Tobacco mixed ligand distribution device and method using the device to distribute material

A cloth device and tobacco technology, which is applied in the tobacco industry, can solve the problems of less or more tobacco materials, difficult travel time, and failure to ensure the uniformity of tobacco mixing, and achieve stable effects, improved effects, and improved uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

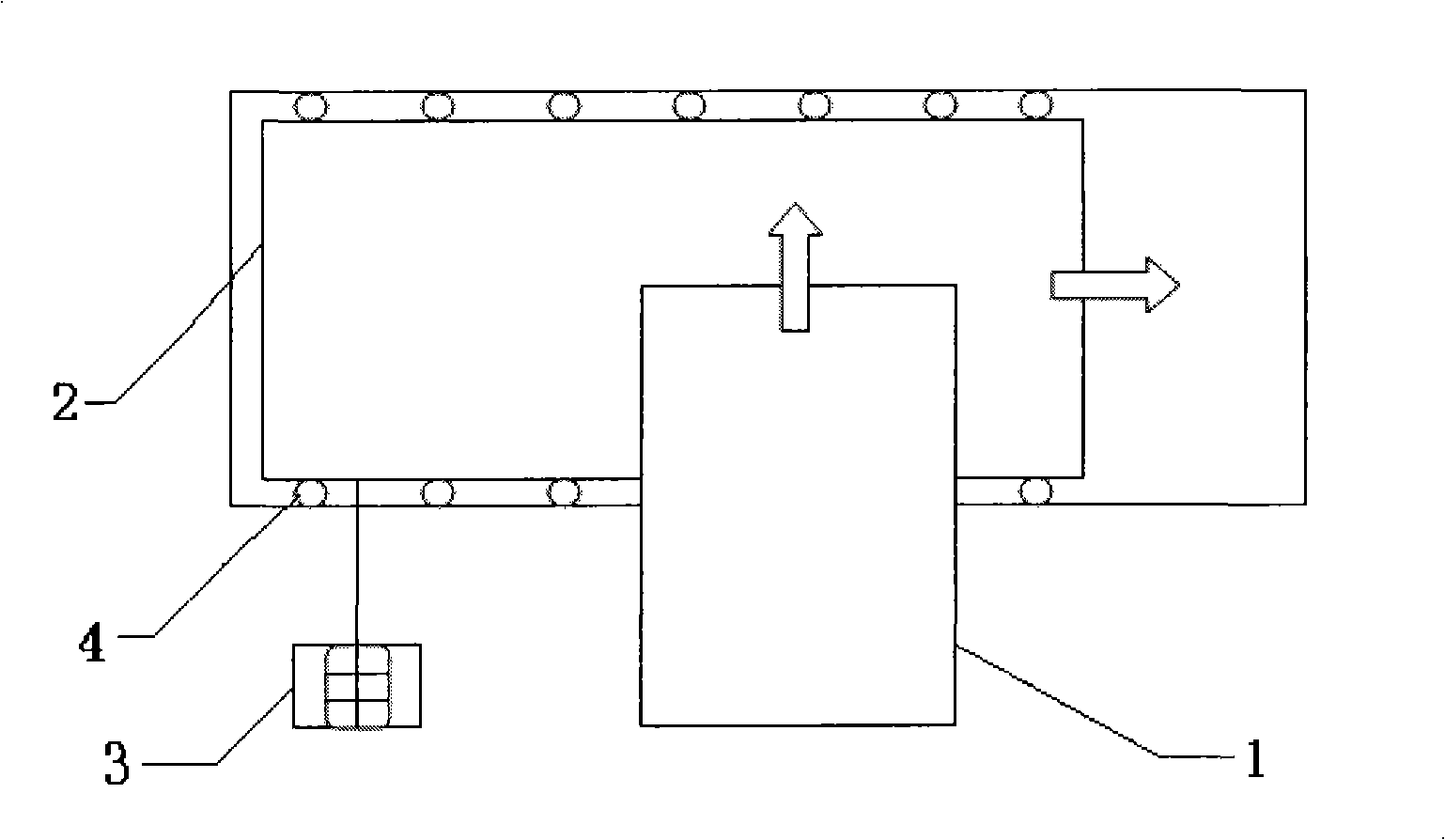

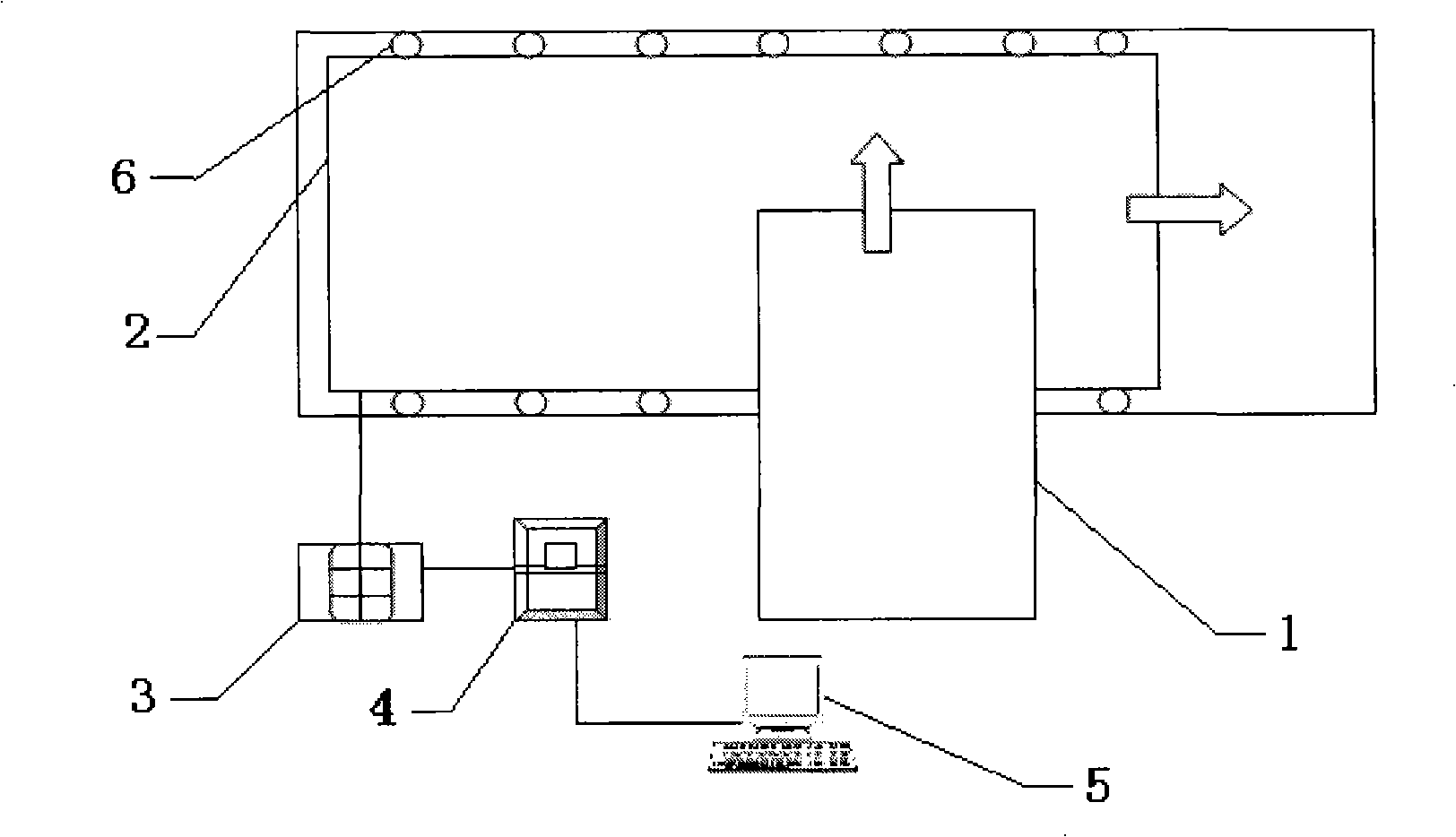

[0013] The distribution device for tobacco mixing of the present invention comprises a longitudinal distributing vehicle 1 and a horizontal distribution vehicle 2, rollers 6 are arranged on the distribution vehicle 2, a transmission motor 3 is arranged on the distribution vehicle, and the transmission motor is connected to a frequency conversion device 4. The frequency conversion device is connected with the computer control system 5, and the speed of the rollers 6 of the distribution vehicle can be changed through the adjustment of the frequency conversion.

[0014] Utilize the present invention to carry out concrete working steps as follows:

[0015] 1. When the tobacco material begins to fall into the cloth cart, collect the flow of tobacco material, which is recorded as G 0 .

[0016] 2. After the production runs for a period of time, the tobacco flow is collected again, which is recorded as G 1 , which is entered into the computer system.

[0017] 3. According to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com