Door stay with support housing

A technology for supporting shells and shells, which is applied in the direction of manufacturing tools, multi-purpose hand tools, fastening devices for wings, etc., and can solve the problems of entering the car body plate and supporting the shell structure without optimal adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

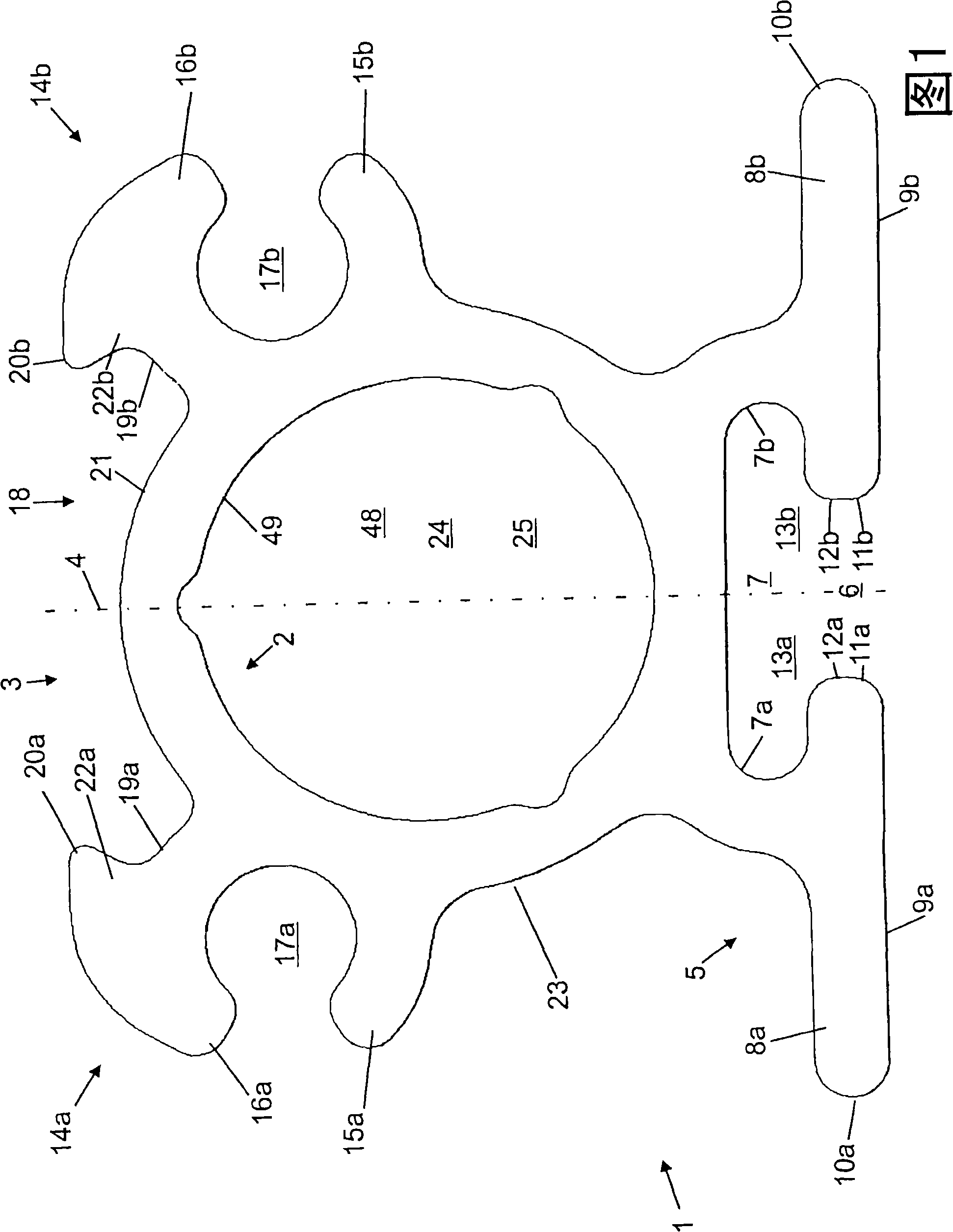

[0025] FIG. 1 shows a plan view of an extrusion profile 1 , which extends approximately perpendicular to the paper and has an inner profile 2 and an outer profile 3 . The extrusion profile 1 is mirror-symmetrical along an imaginary plane (line 4 in FIG. 1 ) perpendicular to the paper. The inner profile 2 is provided as a receptacle 48 for a movable part (not shown in FIG. 1 ), for which purpose the inner profile 2 has a generally circular side wall 49 surrounding the movable part on all sides. The extrusion profile has a generally circular outer profile 23 from which the first profile portion 5, the second profile portion 14 and the third profile portion 18 protrude outwards such that the wall thickness is There is no reduction at the position of one of the profile parts 5, 14 or 18.

[0026] The outer profile 3 of the extruded profile 1 comprises a first profile part 5 having a receiving opening 6, a receiving space 7 and two support parts 8a, 8b, the receiving space 7 being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com