Bolting machine

A technology of screwing and cylinders, applied in power tools, portable mobile devices, manufacturing tools, etc., can solve problems such as reducing exhaust efficiency, and achieve the effect of large exhaust flow and high exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

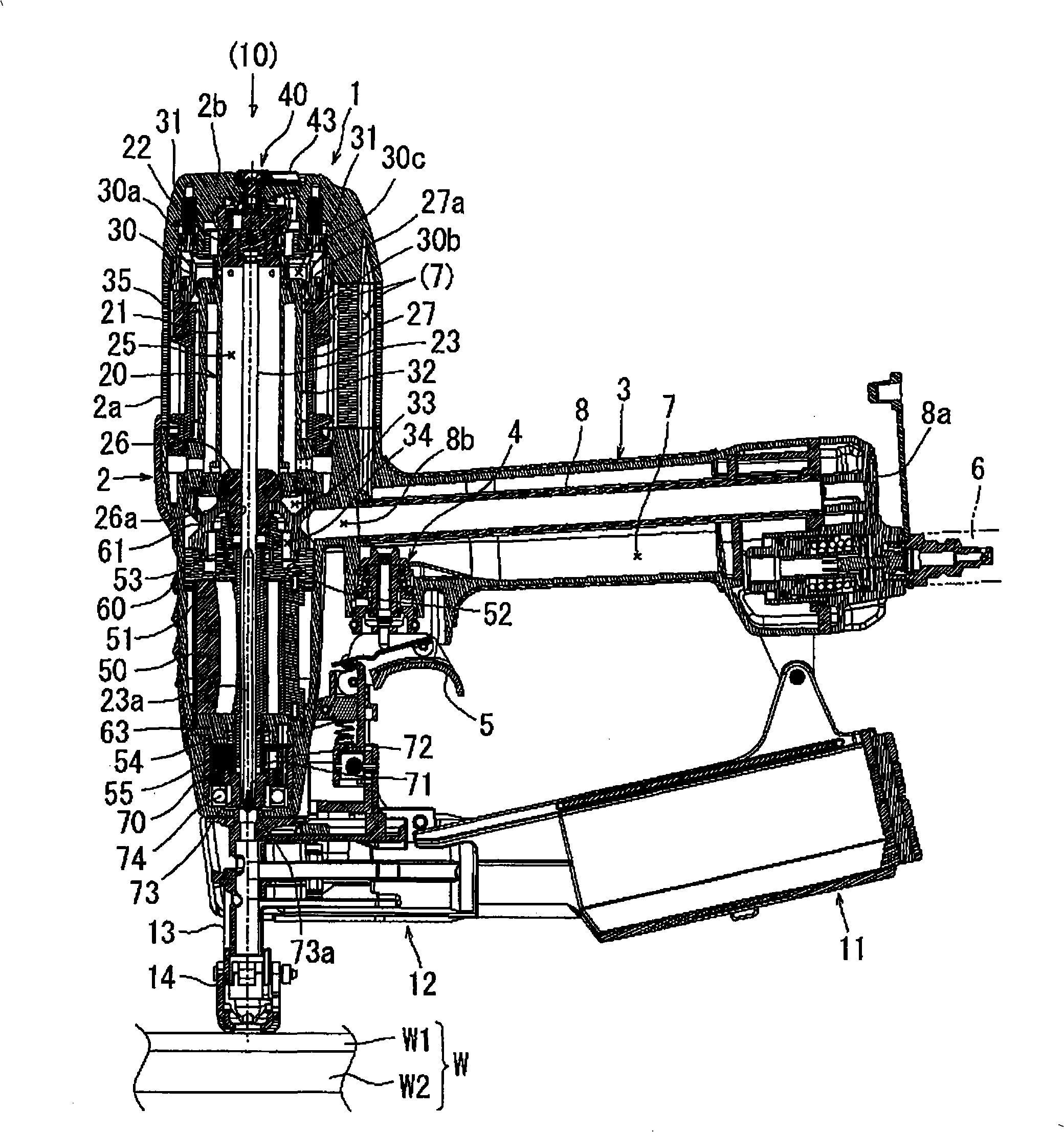

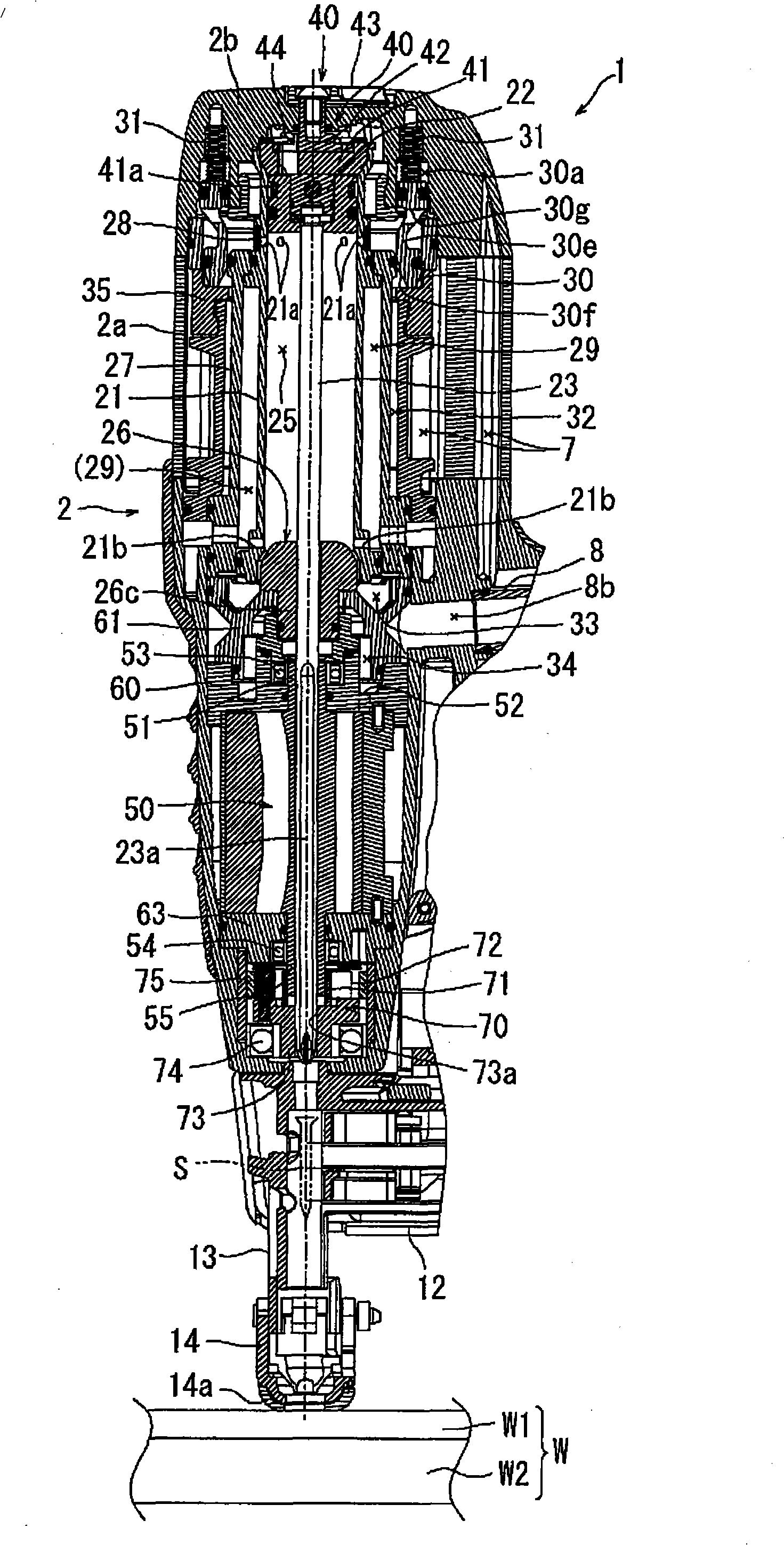

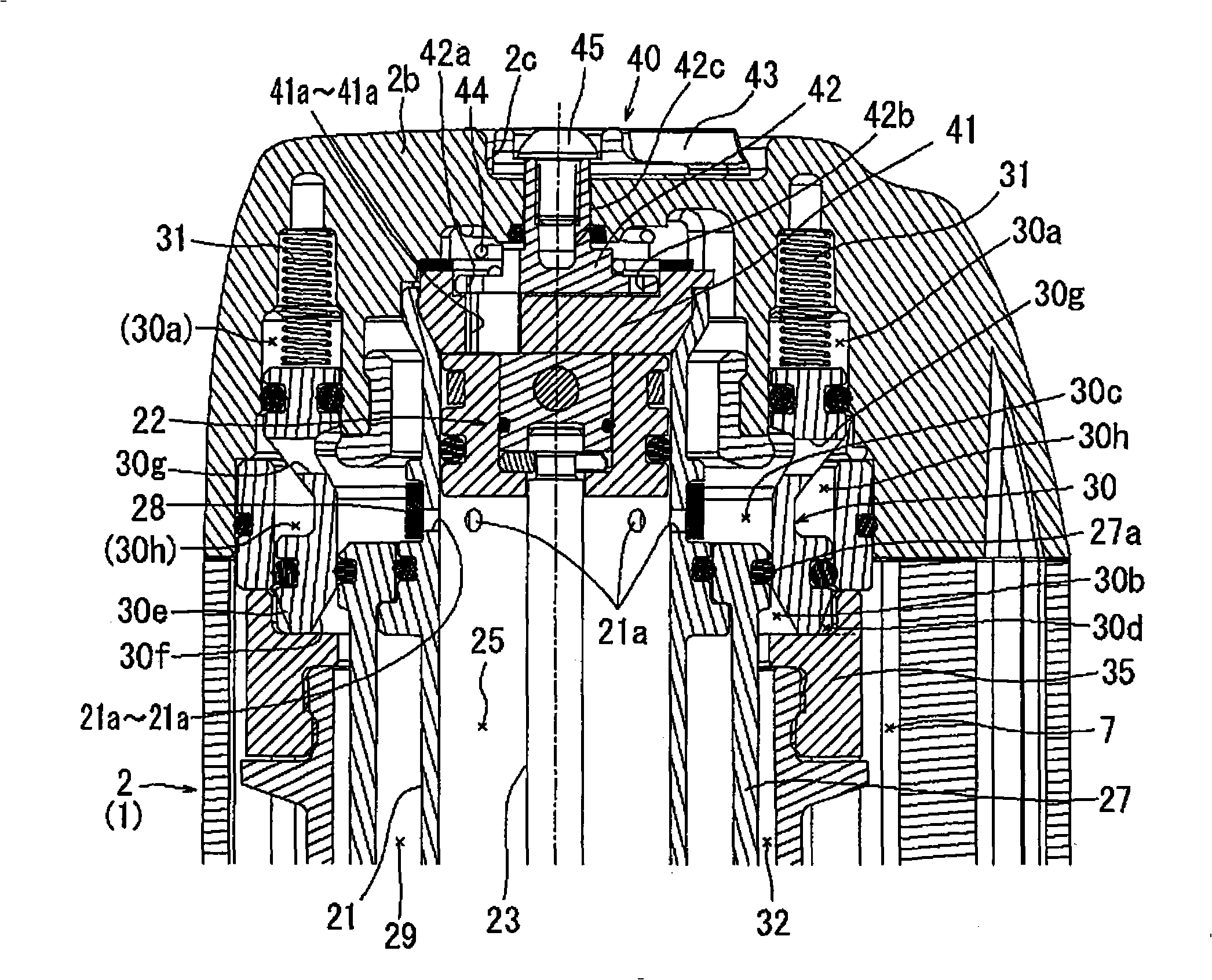

[0037] Below, based on Figure 1 to Figure 16 Embodiments of the present invention will be described. figure 1 and figure 2 The non-operating state (initial state) of the screw driver 1 according to this embodiment is shown. This screwdriver 1 includes a main body 2 having a substantially cylindrical shape, and a handle 3 protruding laterally from the substantially center of the main body 2 in the longitudinal direction. Near the base of the handle portion 3, a trigger valve 4 is disposed. The trigger valve 4 is opened and closed by a trigger 5 that is pulled by a user with a fingertip. Since the trigger valve 4 itself is the same as a conventionally known valve and does not need to be particularly changed in this embodiment, detailed description of its configuration and operation will be omitted.

[0038] When the user pulls the trigger 5, that is, from the front end of the main body part 2 ( figure 1 Middle and lower end) Drive a screw S into the screw driving material...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap