Vacuum container, pressure-resisting containing and sealing method thereof

A vacuum vessel and pressure vessel technology, applied in the direction of pressure vessel/vacuum vessel, pressure vessel used in chemical process, semiconductor/solid device manufacturing, etc., can solve problems such as manufacturing difficulties and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

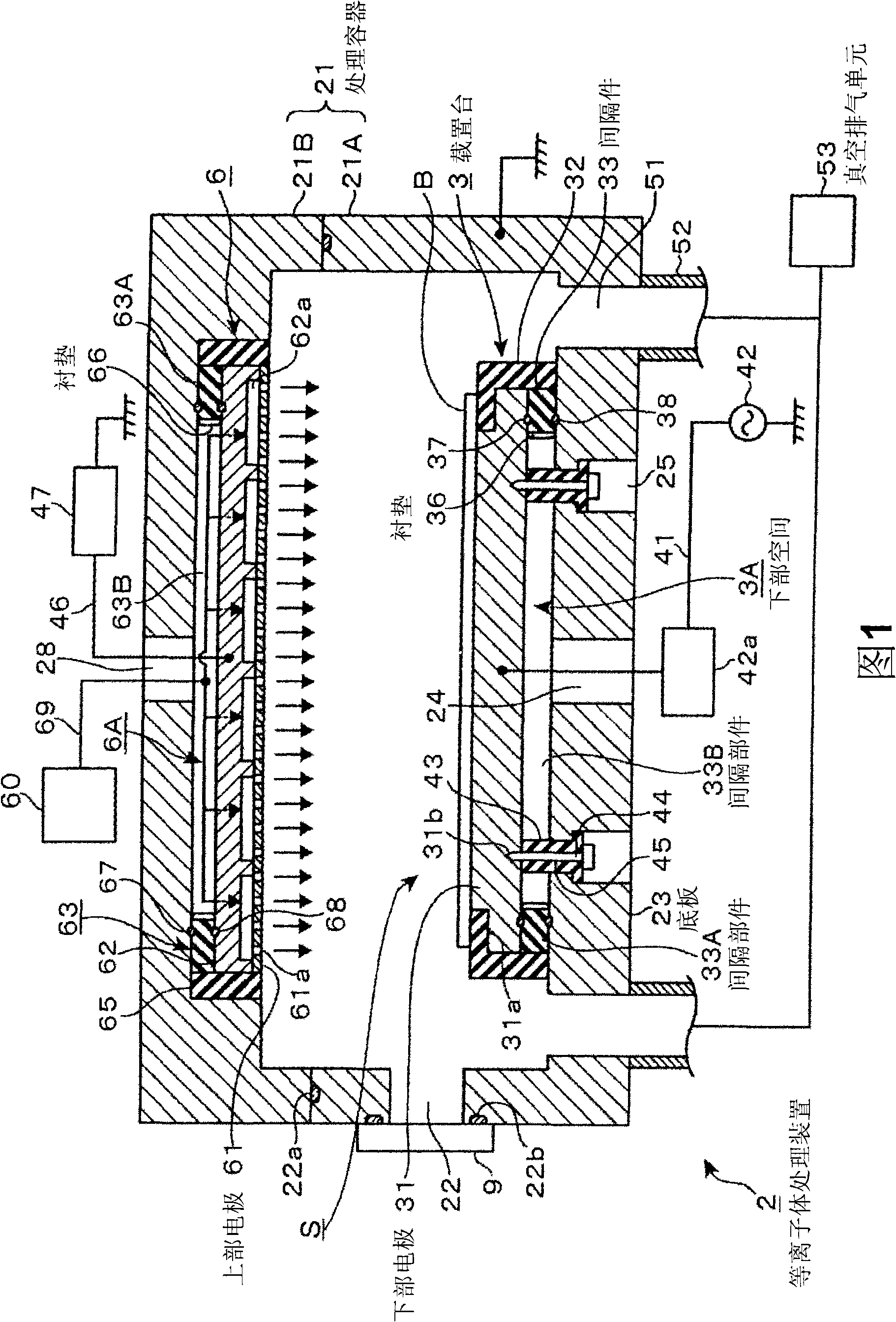

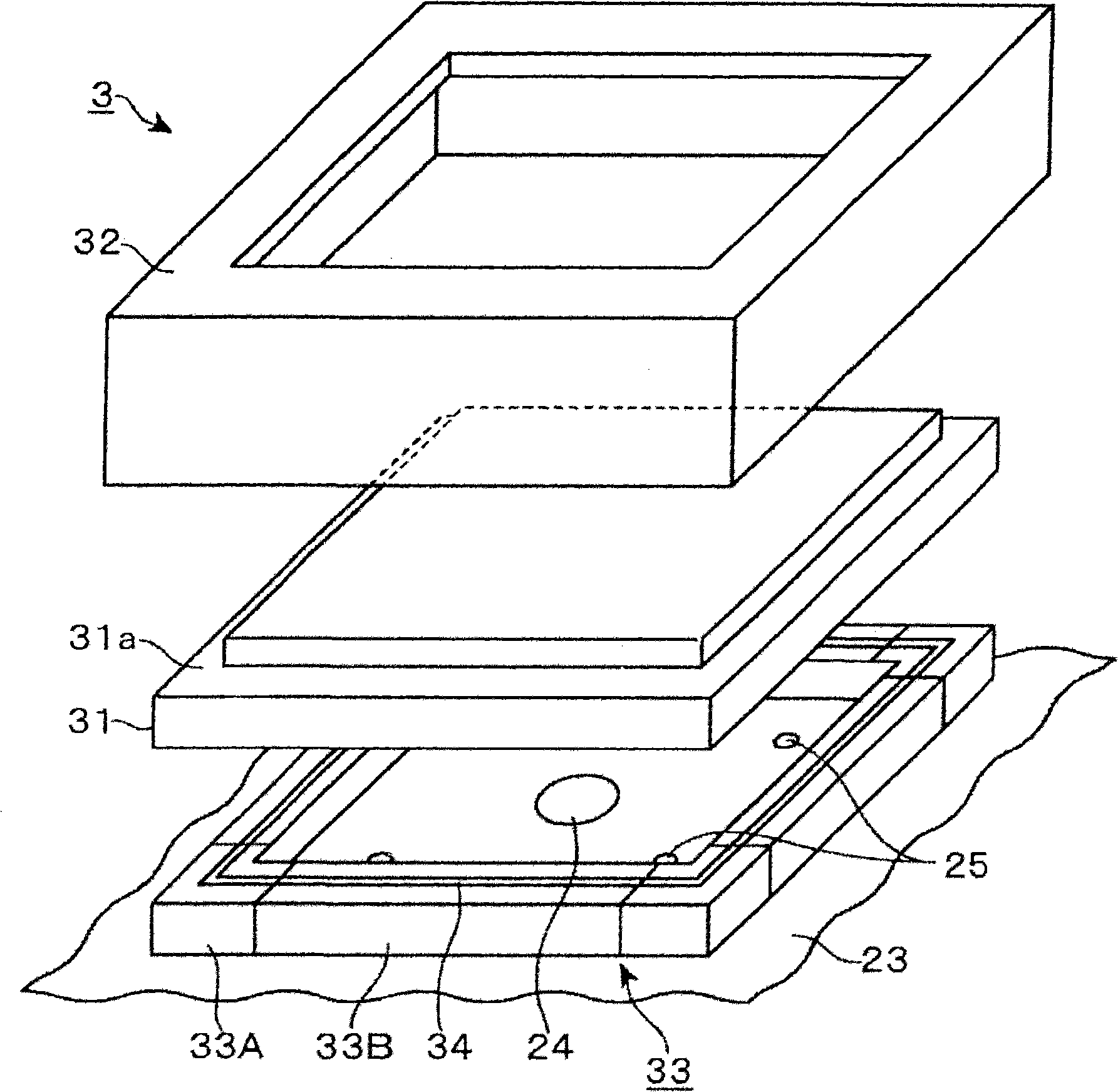

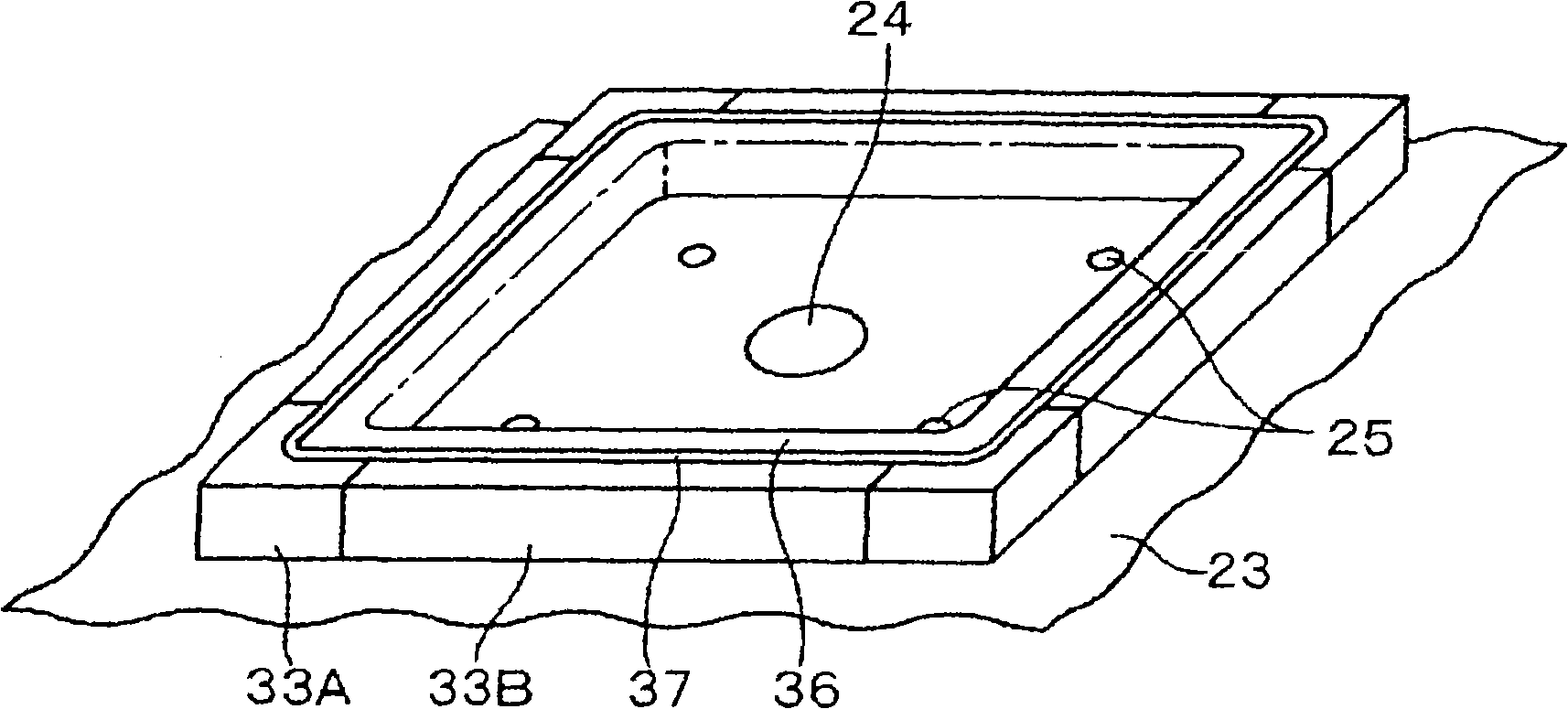

[0060] Hereinafter, an example in which the vacuum container of the present invention is applied to a plasma processing apparatus for etching an FPD substrate B will be described with reference to FIG. 1 . The plasma processing apparatus 2 of FIG. 1 has a grounded angular cylindrical processing container 21 for etching a substrate B, and this processing container 21 corresponds to a vacuum container within the scope of the invention. The processing container 21 is made of aluminum having a rectangular planar shape, has a container body 21A with an open top, and an upper cover 21B provided to close the top opening of the container body 21A. In order to maintain the airtightness of the processing space S in the processing container 21, the container main body 21A and the upper cover 21B are joined via an O-ring 22a. Moreover, the transfer port 22 of the board|substrate B is provided in the side wall of 21 A of container main bodies, and it is comprised so that opening and closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com