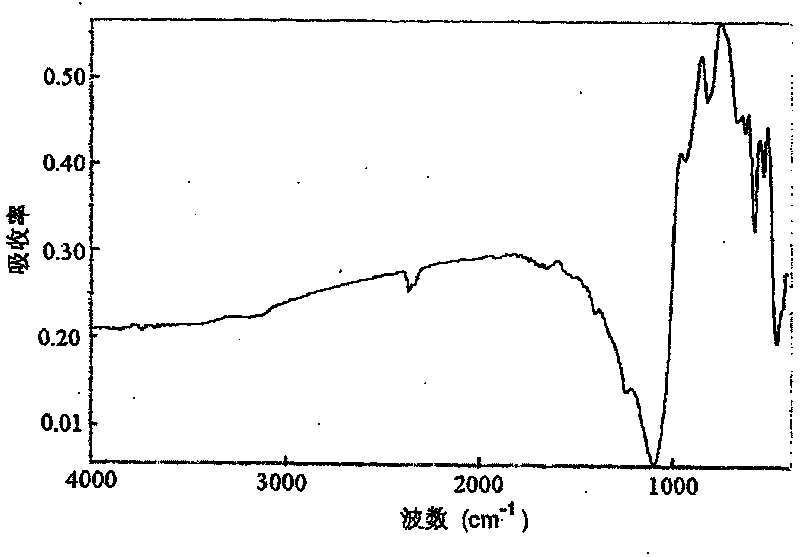

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment 1: The steps of the preparation method of the solid acid catalyst in this embodiment are as follows: 1. Ammonization of the molecular sieve: dry the molecular sieve at 120-200° C. for 1-5 hours, and then put the dried molecular sieve into a concentration of 0.5- In 2mol / L ammonium chloride solution, react at 80-100°C for 1.5-3h, then wash with water at 60-100°C until there is no chloride ion, and then dry at 100-150°C for 12-24h to obtain Ammonium-type molecular sieve; 2. Roasting: Roast ammonium-type molecular sieve at 400-600°C for 2-4 hours to obtain hydrogen-type molecular sieve; Aluminum, wherein the degree of dealumination reaches 2-80% (weight), to obtain dealuminated molecular sieve; 4. Impregnation: the dealuminated molecular sieve is impregnated in the impregnation solution for 0.1-4h by equal volume impregnation method or vacuum impregnation method; 5. Hydrothermal treatment The method comprises: carrying out hydrothermal treatment on the ...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the molecular sieve in step 1 is X-type molecular sieve, Y-type molecular sieve, ZSM-12 molecular sieve or β-type molecular sieve. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is different from Embodiment 1 in that the calcination temperature in step 2 is 550°C. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com