Aerogel Body Armor

An aerogel and bulletproof vest technology, applied in protective clothing, protective equipment, protective equipment and other directions, can solve the problems of inability to buffer the kinetic energy of bullets, heavy weight and high cost of bulletproof vests, and achieve good ballistic resistance and improve the effect of ballistic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

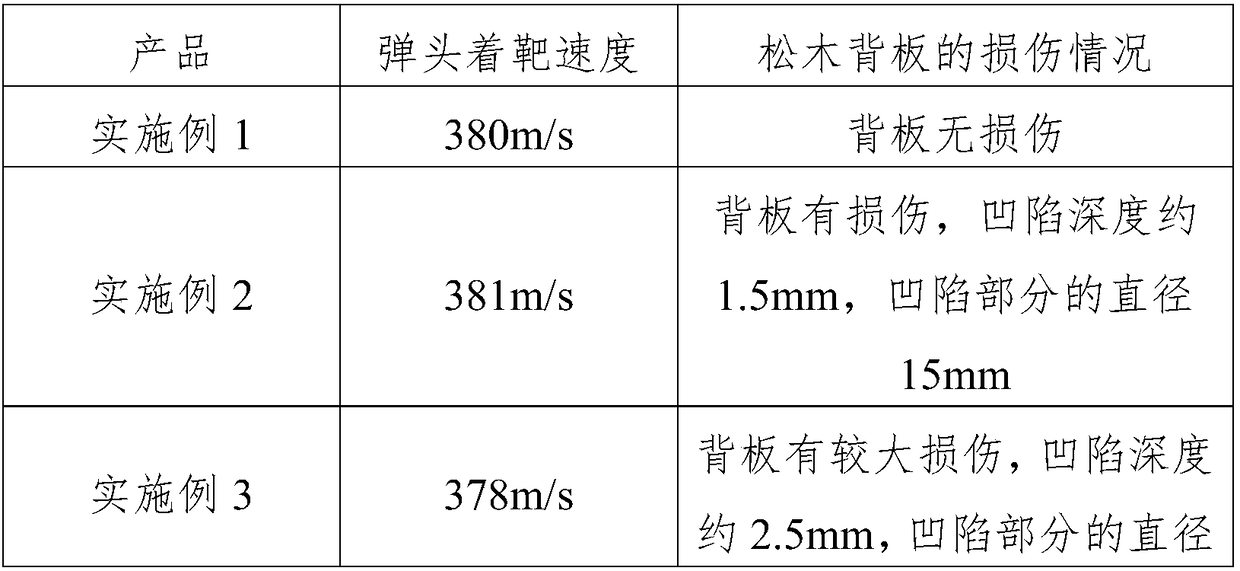

Embodiment 1

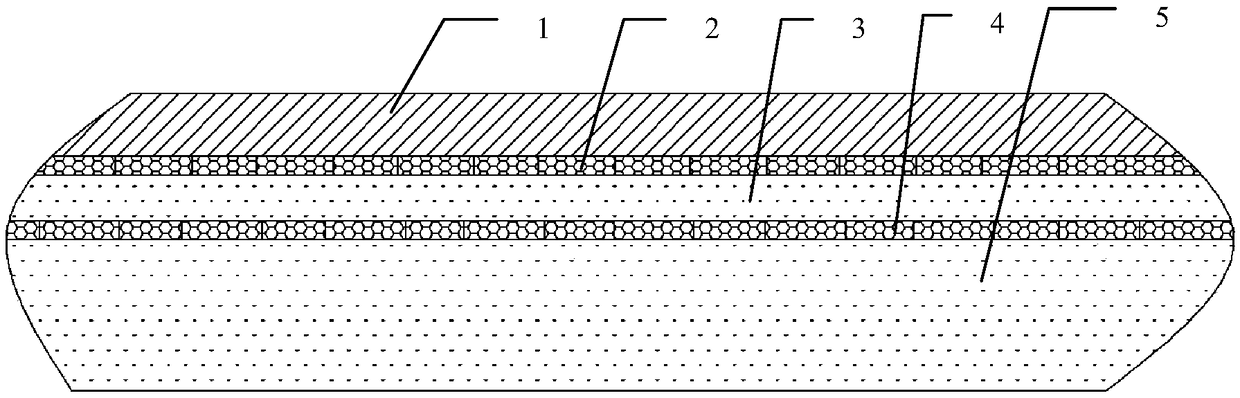

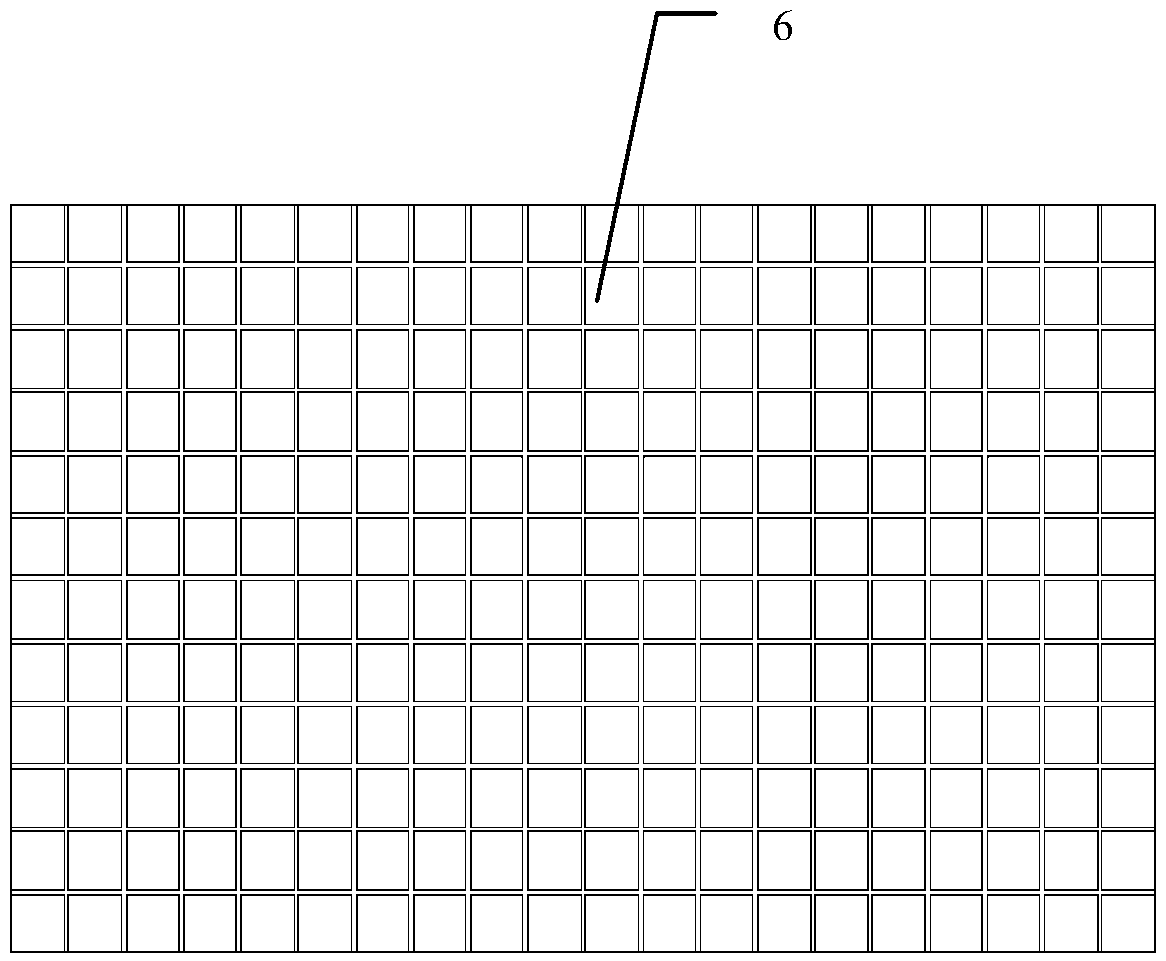

[0022] refer to figure 1 class figure 2 , the preferred embodiment 1 of the present invention provides an airgel body armor, which consists of a bulletproof fiber layer 1, a first bulletproof plate layer 2, a first airgel layer 3, and a second bulletproof plate layer 4 arranged sequentially from outside to inside. , the second airgel layer 5, and the layers are bonded together by adhesive; the first bulletproof plate layer and the second bulletproof plate layer are assembled by several bulletproof blocks 6, and the bulletproof plate layer of the first bulletproof plate layer The block is an open-cell foam metal block, and the bullet-proof block of the second bulletproof plate layer is a closed-cell foam metal block; the porosity of the second airgel layer is smaller than that of the first airgel layer, and the first airgel layer The thickness of the gel layer was 4 mm and the thickness of the second airgel layer was 10 mm.

[0023] The bulletproof block is a square with a t...

Embodiment 2

[0030] An airgel bulletproof vest is composed of a bulletproof fiber layer, a first bulletproof plate layer, a first airgel layer, a second bulletproof plate layer, and a second airgel layer arranged sequentially from the outside to the inside. Bonded together by adhesive; the first bullet-proof board layer and the second bullet-proof board layer are assembled by several bullet-proof blocks, the bullet-proof block of the first bullet-proof board layer is an open-cell foam metal block, and the bullet-proof board layer of the second bullet-proof board layer The bulletproof block is a closed-cell foam metal block; the porosity of the second airgel layer is less than that of the first airgel layer, and the thickness of the first airgel layer is 2mm, and the second airgel layer The thickness is 10mm.

[0031] The bulletproof block is a square with a thickness of 3mm and a side length of 1cm.

[0032] The pore diameter of the open-cell metal foam block and the closed-cell foam meta...

Embodiment 3

[0038] An airgel bulletproof vest is composed of a bulletproof fiber layer, a first bulletproof plate layer, a first airgel layer, a second bulletproof plate layer, and a second airgel layer arranged sequentially from the outside to the inside. Bonded together by adhesive; the first bullet-proof board layer and the second bullet-proof board layer are assembled by several bullet-proof blocks, the bullet-proof block of the first bullet-proof board layer is an open-cell foam metal block, and the bullet-proof board layer of the second bullet-proof board layer The bulletproof block is a closed-cell foam metal block; the porosity of the second airgel layer is less than that of the first airgel layer, the thickness of the first airgel layer is 4mm, and the second airgel layer The thickness is 10mm.

[0039] The bulletproof block is a square with a thickness of 1.5 mm and a side length of 1 cm.

[0040] The pore diameter of the open-cell metal foam block and the closed-cell foam meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com