Motor vehicle braking system

A brake system and motor vehicle technology, applied in the direction of brakes, vehicle components, brake transmissions, etc., can solve the problems of not being used, etc., to improve operational reliability, save installation space and seals, and avoid technical complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

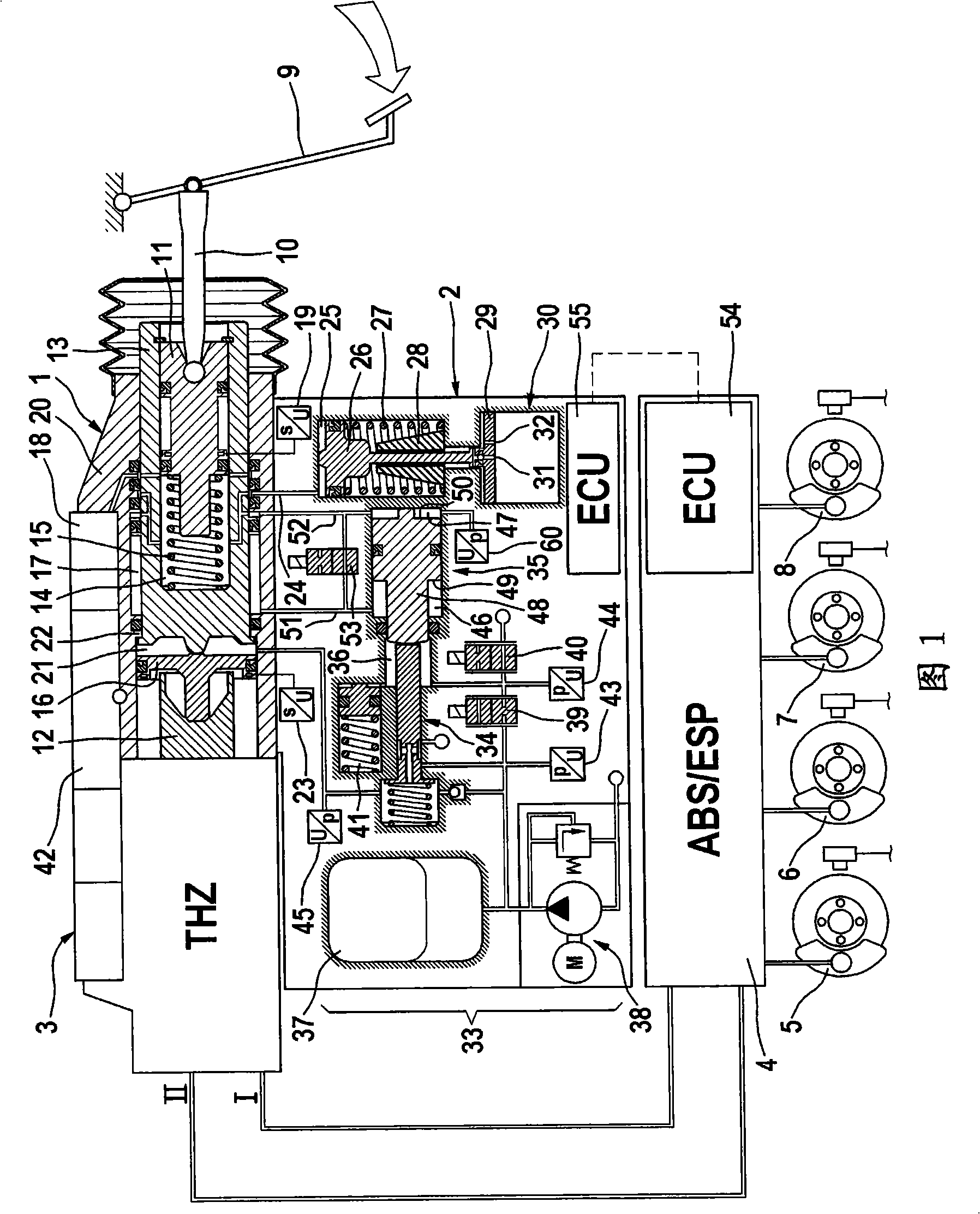

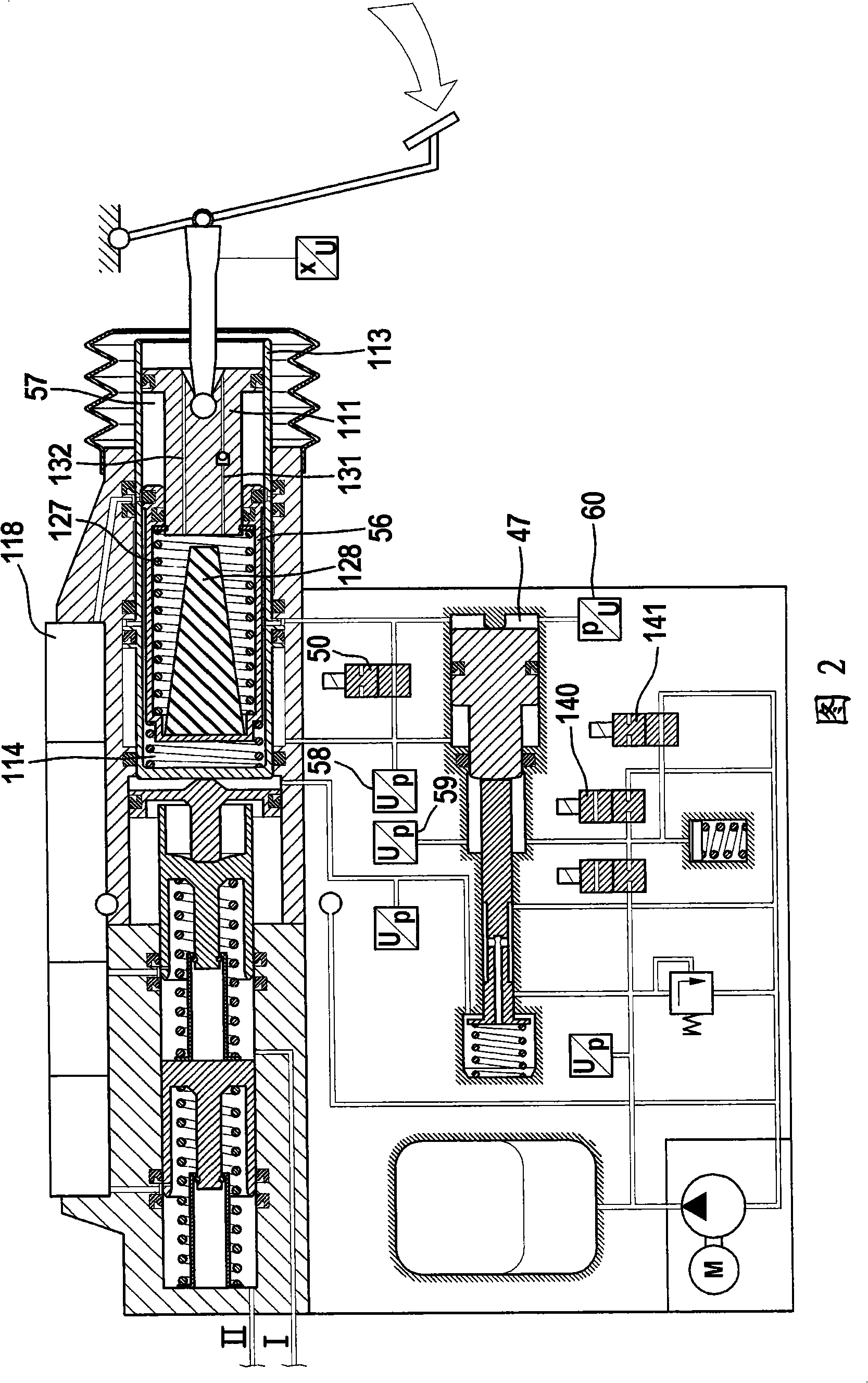

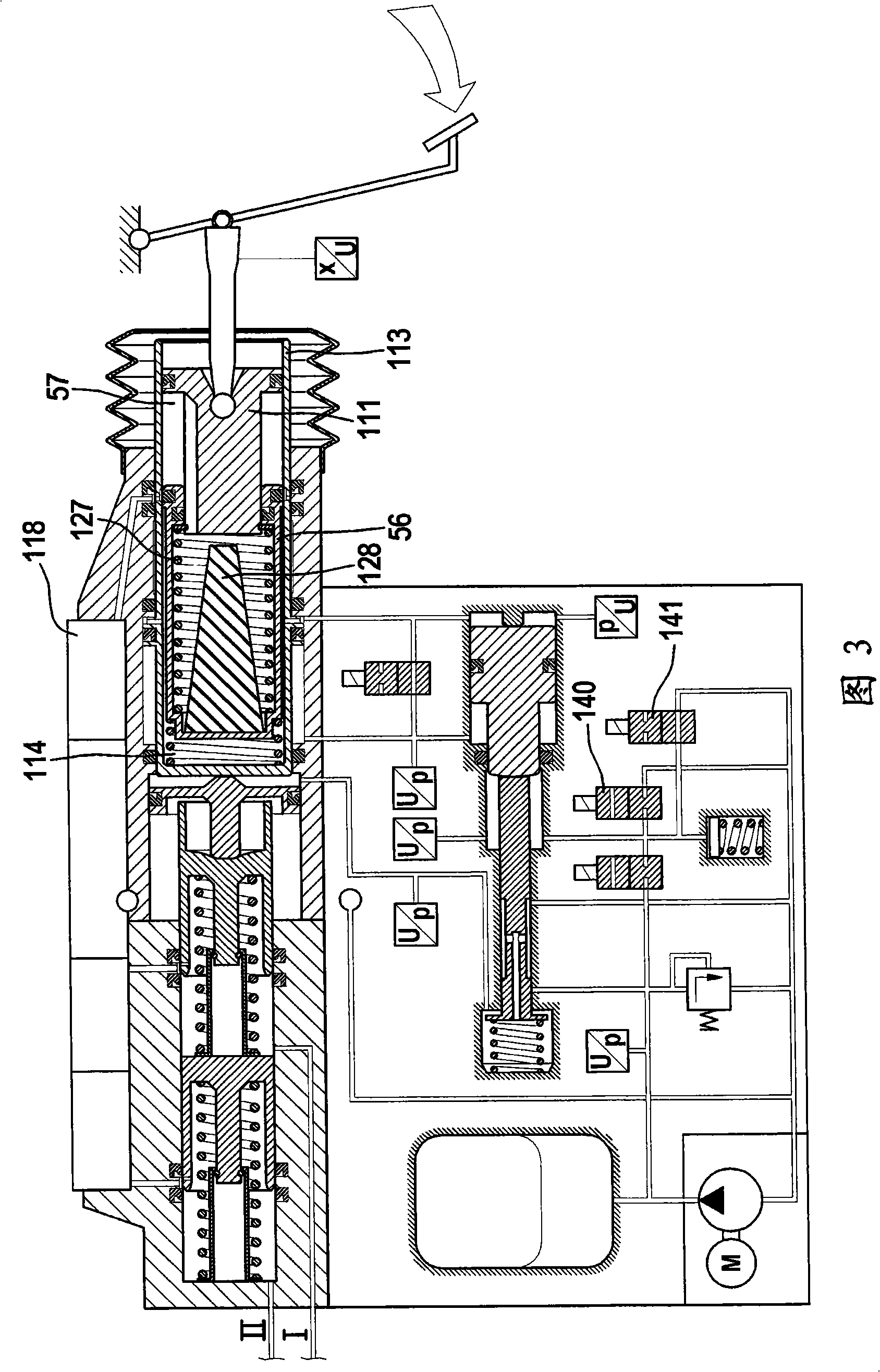

[0029] The brake system according to the invention shown in the figure essentially comprises an actuating device 1, a hydraulic control unit 2 and a brake master cylinder or tandem (brake) master cylinder 3, wherein the actuating device and the control unit Forms a brake booster, the brake master cylinder or tandem (brake) master cylinder is operatively arranged downstream of the brake booster and is connected in its pressure chamber, not shown, to the wheel brake circuits I, II , these wheel brake circuits supply the wheel brakes 5-8 of the motor vehicle with hydraulically pressurized fluid in connection with known ABS / ESP hydraulic assemblies or controllable wheel brake pressure modulation modules 4 . The wheel brake pressure modulation module 4 is associated with an electronic control and regulation unit 54 . The actuating device 1 housed in a housing 20 connected to the tandem master cylinder 3 can be driven by means of a brake pedal 9 which acts on the first piston 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com