Tuning vibration absorption device

A technology of constrained layers and connectors, which is applied to building components, earthquake resistance, etc., can solve the problem that tuned mass dampers cannot handle high-frequency vibrations of building structures well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

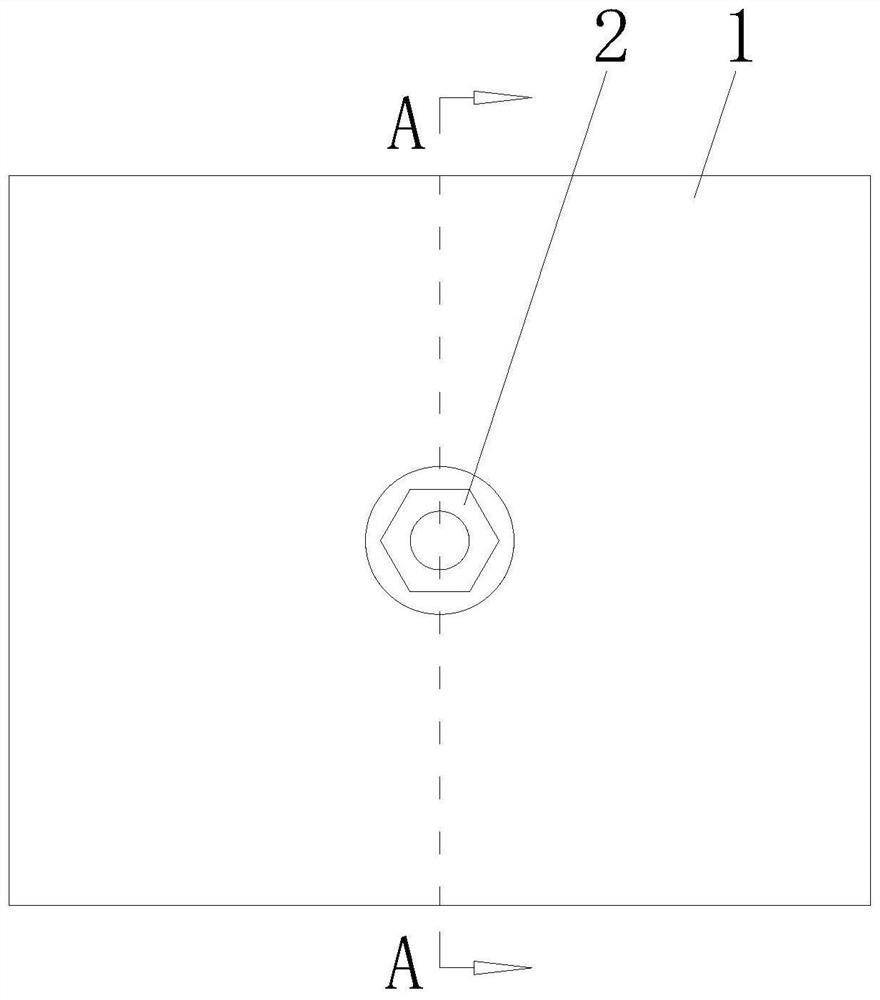

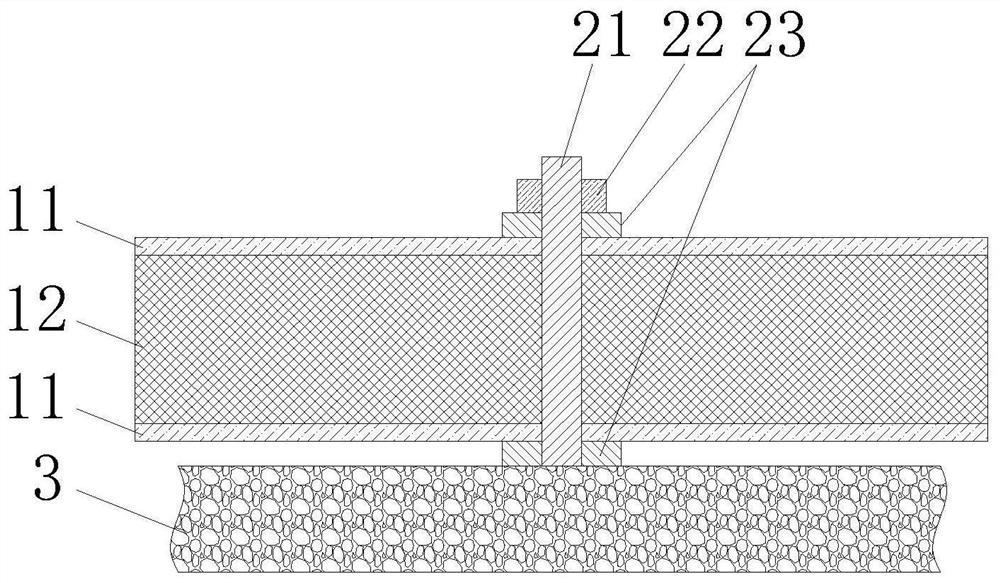

[0033] A tuned vibration absorbing device such as figure 1 and figure 2 As shown, it includes a vibration-absorbing unit 1 and a connection structure 2 for connecting the vibration-absorbing unit 1 .

[0034] Wherein, the vibration-absorbing unit 1 includes two oppositely arranged constrained layers 11 and a constrained layer 12 sandwiched between the two constrained layers 11, the constrained layer 12 is made of a damping material, such as high damping polyurethane or rubber, and the constrained layer 11 is usually made of rigid material, such as steel or aluminum alloy. Moreover, the constrained layer 11 and the constrained layer 12 are closely connected, for example, by adhesive bonding, so as to avoid slippage between the two.

[0035] The connecting structure 2 includes connecting pieces 21 , fasteners 22 and gaskets 23 . Wherein, the gasket 23 has a through hole so as to be sleeved on the connector 21, and the gasket 23 is arranged on both sides of the vibration-abso...

Embodiment 2

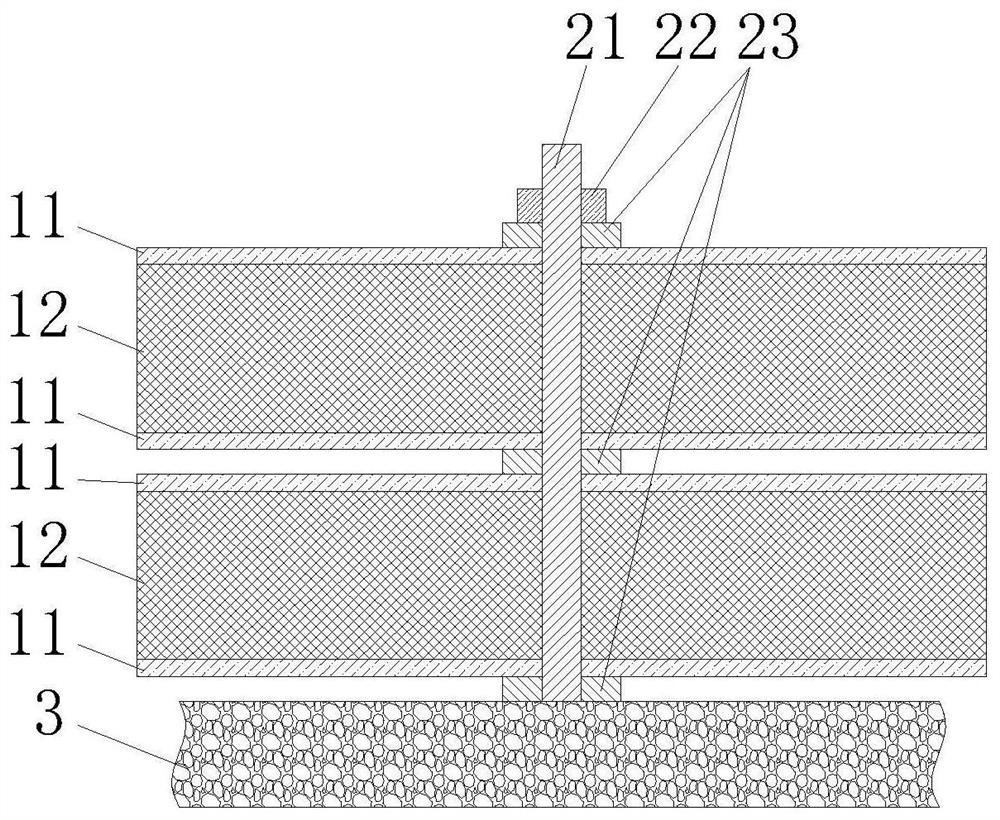

[0040] The difference between it and Embodiment 1 is: in this embodiment, if image 3 As shown, there are multiple (two or more) vibration-absorbing elements 1, and multiple vibration-absorbing elements 1 are stacked. There are gaps between the vibration-absorbing elements 1, so as to provide sufficient deformation space.

[0041] It can be understood that the arrangement of multiple vibration-absorbing elements 1 can improve the vibration-absorbing efficiency on the one hand, so that the vibration energy on the controlled structure 3 can be converted into heat energy by more vibration-absorbing elements 1, improving the vibration-absorbing efficiency; Adjust the size of each vibration-absorbing element 1 and the relationship between the thickness of each layer, so that each vibration-absorbing element 1 has a different frequency, so that the device has a larger vibration-absorbing frequency band, which is suitable for the vibration of each frequency that occurs on the control...

Embodiment 3

[0043] The difference between it and Embodiment 1 is: in this embodiment, if Figure 4 and Figure 5 As shown, the perforation 13 is elongated, so that a plurality of the above-mentioned connectors 21 are arranged at intervals in the perforation 13 along its length direction. The through hole that the connector 21 is compatible with. Moreover, when the vibration-absorbing element 1 is configured as a rectangle, the length direction of the through hole 13 is parallel to the side of the vibration-absorbing element 1 .

[0044] It can be understood that the through holes 13 may be integrally provided on the vibration absorbing element 1 , that is, the three layers of the vibration absorbing element 1 are provided with the through holes 13 opposite to each other. Such setting, on the one hand, enables the vibration on the controlled structure 3 to be more efficiently transmitted to the vibration-absorbing element 1; The setting of the component 21 makes the vibration absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com