Four side pressurized sealed high pressure resistant sealed ring possessing framework

A sealed, high-pressure-resistant technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problem that the annular sealing ring cannot withstand high pressure on all sides, and achieve the effect of simple structure, increased bonding force, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

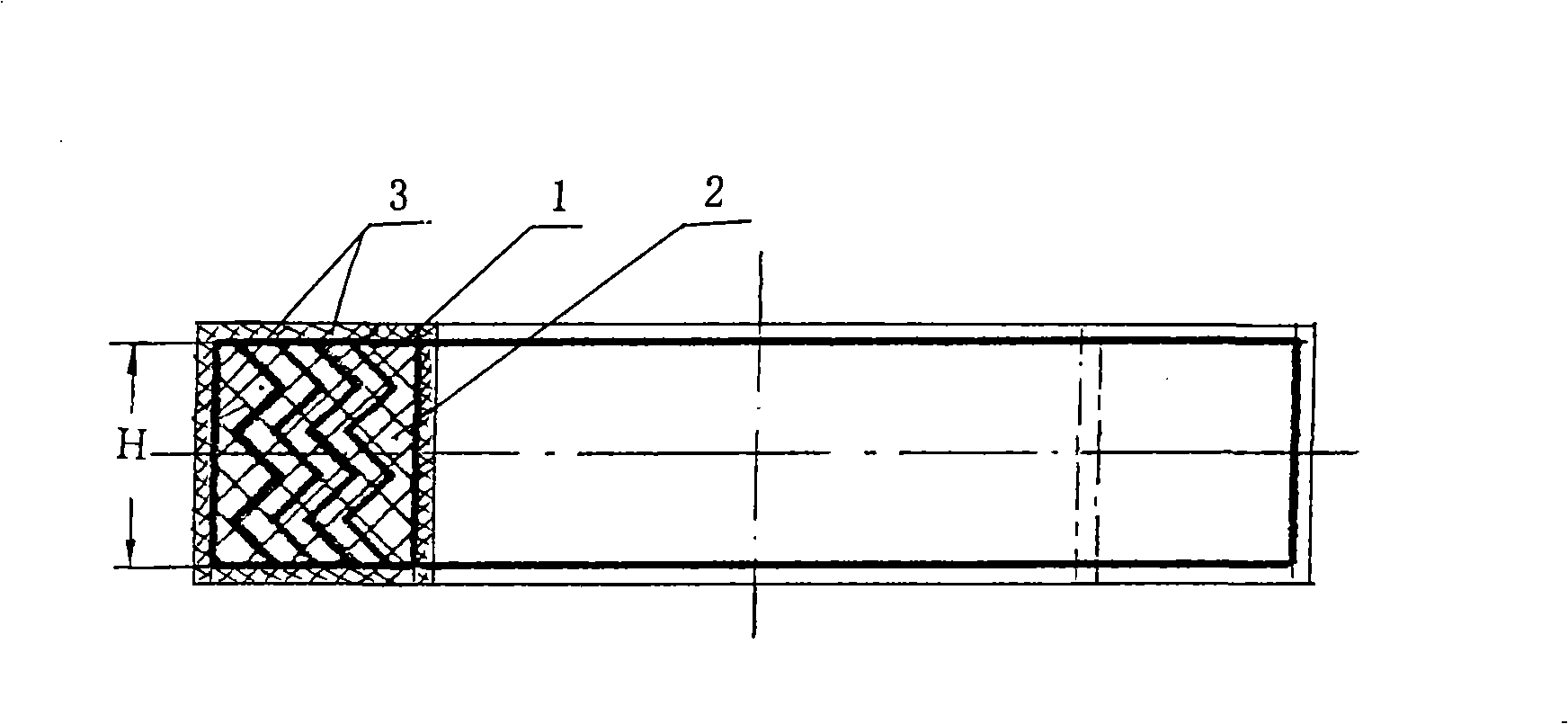

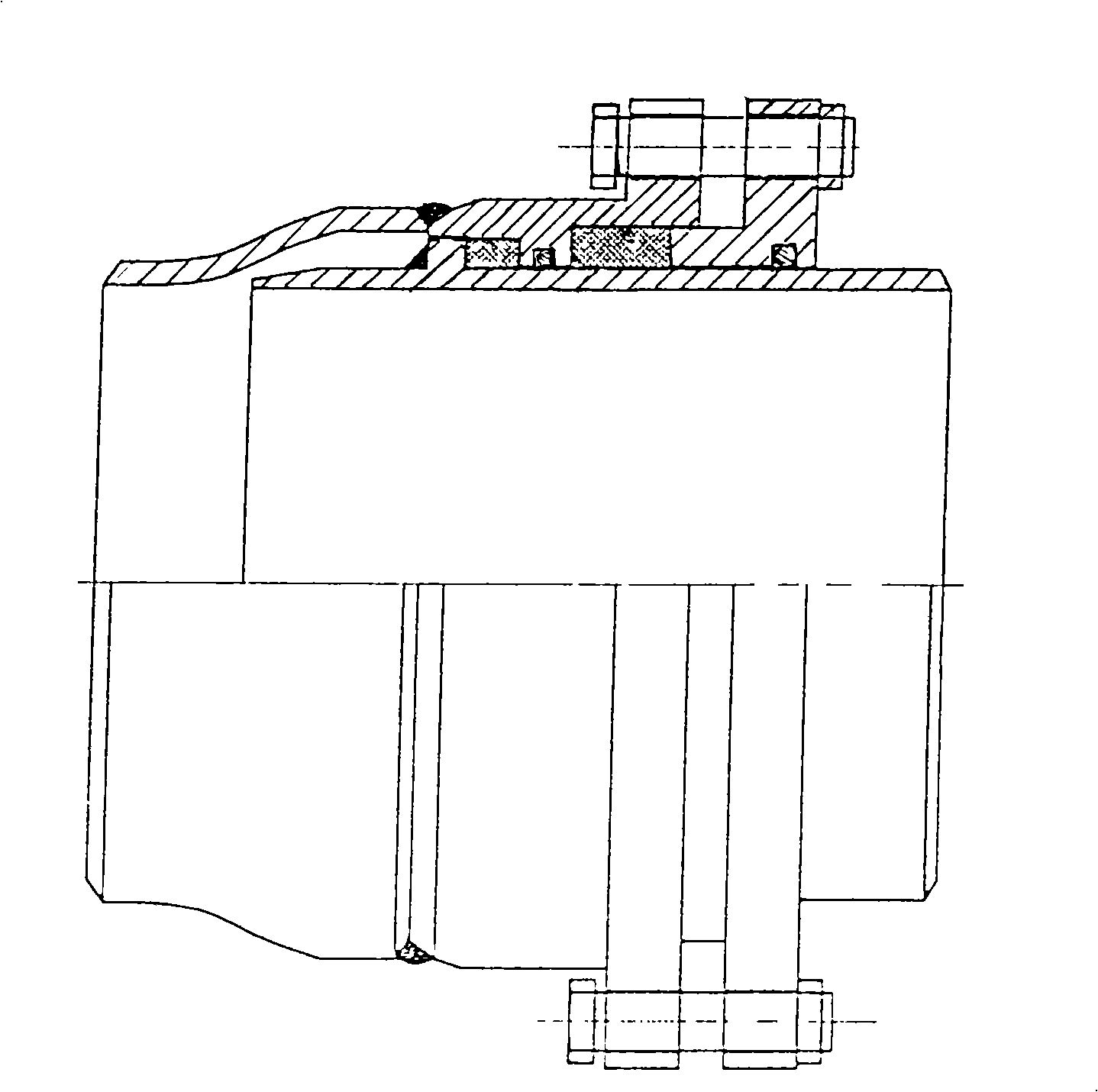

[0021] A four-sided pressure-sealed high-pressure-resistant sealing ring with a skeleton, which is formed by laminating and winding a long skeleton 1 with a width of not less than 10mm and a long flexible sealing material 2, and on both ends of the wound annular ring And the outer and inner circular surfaces are provided with cladding layer 3, its compressive strength is between 200MPa ~ 480MPa, such as figure 1 shown. During specific implementation, the skeleton 1 can be one or a combination of flat plates, corrugated plates, toothed plates or arc-shaped plates, wherein figure 1 The corrugated plate shape shown has the best compressive strength, and the skeleton 1 of the corresponding shape can be selected according to the maximum pressure surface borne by the sealing ring in the actual implementation. When the main direction of force is the end face,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Height h | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com